Method for producing a water-tight plug connector

a plug connector and watertight technology, applied in the direction of couplings/cases, line/current collector details, coupling device connections, etc., can solve the problems of negative effects on the electrical and mechanical properties of the plug connector and the transmission of signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

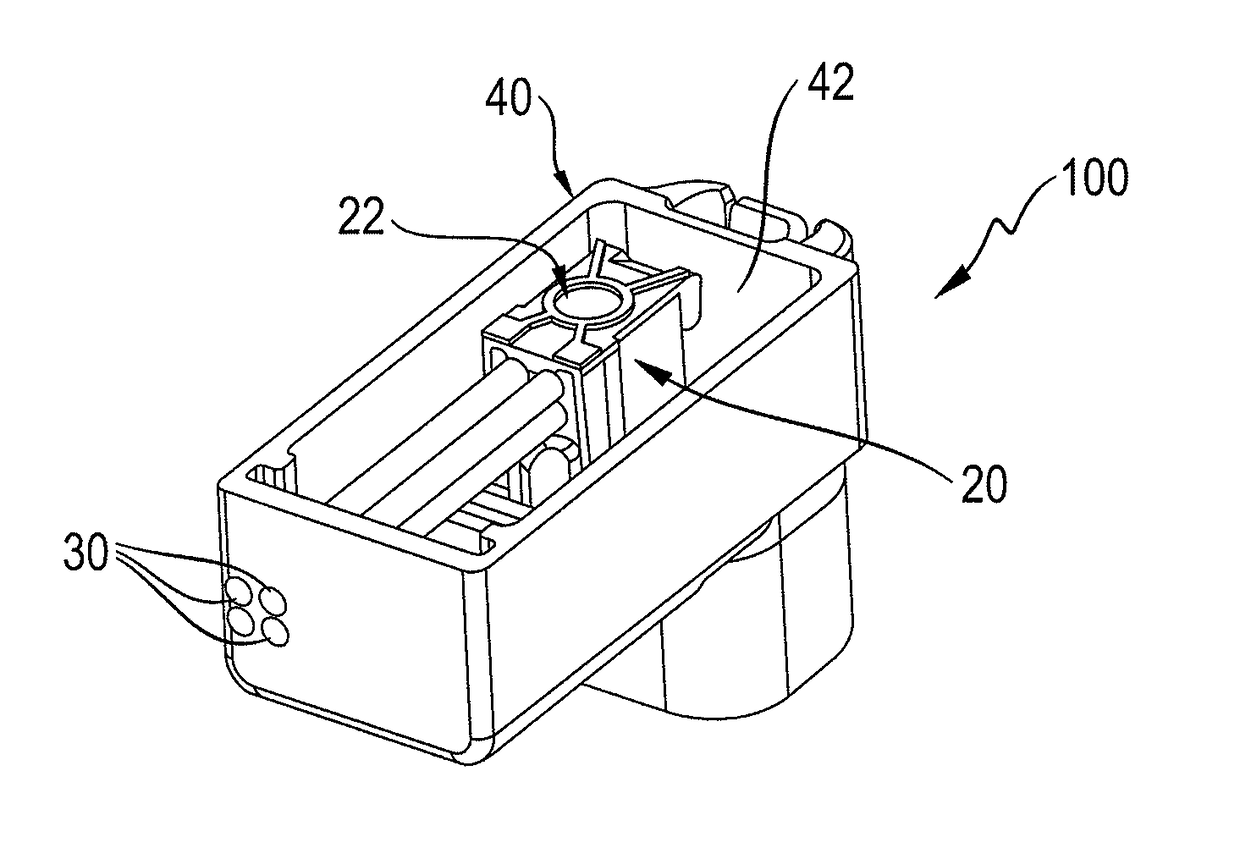

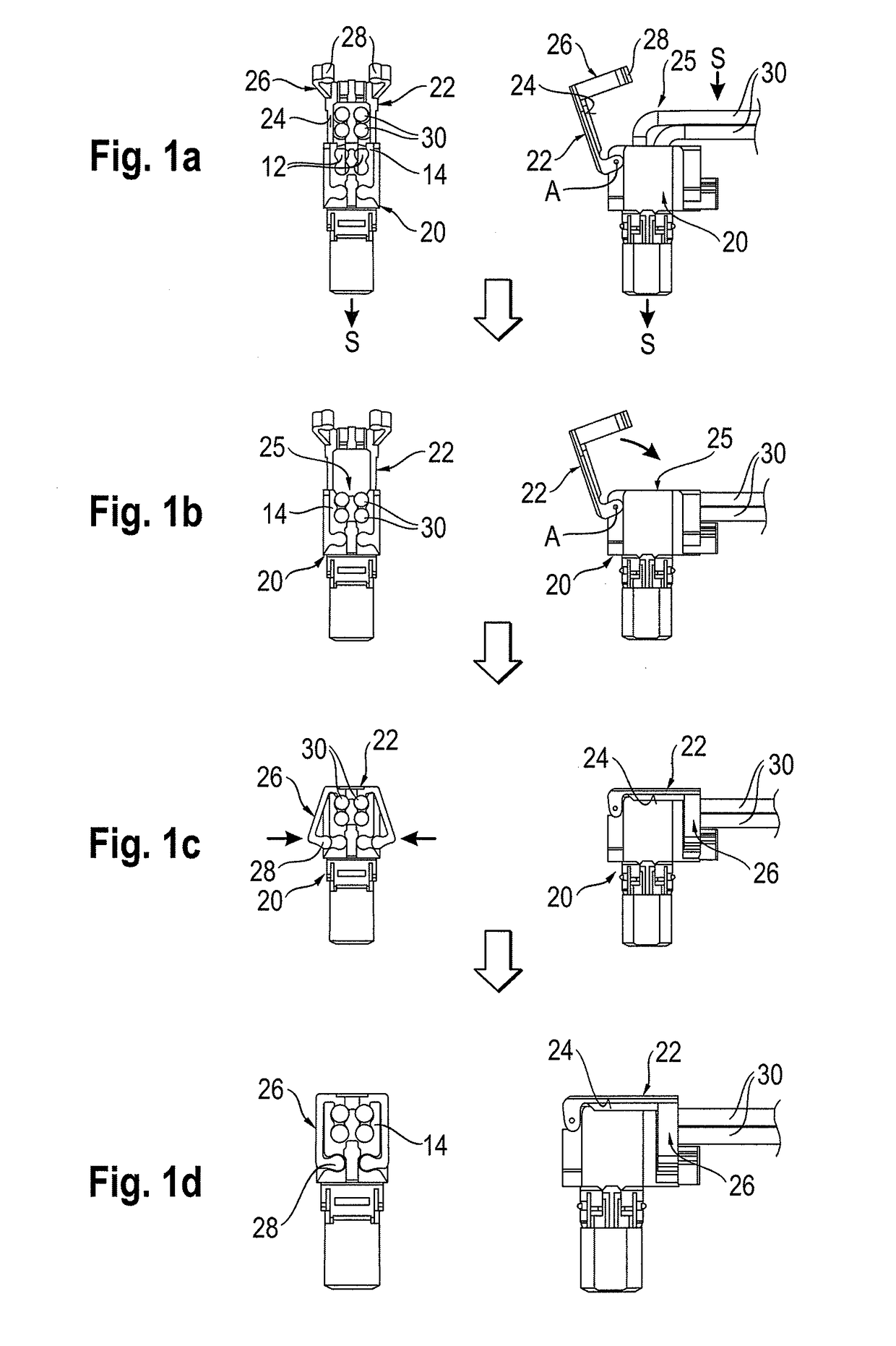

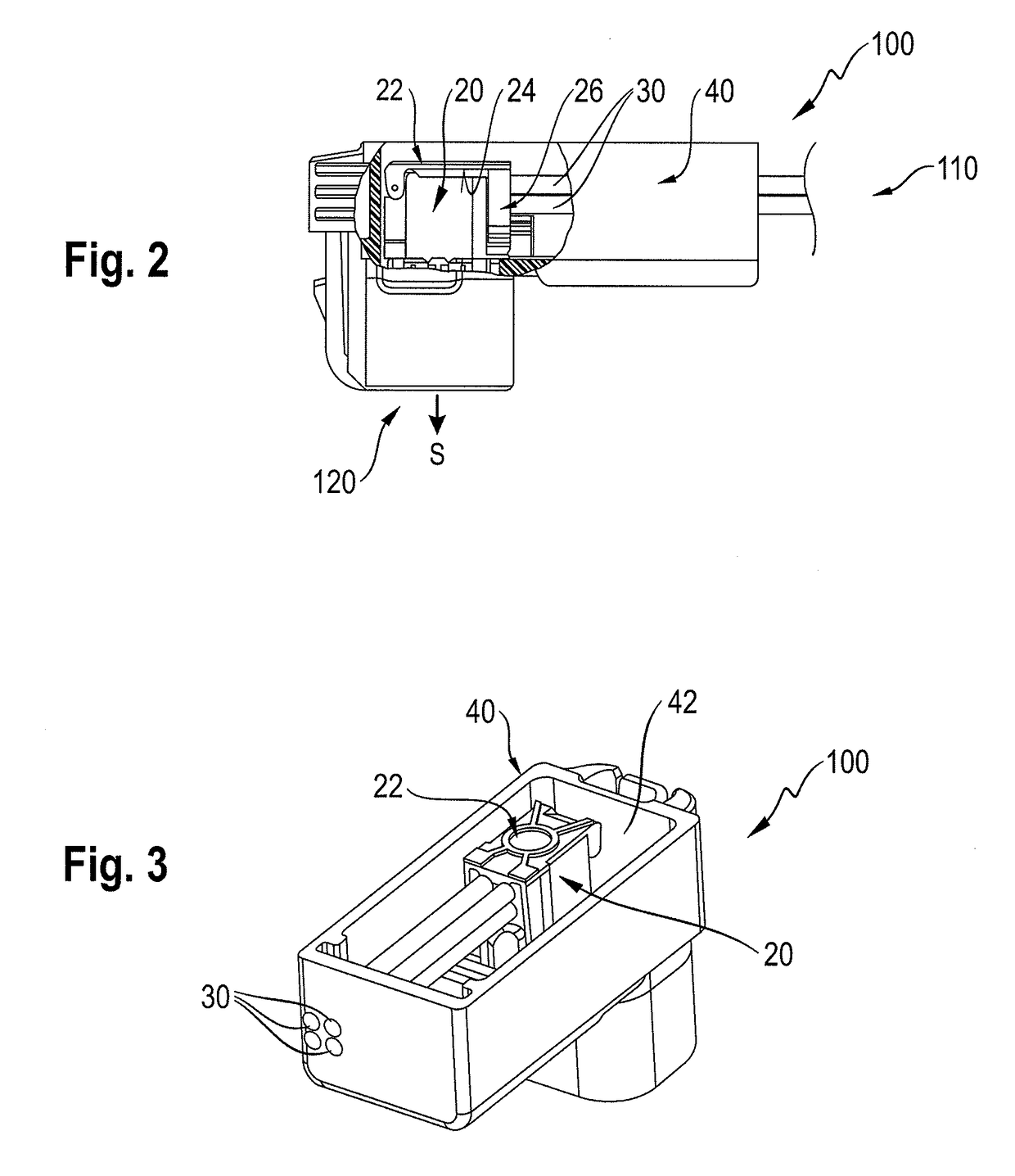

[0020]In describing the preferred embodiment of the present invention, reference will be made herein to FIGS. 1-3 of the drawings in which like numerals refer to like features of the invention.

[0021]The invention is based on the knowledge that, after a conductor has been introduced into the guide channel of the insulator part via a lateral opening, a paste-like or viscous sealing compound can, during filling, penetrate through the open lateral opening into the interior of the insulator part, as far as the guide channel, as a result of which the course of the conductor in the guide channel can be changed.

[0022]For example, the sealing compound which has penetrated into the guide channel undergoes a change in volume during the hardening process, as a result of which the conductor can be pressed mechanically against a wall of the guide channel or against the adjacent conductor. A change of the dielectric between several conductors and / or a change in the spacing between them through the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap