Advanced node cost reduction by ESD interposer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

examples

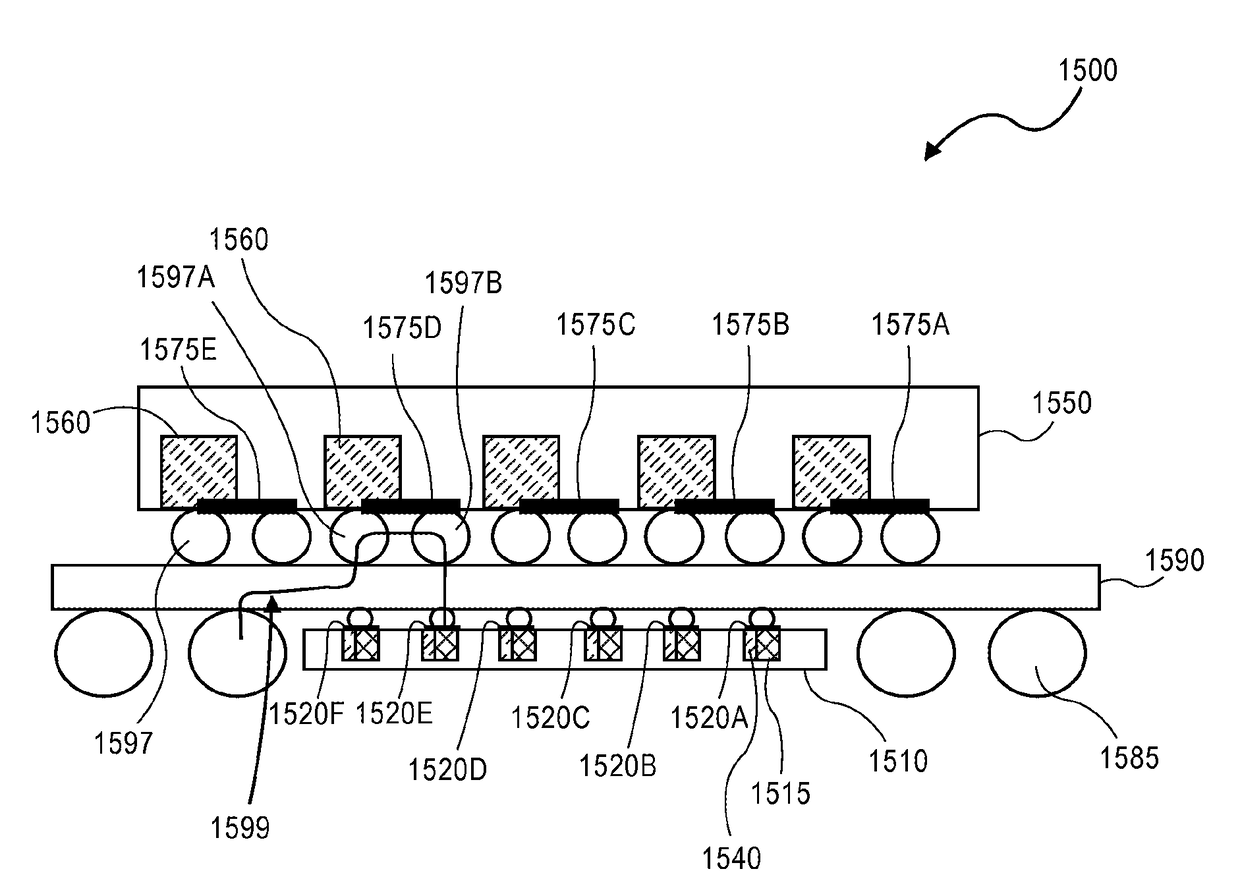

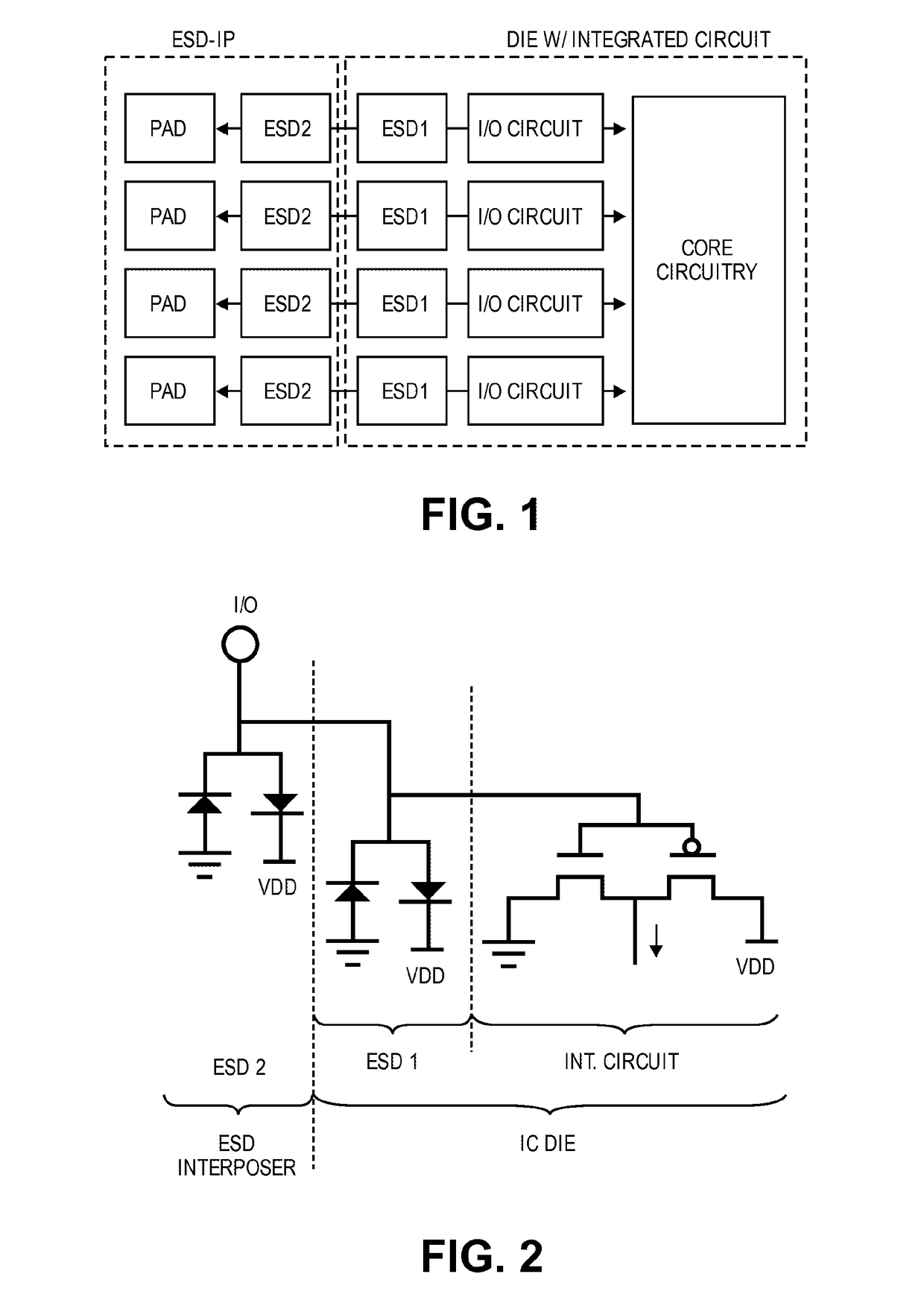

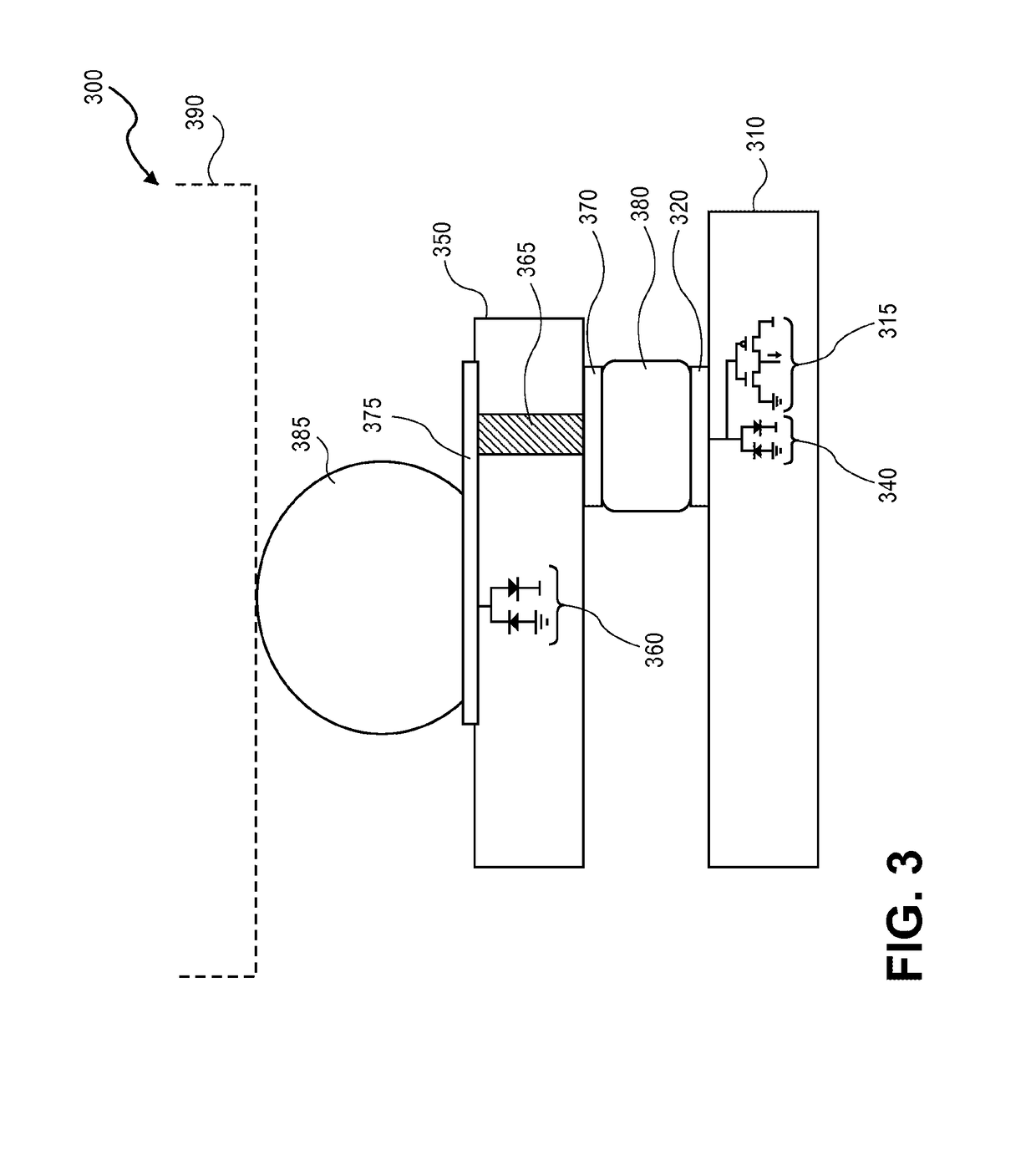

[0076]Example 1 is an apparatus including an electrostatic discharge circuit including a first circuit portion coupled beneath a die contact pad of an integrated circuit die and a second circuit portion in an interposer separate from the integrated circuit die, the interposer including a first contact point coupled to the contact pad of the integrated circuit die and a second contact point operable for connection to an external source.

[0077]In Example 2, the first circuit portion in the apparatus of Example 1 includes an ESD robustness that is different than an ESD protection robustness of the second circuit portion.

[0078]In Example 3, the first circuit portion in the apparatus of Example 2 includes a smaller maximum discharge current than a maximum discharge current of the second circuit portion and a failure threshold and failure threshold voltage of the second circuit portion is less than a failure threshold voltage of the first circuit portion.

[0079]In Example 4, the interposer in

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap