Spraying device for a construction machine for processing the ground, a construction machine with a spraying device and a method for operating a spraying device

a technology for construction machines and spraying devices, which is applied in the direction of roads, construction, and maintenance of roads, can solve the problems of fluid delivery apparatus clogging with ground material, inability to use for a long time, and insufficient precision in dosing, so as to effectively prevent the occurrence of pressure peaks during the changeover, the effect of reducing the pressure load on the line system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

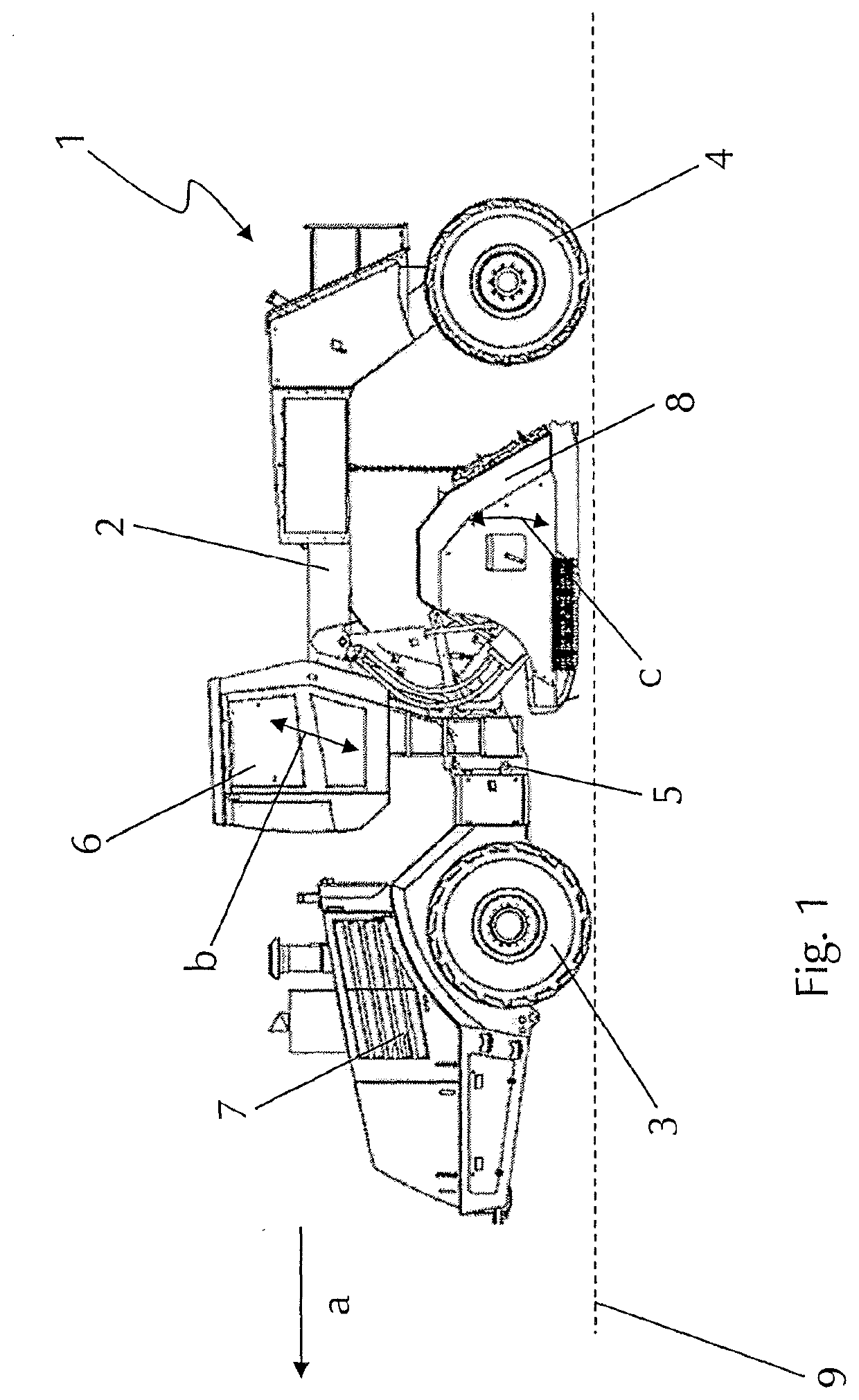

[0033]FIG. 1 relates to a construction machine 1, specifically in FIG. 1 a so-called stabilizer or a recycler, which depends on the respective application. The construction machine 1 comprises a machine frame 2, a pair of front wheels 3 and a pair of rear wheels 4, with merely the wheel disposed in the working direction a on the left side being visible. The machine frame 2 has a two-element configuration comprising two frame elements which are connected with each other by a knee-joint connection 5. A driver's cabin 6 is arranged at the level of the knee-joint connection 5, which cabin is height-adjustable along the direction of arrow b. The required drive power is provided by means of a drive apparatus 7 which provides the drive power required both for driving the construction machine 1 and for driving the working device which will be explained below in closer detail. The construction machine 1 is used for processing ground or road surfaces and the working device comprises a working ro

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap