Electronic component device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

PREFERRED EMBODIMENT

1. BASIC STRUCTURE

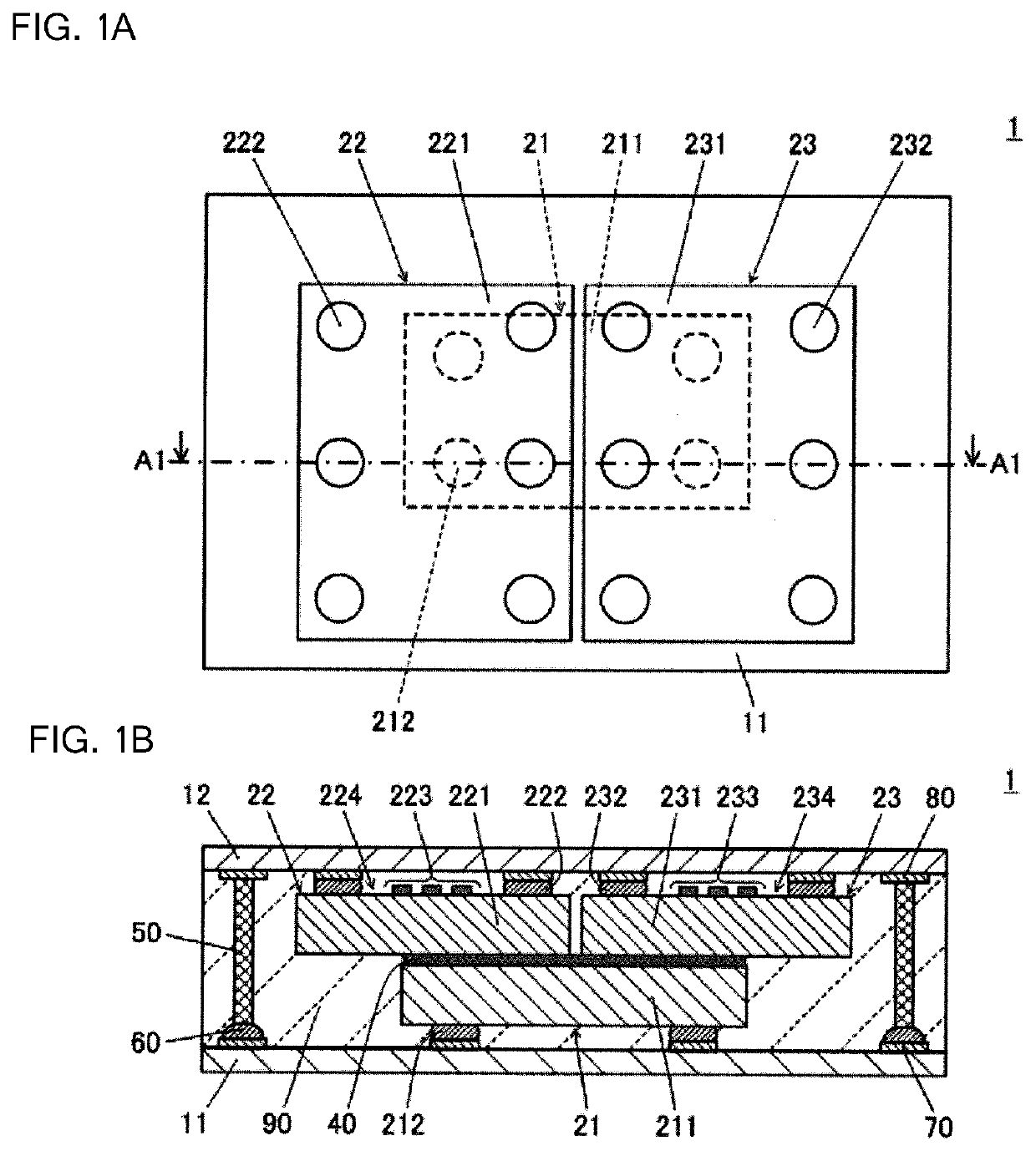

[0058]FIGS. 1A and 1B illustrate the structure of an electronic component device (module) 1 according to a preferred embodiment of the present invention. FIG. 1A is a plan view of the electronic component device 1. FIG. 1B is a cross-sectional view taken along an arrowed line A1-A1 in FIG. 1A.

[0059]In the following, for convenience of description, an electronic component 21 will be referred to as “first electronic component”, an electronic component 22 will be referred to as “second electronic component”, and an electronic component 23 will be referred to as “third electronic component”.

[0060]As illustrated in the plan view of FIG. 1A, the electronic component device 1 includes the first electronic component 21, the second electronic component 22, and the third electronic component 23. As will be described later, the first electronic component 21 includes a first base body 211, and a first outer terminal 212, which is an outer terminal of the first

example 1

A. Example 1

[0081]First, the following describes, as an electronic component device according to an Example 1 of a preferred embodiment of the present invention, an electronic component device in which at least two electronic components among the first electronic component 21, the second electronic component 22, and the third electronic component 23 are acoustic wave components or semiconductor components. Example 1 represents a case with a restriction placed on the type of each electronic component provided in the electronic component device 1 according to the basic structure. Accordingly, the same reference signs as those used for the electronic component device 1 according to the basic structure will be used in the following description.

I. First Aspect

[0082]In an electronic component device according to a first aspect of the Example 1, the first electronic component 21 is a semiconductor component, and the second electronic component 22 and the third electronic component 23 are acou

example 2

B. Example 2

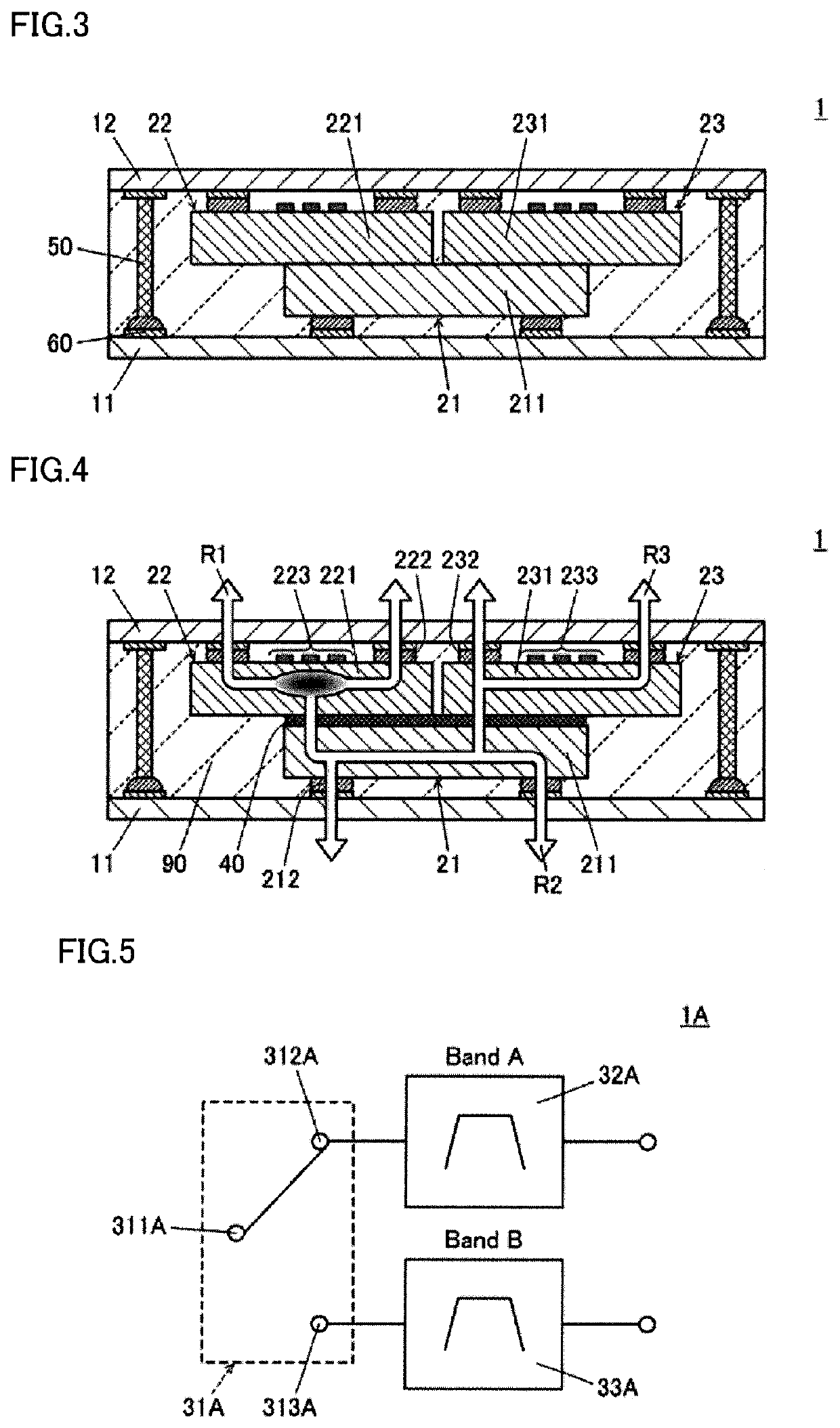

[0093]The following describes, with reference to FIGS. 5 to 10, an electronic component device according to an Example 2 in which the first electronic component 21 is a switching component and the second electronic component 22 and the third electronic component 23 are filter components. The aspects of Example 2 described below each represent an example in which the electronic component device 1 according to the basic structure is an electronic component device 1A, 1B, 1C, or 1D including a switching function and a filter function.

I. First Aspect

[0094]First, an electronic component device 1A according to a first aspect of the Example 2 will be described with reference to FIGS. 5 and 6. The electronic component device 1A according to the first aspect has a switching function to perform switching for two filter components among three electronic components that define an aggregate.

[0095]FIG. 5 is a circuit diagram illustrating a circuit provided in the electronic component dev

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap