Air-vapor separation device for separating air from refrigerant vapor and method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

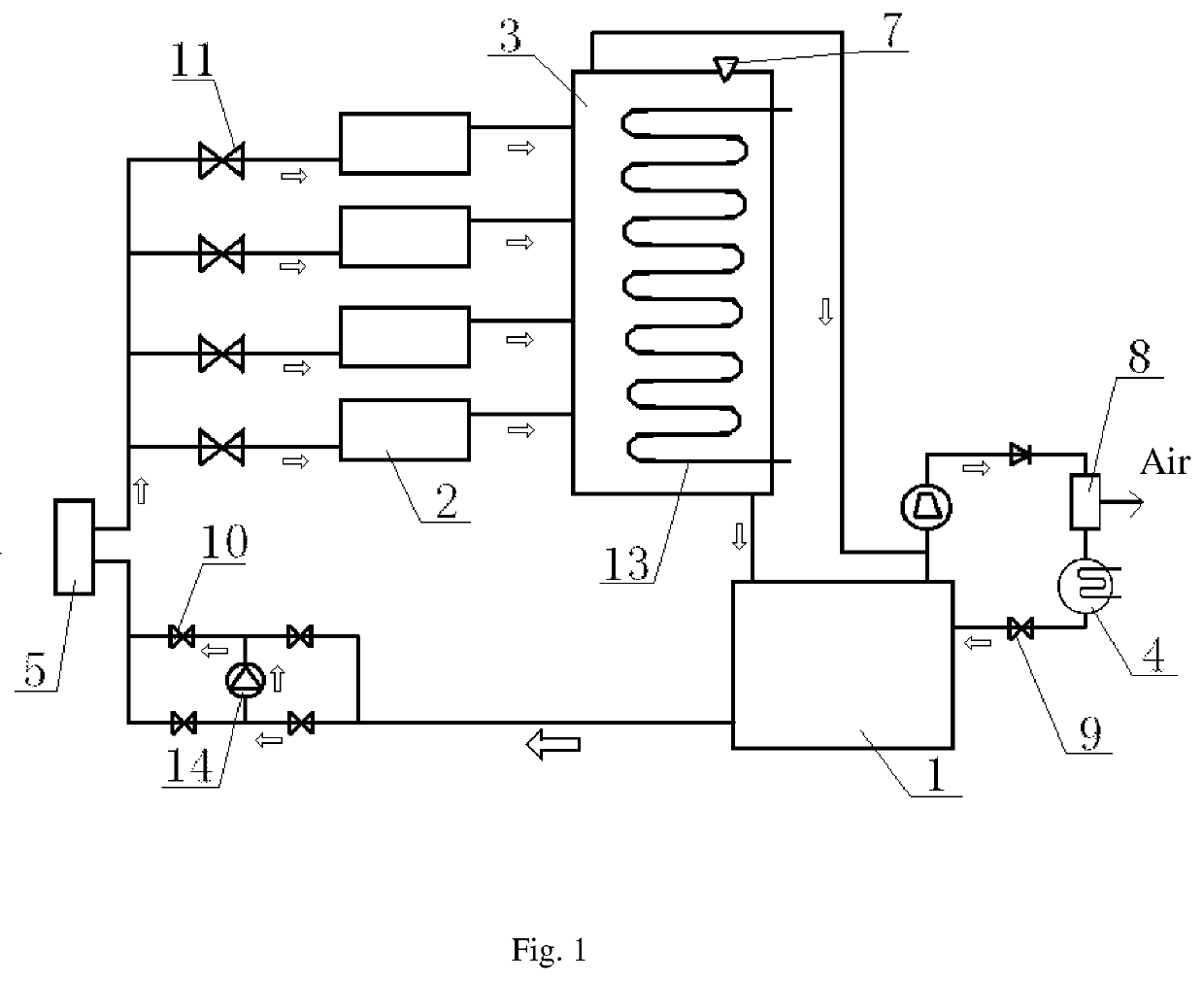

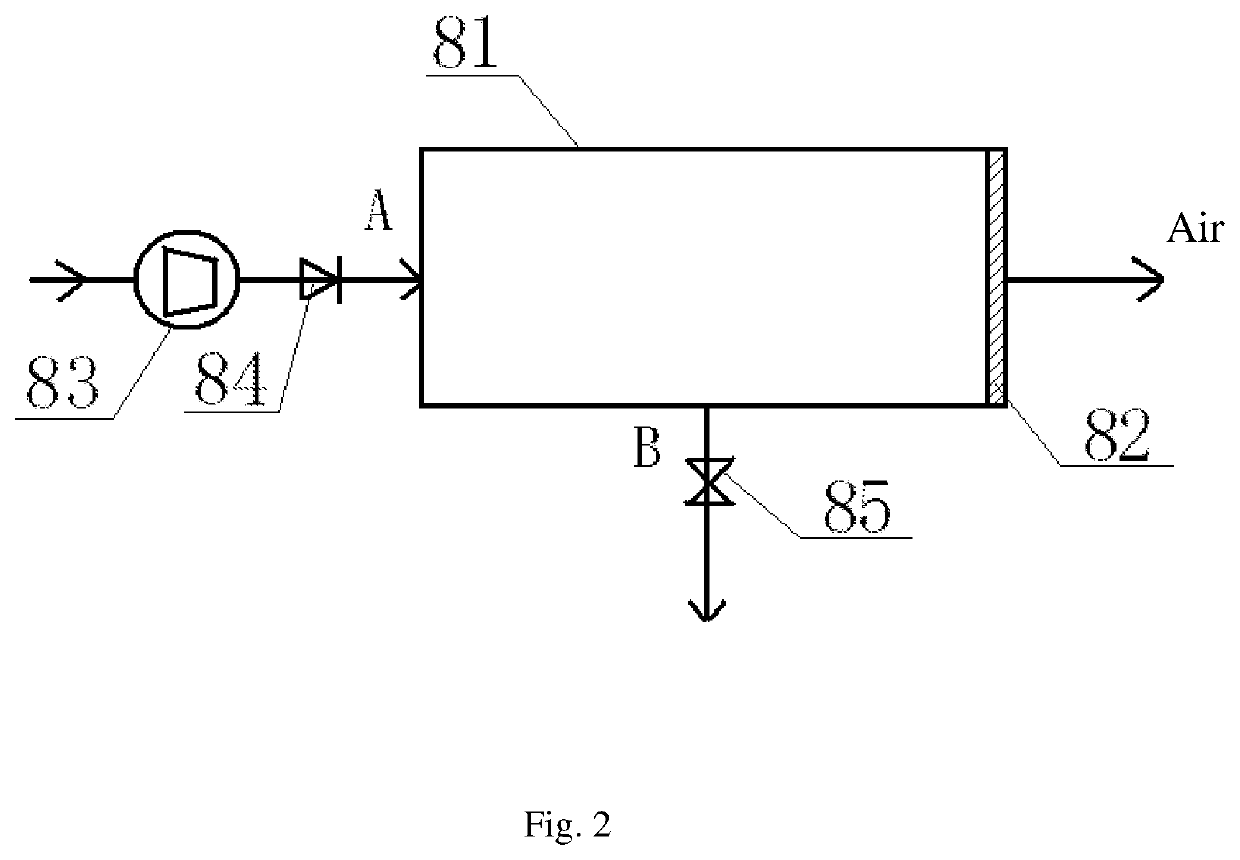

[0023]Description of reference numerals: 1—refrigerant storage tank, 2—immersed blade cabinet, 3—first condenser, 4—second condenser, 5—drying filter, 7—first pressure relief valve, 8—air-vapor separation device, 81—air-vapor separation tank, 82—air-vapor separation membrane, 83—compressor, 84—first control valve, 85—second control valve, 9—first on-off valve, 10—second on-off valve, 11—third on-off valve, 13—condensation coil, 14—refrigerant delivery pump.

DETAILED DESCRIPTION OF THE PREFERRED EXAMPLES

[0024]To make the purpose, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be described below in detail in combination with the drawings. It should be noted that, in the case of no conflicts, the embodiments in the present invention and features in the embodiments can be combined mutually and arbitrarily.

[0025]According to an embodiment of the present invention, an immersed liquid-cooling system directly immerses a server

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap