Preparation process for graphene resonant gas sensor based on doped metal atoms

a technology metal atoms, applied in the field of sensors, can solve the problems of poor contact, low sensitivity, etc., and achieve the effect of low sensitivity and low quality of graphene resonant gas sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0033]Specific implementation steps are as follows:

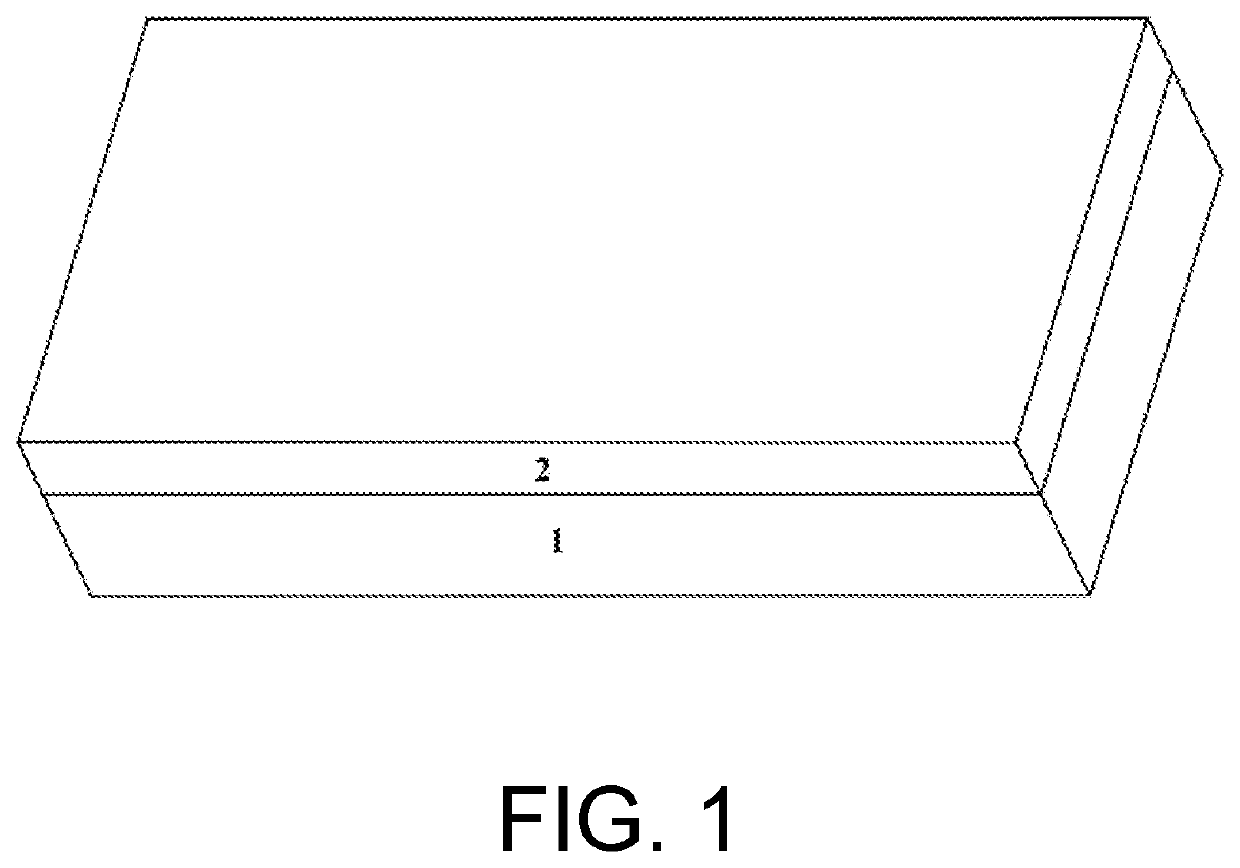

[0034]Step 1: a SiO2 dielectric layer 2 having a thickness of 100 nm is deposited on a Si substrate 1 by a CVD method, as shown in FIG. 1. Then, a ultrasonic cleaning is performed on the SiO2 dielectric layer 2 by using absolute ethanol and deionized water, where the ultrasonic power is 30 to 45 W, and the cleaning time is 3 to 5 minutes.

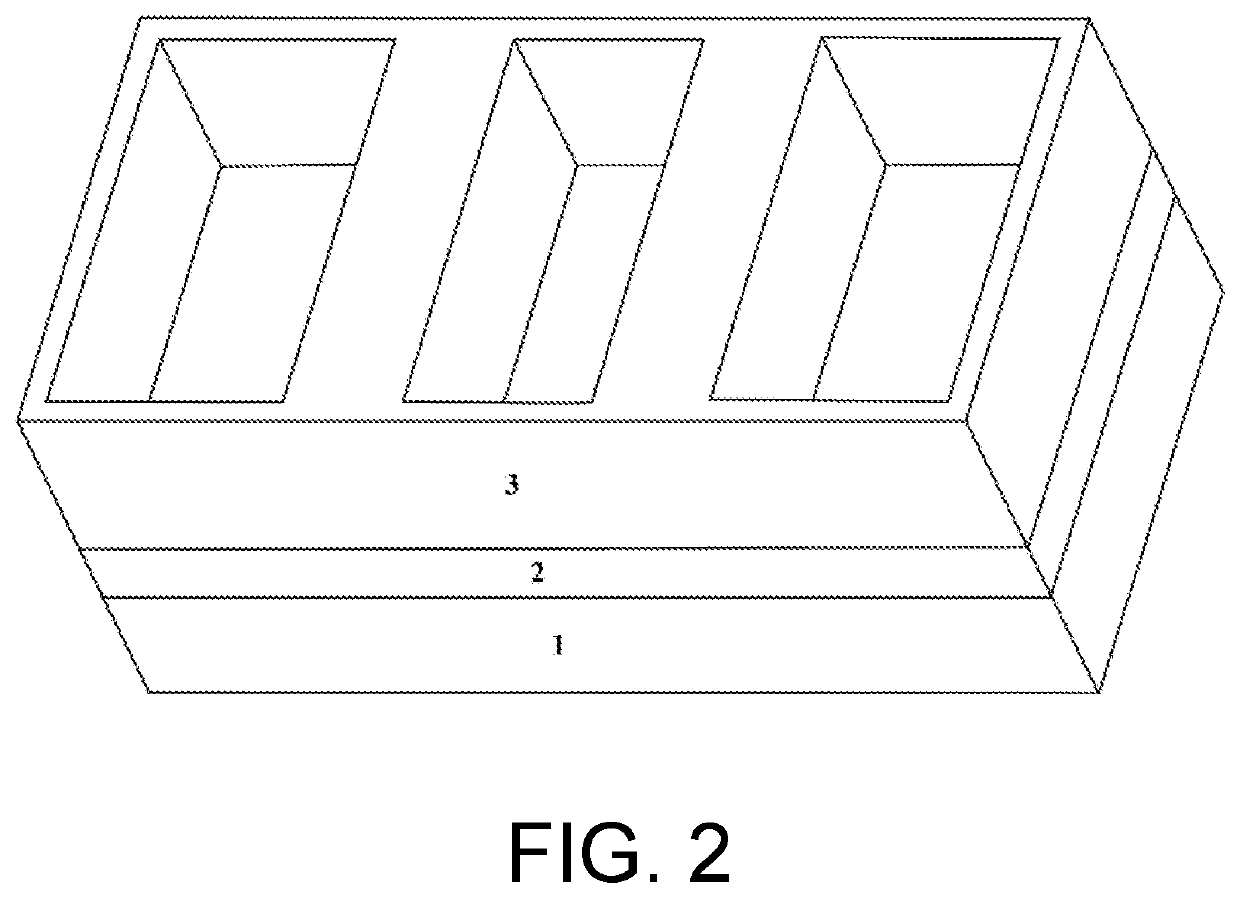

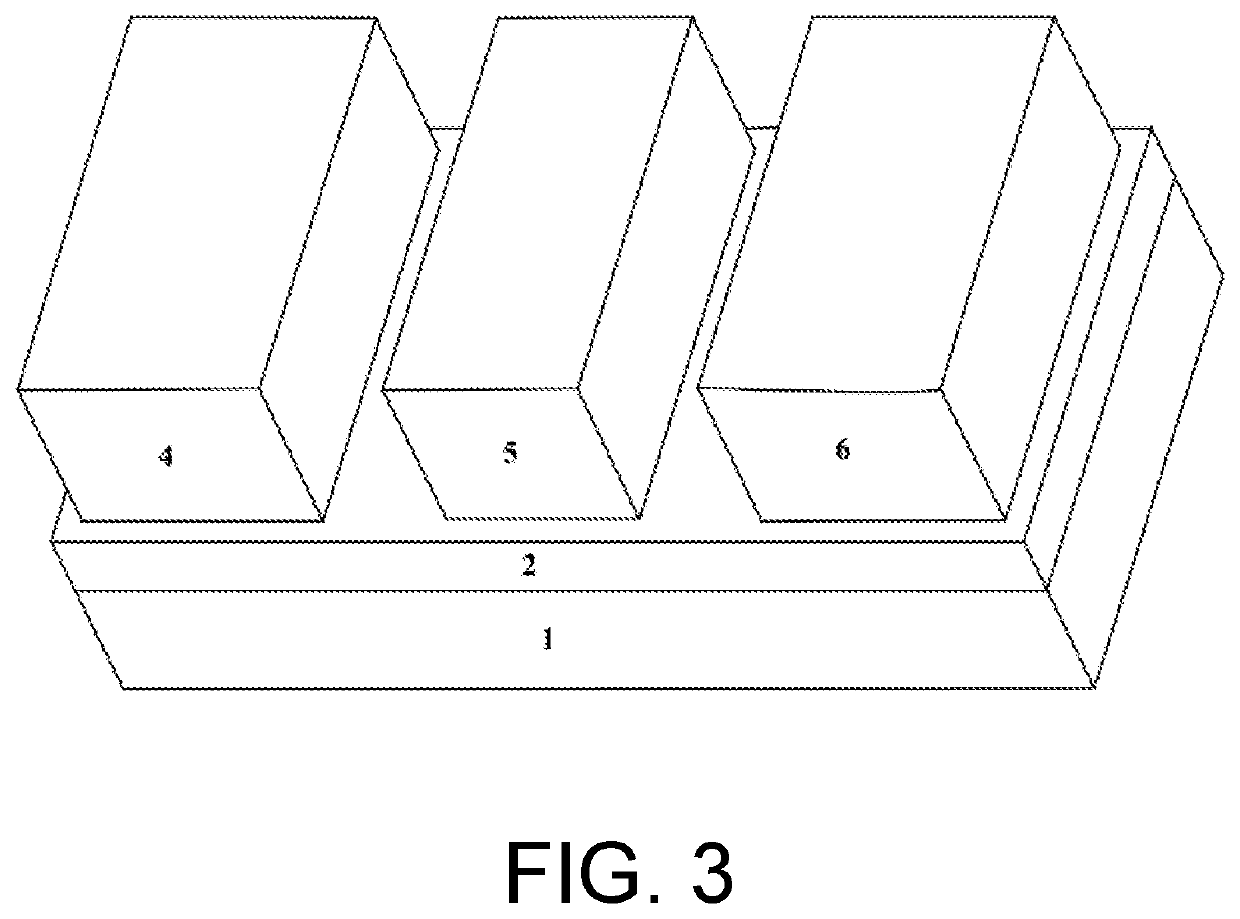

[0035]Step 2: a PPA having a thickness of 1000 nm is spin-coated on the surface of the SiO2 dielectric layer 2, where the type of the PPA is poly(phthalaldehyde), the viscosity of the PPA is 5 cp, the rotation speed of a spin-coater is 1000 to 2000 r / min, and the spin-coating time is 30 s. Three rectangular grooves are etched in the PPA by using a direct writing machine having a nano 3D structure, where for the three rectangular grooves, depths of the grooves are all 1000 nm; lengths of grooves on two sides are both 1000 nm, and widths of grooves on two sides are both 1000 nm; a length of a middle gr

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap