Method for reworking a multi-layer photoresist following an underlayer development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

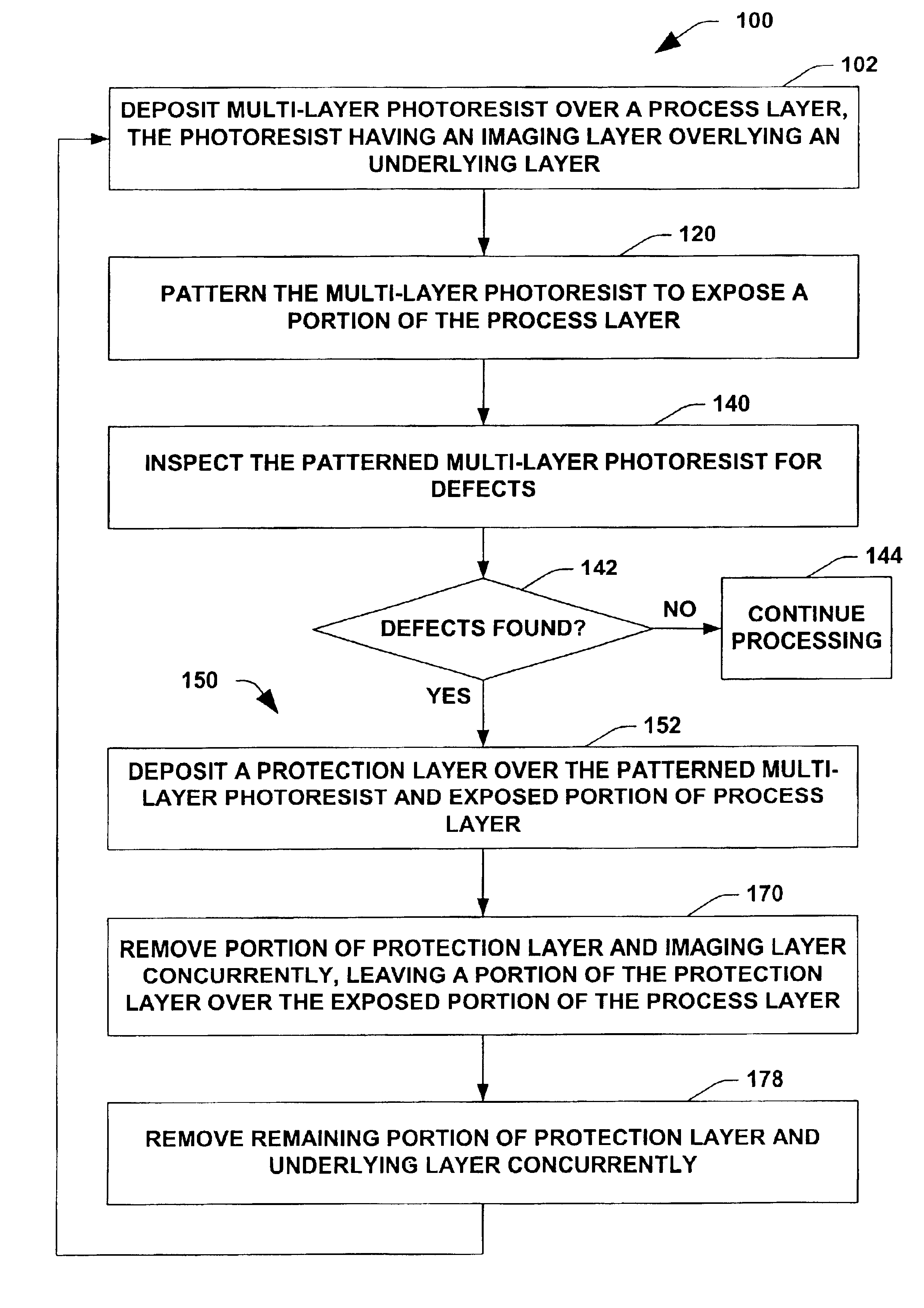

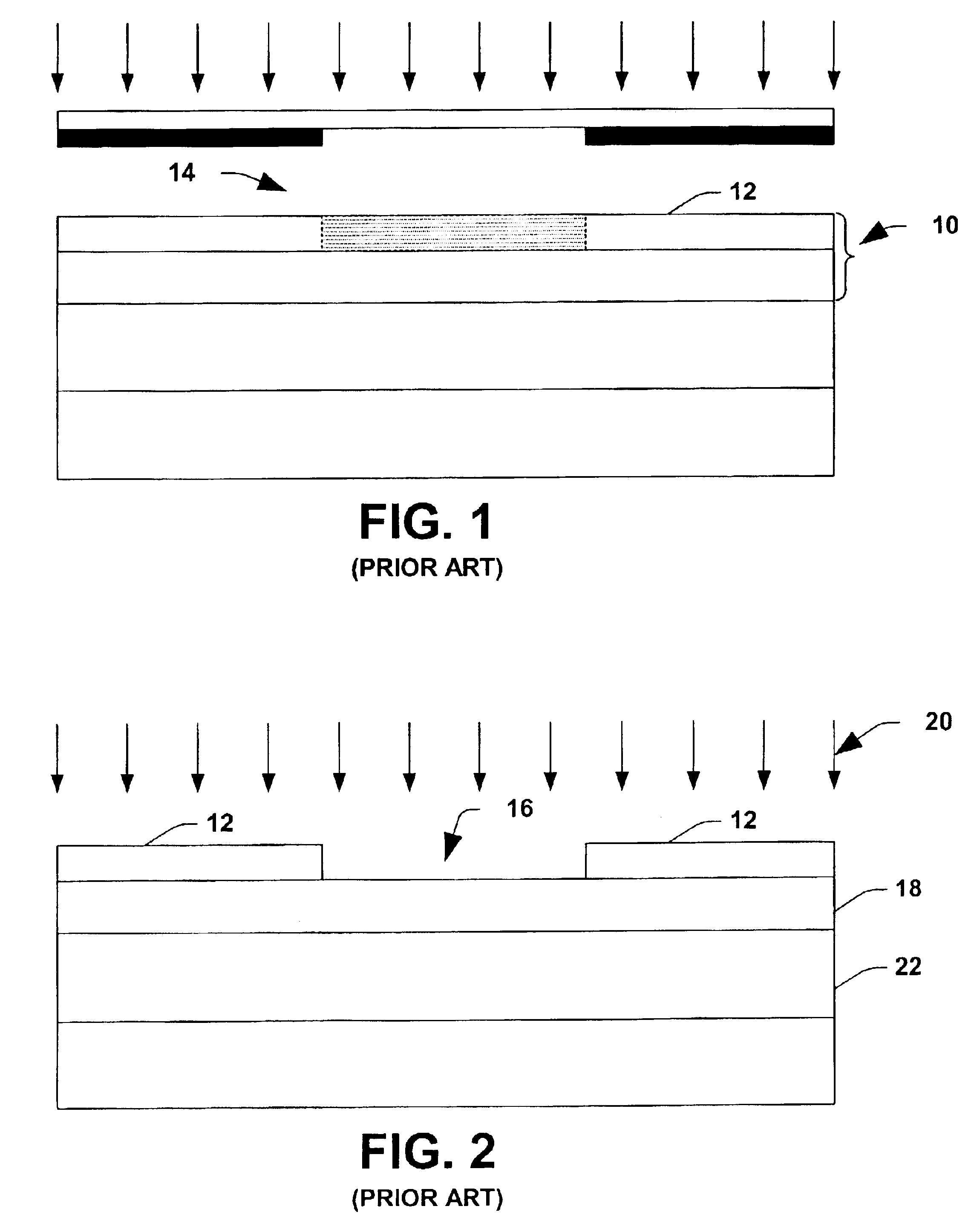

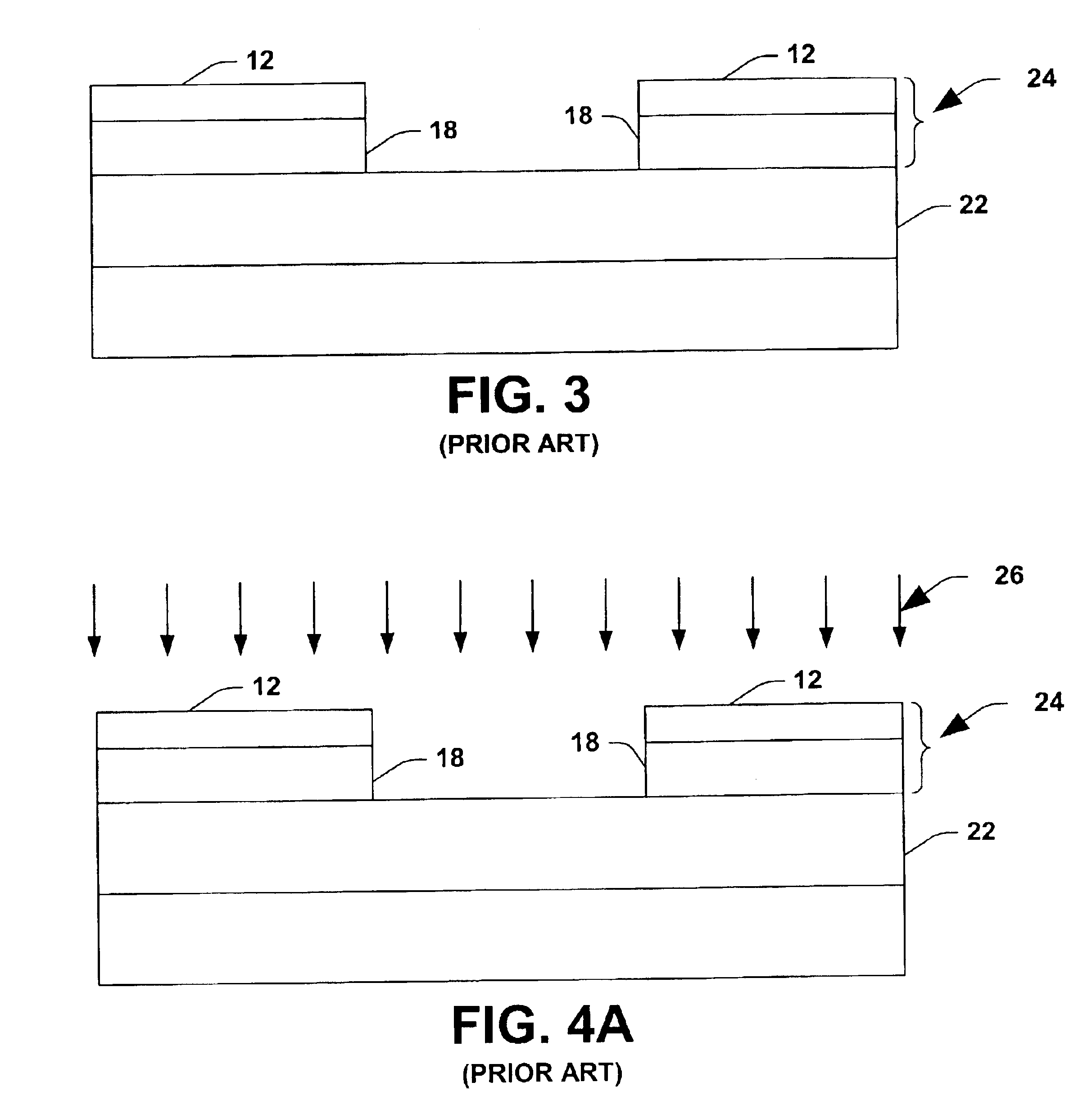

The following is a detailed description of the present invention made in conjunction with the attached Figures, wherein like reference numerals will refer to like elements throughout. The present invention is directed to a method of re-working a multi-layer photoresist. After patterning the photoresist, a portion of an underlying process layer is exposed therethrough and the resist is inspected for defects. Upon an affirmative identification of a defect, the patterned multi-layer photoresist (which comprises an underlying layer covered by an imaging layer) is covered with a protection layer, which also covers the exposed portion of the process layer. The protection layer and imaging layer are then removed in a generally concurrent fashion, after which a portion of the protection layer still resides over the exposed process layer. The underlying layer and remaining protection layer are then removed in a generally concurrent fashion. The re-work methodology of the present invention advan

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap