Brewed iced tea or non-carbonated drink dispenser with quiet operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

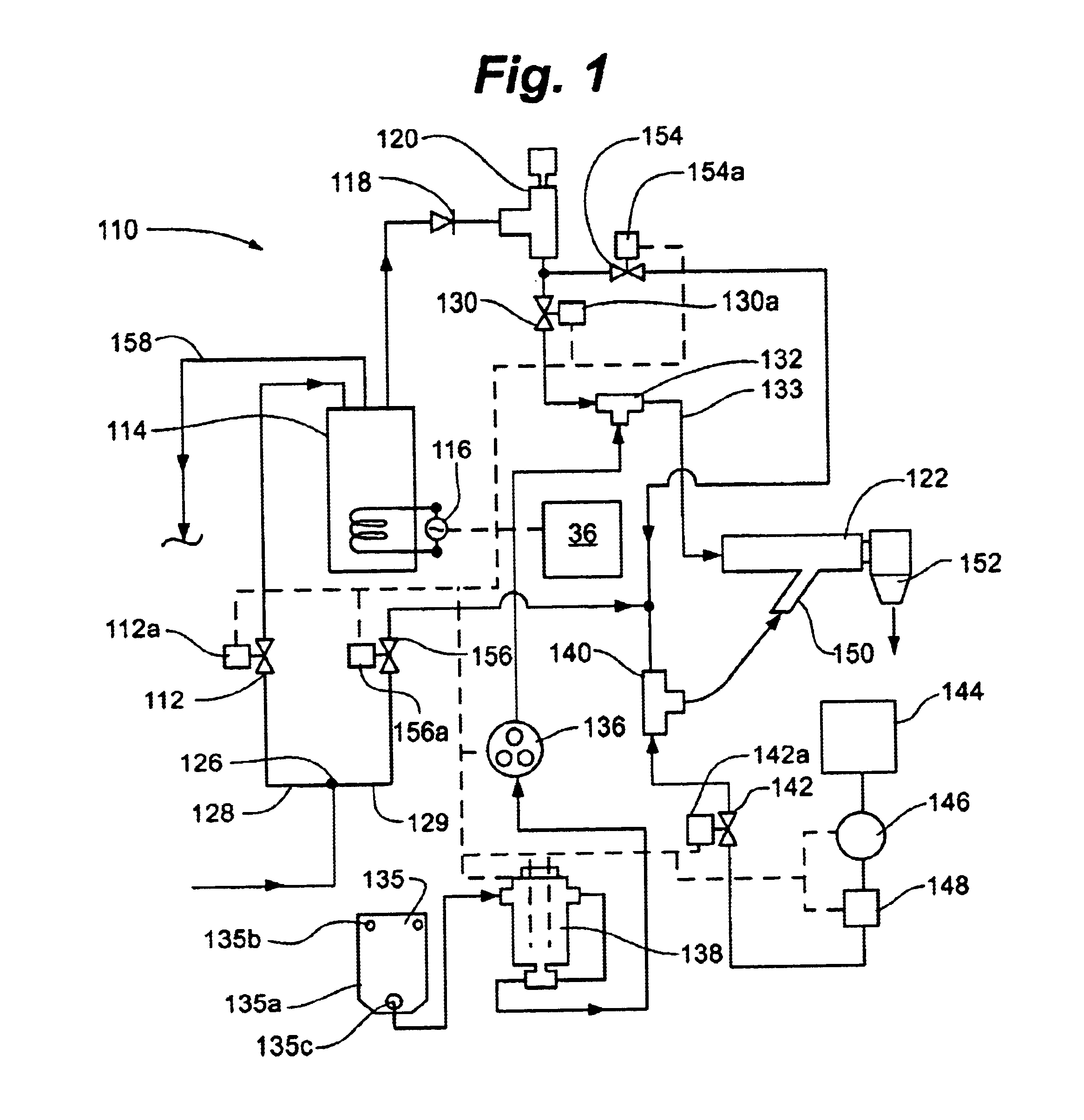

[0076]Two beverage dispensing systems may also be provided together, where one system produces sweetened tea including the liquid sweetener additive and the other system produces unsweetened tea without the additive. A dual-spigot dispenser incorporating this concept in an integral apparatus will be described later in a

[0077]The “fresh brewing” process results in a superior product in terms of taste, clarity, convenience and economy. There is also a distinct advantage with respect to controlling the unwanted growth of bacteria as compared to conventional leaf tea brewers where bacteria are not easily controlled.

[0078]Operation of the sold out sensor 138 (FIG. 1) will now be described with reference to FIG. 6. Once the concentrate 135 (FIG. 1) is depleted, i.e., the plastic bag 135a is empty or nearly empty, there is a need to provide the operator with a “sold out” indication to prevent further operation of the system. The sold out sensor ensures that only a quality finished beverage is

first embodiment

[0118]The restriction in the brew tube can be balanced by increasing or decreasing the diameter and length of the brew tube. However, changes in diameter and length of the brew tube also impact internal fluid volume, fluid velocity and residence time. A preferred way of restricting the brew tube is to crimp the tube in one or more locations so as to locally reduce the internal flow area. This way, restriction is increased without a significant reduction in internal volume that would otherwise reduce the residence time. Although not discussed specifically, such restriction is also preferable in the

[0119]In each mixing chamber assembly 522a, 522b, the pre-mixed solution is mixed with cold water. Cold water flow control solenoid valves 556a, 556b control the flow of the cold water. The cold water flows into each mixing chamber assembly 522a, 522b through a side port 550a, 550b where it is mixed with the pre-mixed solution, and the final beverage product is then dispensed through nozzle or

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap