Preparation method of graphene

A graphene and pre-reaction technology, applied in the field of graphene, can solve the problems of high local temperature, high local temperature of reactants, affecting the quality of graphene, etc., and achieve the effect of good batch consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

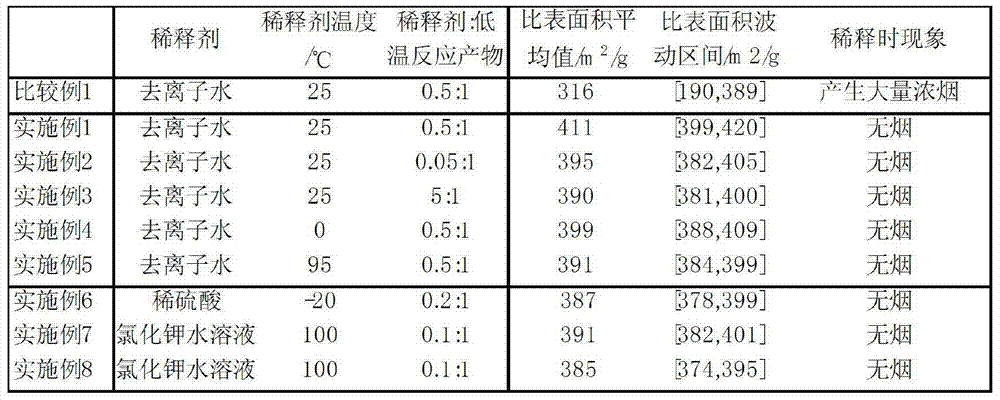

Examples

Embodiment 1

[0032] Embodiment 1, different from Comparative Example 1, this embodiment comprises the following steps:

[0033] Pre-reaction slurry configuration: according to graphite: potassium permanganate: concentrated sulfuric acid (mass concentration is 98%): the mass relation of sodium nitrate=2:5:60:1, in the reactor of 6 ℃, add the vitriol oil (mass Concentration is 98%), sodium nitrate, graphite and potassium permanganate, after being stirred uniformly, pre-reaction slurry is obtained;

[0034] Low-temperature reaction: place the pre-reaction slurry obtained above at 6°C for 4 hours to obtain a low-temperature reaction product;

[0035]Preparation of diluent: according to the mass relationship of deionized water: low temperature reaction product = 0.5:1, select deionized water at 25°C as the diluent, first inject deionized water into the reactor, and then slowly inject the low temperature reaction product into the above dilution In the agent, observe and record the phenomenon of fe

Embodiment 2

[0040] Embodiment 2, different from Embodiment 1, this embodiment includes the following steps:

[0041] Preparation of diluent: according to the mass relationship of deionized water: low temperature reaction product = 0.05:1, select deionized water at 25°C as the diluent, first inject deionized water into the reactor, and then slowly inject the low temperature reaction product into the above dilution In the agent, observe and record the phenomenon of feeding time, material temperature change and dilution process.

[0042] Others are the same as in Example 1, and will not be repeated here.

Embodiment 3

[0043] Embodiment 3, different from Embodiment 1, this embodiment includes the following steps:

[0044] Preparation of diluent: according to the mass relationship of deionized water: low temperature reaction product = 5:1, select deionized water at 25°C as the diluent, first inject deionized water into the reactor, and then slowly inject the low temperature reaction product into the above dilution In the agent, observe and record the phenomenon of feeding time, material temperature change and dilution process.

[0045] Others are the same as in Example 1, and will not be repeated here.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap