Planographic printing plate packaging structure and method for packaging planographic printing plate

a technology packaging structure, which is applied in the field of planographic printing plate packaging structure and method, can solve the problems of increasing becoming a large operational burden, and achieve the effect of reducing the operational burden of users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

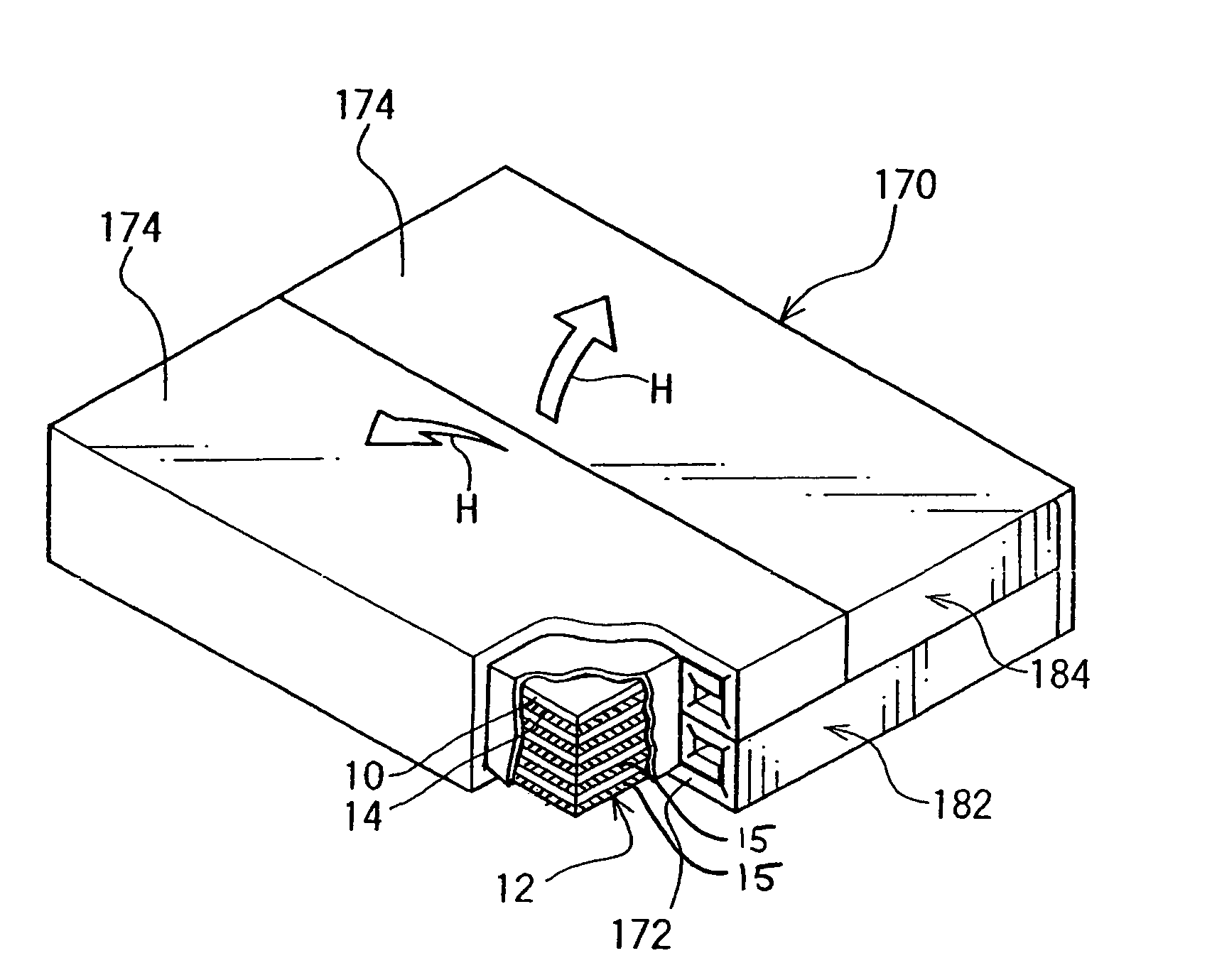

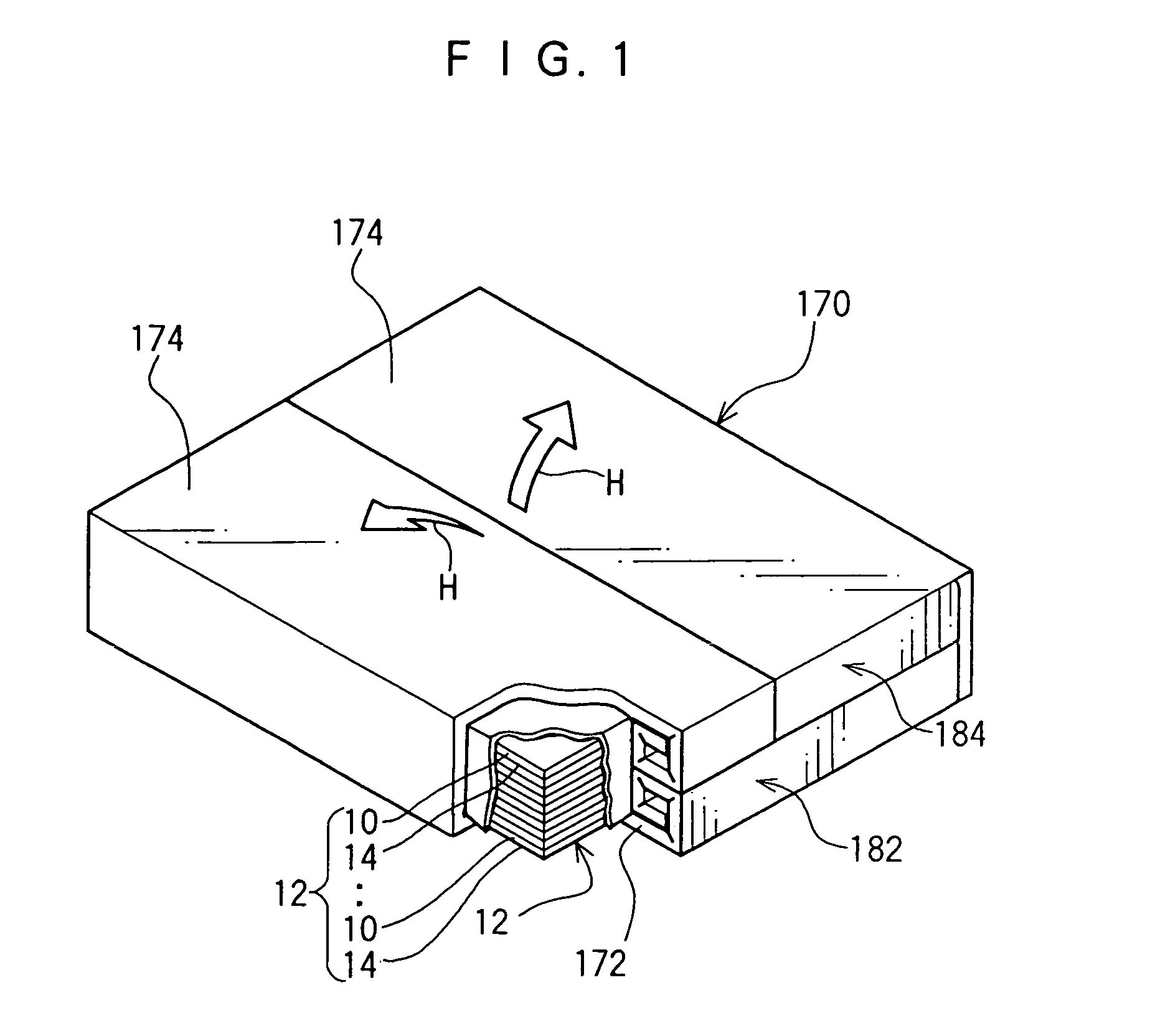

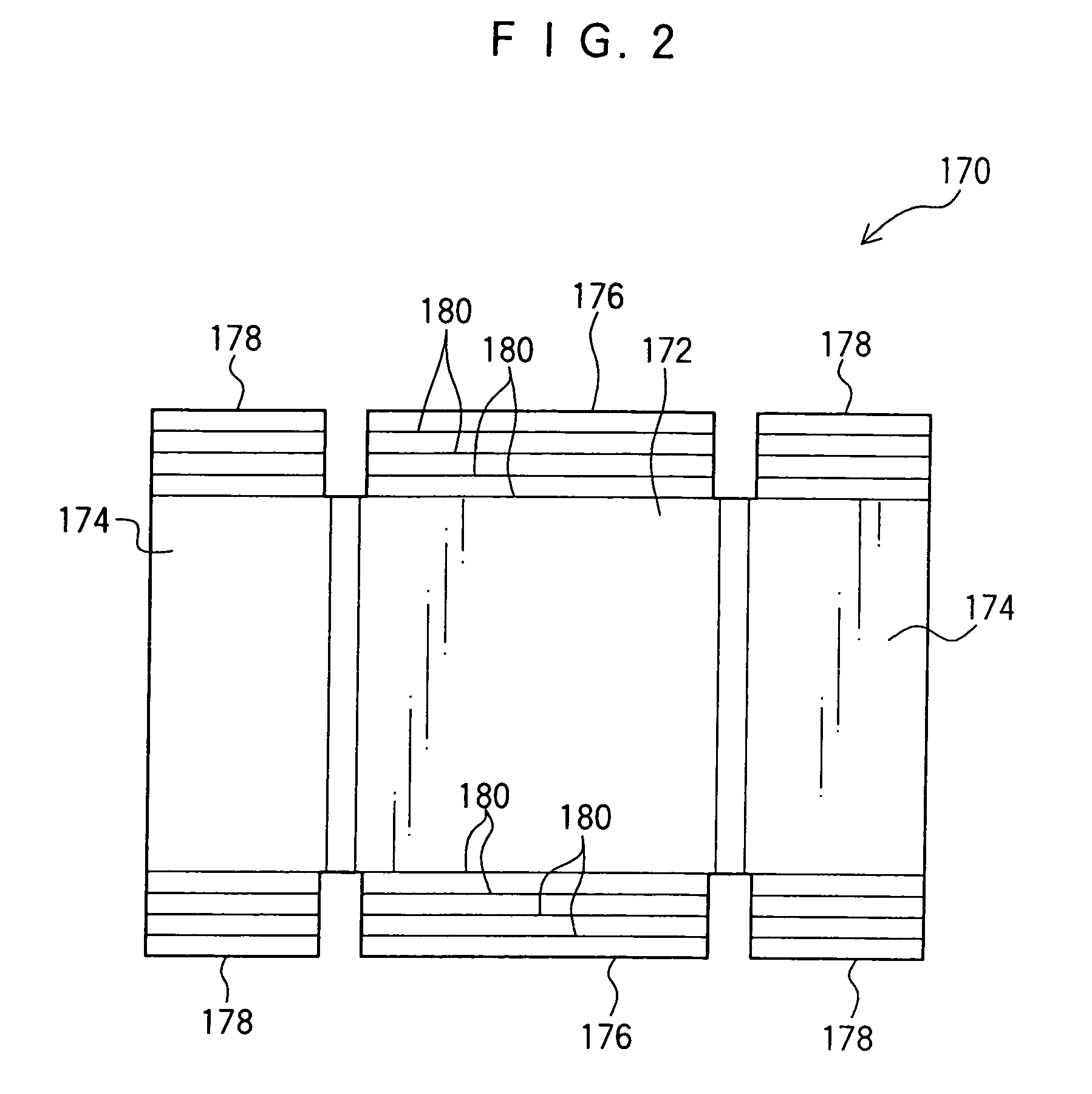

[0031]In FIG. 1, a state (of a planographic printing plate packaging structure), in which a stack 12 of planographic printing plates 10 are accommodated and packaged in a planographic printing plate packaging box 170 relating to an embodiment of the present invention, is illustrated. Also, in FIG. 2, the packaging box 170 for planographic printing plates is illustrated with an unfolded view.

[0032]The planographic printing plate 10 is formed by applying a coating film (a photosensitive layer for a photosensitive printing plate, a heat sensitive layer for a heat sensitive printing plate) onto one surface of a thin aluminum substrate which is in a form of a rectangular plate. This coating film is subjected to a plate making process including exposure, developing treatment, gum coating and the like, set into a printing machine, and coated with ink to print text, image or the like onto a paper surface. Hereinafter, as illustrated in FIG. 3, the substrate surface onto which the coating film

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap