Gas generator

a gas generator and gas technology, applied in the field of gas generators, can solve the problems of relative increase in mass or weight of gas generators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

theoretical example 1

Calculation of Gas Generant and Decomposition Material

[0021]For a given application, it is desired to produce at least 18 mols of gas output from a known gas generator, upon combustion of a predetermined amount of a gas generant. When combusted, a gas generant is known to produce 4 mols of gas per mol of gas generant. With regard to heat, each mol of gas generant is also known to liberate 18 kcal / mol upon combustion thereof. Ammonium nitrate is provided as a decomposition material. Ammonium nitrate has a heat of fusion of +18.2 kcal / mol (endothermic or heat consuming), and a heat of decomposition of about −8 kcal / mol (exothermic or heat releasing). Ammonium nitrate also liberates 3 mols of gas upon decomposition. One mol of gas generant described in this example produces 18 kcal of heat, and because the heat of fusion of ammonium nitrate requires 18 kcal of heat to bring the ammonium nitrate to its melting or fusion point (endothermic), it can be determined that one mol of gas ge

example 2

Exemplary Gas Generating Composition

[0024]An exemplary gas generant 22 includes a primary fuel, a salt of tetrazole, a metallic oxidizer, and a catalyst. An acidic and aromatic primary fuel may be provided that is selected from a tetrazole such as 5-aminotetrazole; a benzene-based fuel such as dinitrobenzoic acid, dinitrobenzamide; and nitroisophthalic acid; and mixtures thereof. The primary fuel is generally provided at about 1-50 wt % of the total composition.

[0025]The composition may also contain an aromatic or non-aromatic basic constituent that is selected from amino compounds, salts of amino compounds, alkali metal salt such as a salt of tetrazole is selected from alkali metal salts including potassium 5-aminotetrazole and sodium 5-aminotetrazole, a potassium salt of an aromatic or benzene-based salt such as potassium dinitrobenzoate, and mixtures thereof. The basic constituent is generally provided at about 1-50 wt % of the total composition.

[0026]An oxidizer is selected from me

example 3

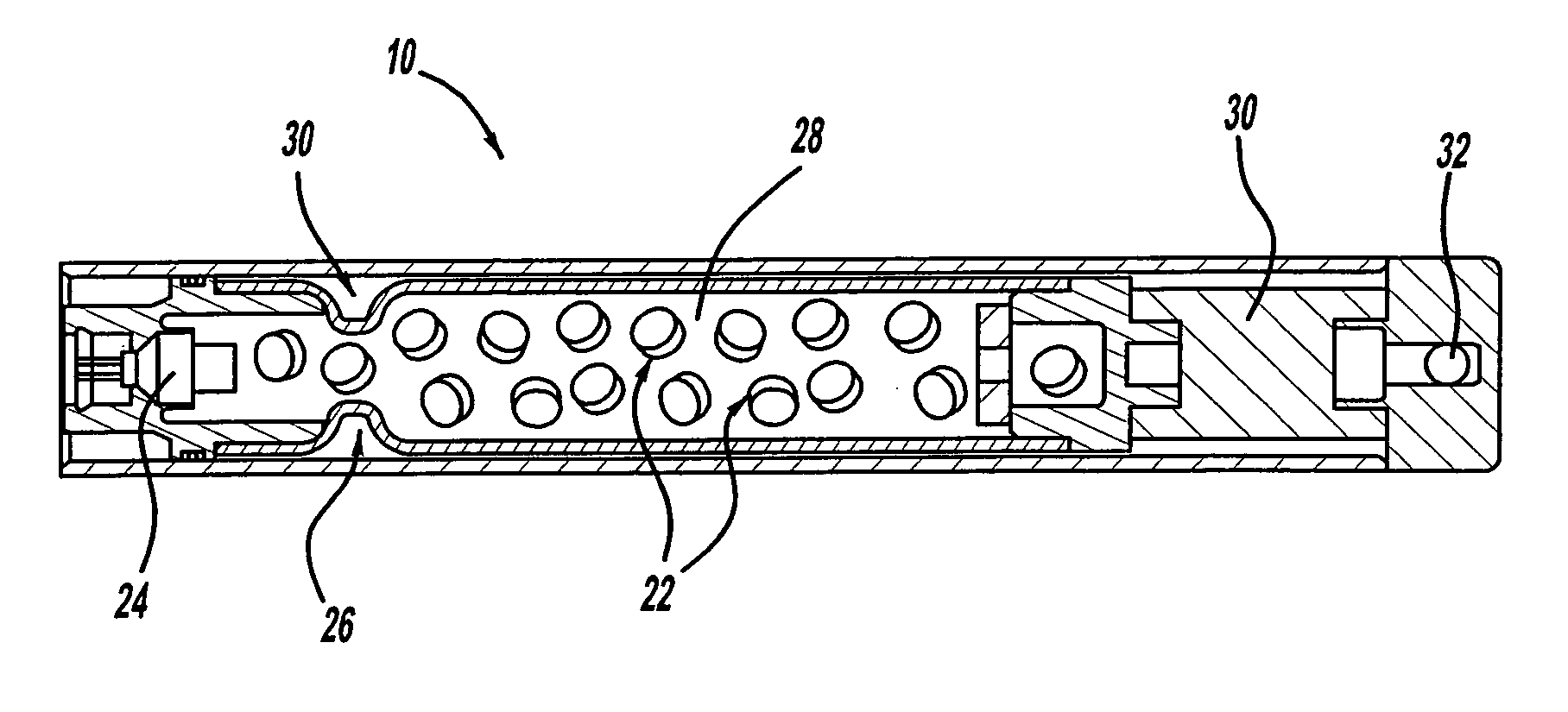

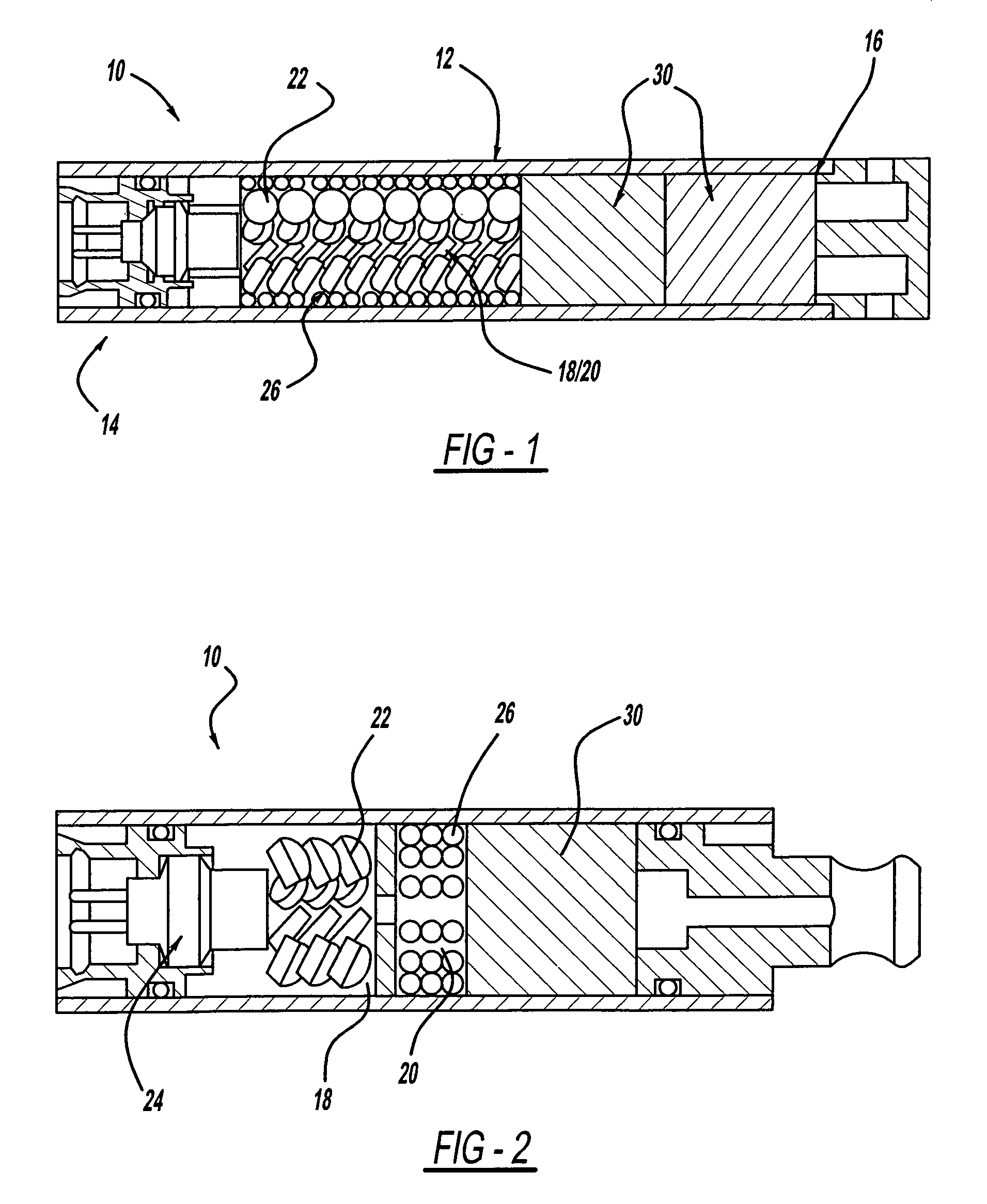

[0028]A gas generating composition 22 was formed as described in U.S. Pat. No. 6,210,505. Ammonium nitrate was provided as a decomposition material. An inflator 10 constructed as shown in FIG. 1 was charged with 25 grams of the gas generating composition and with 8 grams of the ammonium nitrate by simply scattering and dispersing the ammonium nitrate about the gas generant bed, thereby commingling the composition 22 and the ammonium nitrate in a heterogeneous manner. The inflator 10 was actuated within a 60 L tank and pressure curves over time were evaluated. The chamber pressure peaked at 64.6 MPa in 8.0 ms, with a time to first gas measured to be 3.2 ms. The tank pressure at 10 ms was measured to be 137.3 kPa. The tank pressure at 20 ms. was measured to be 244.8 kPa. At 45.3 ms, the tank pressure was measured to be 313.8 kPa.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap