Flange shear connection for precast concrete structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

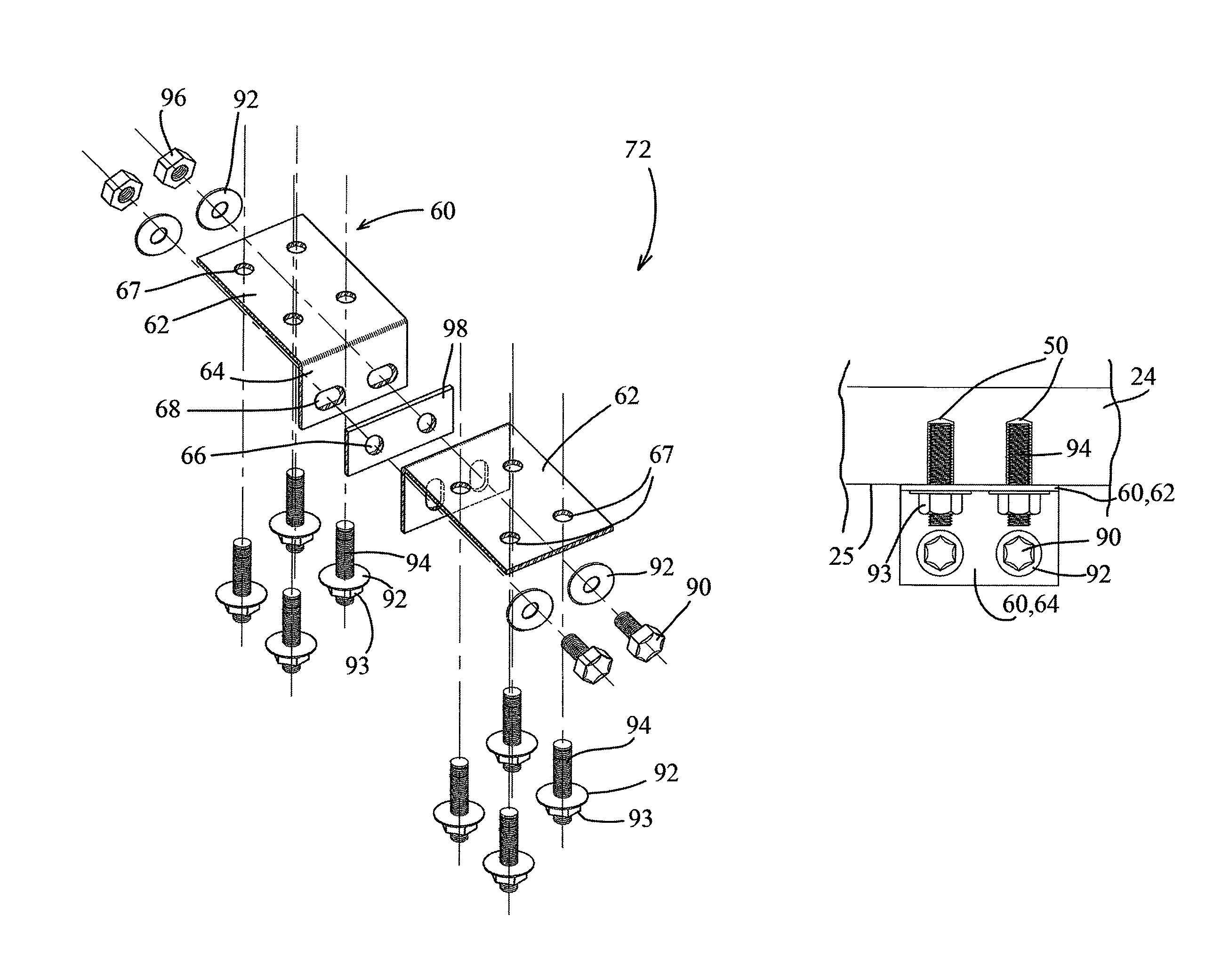

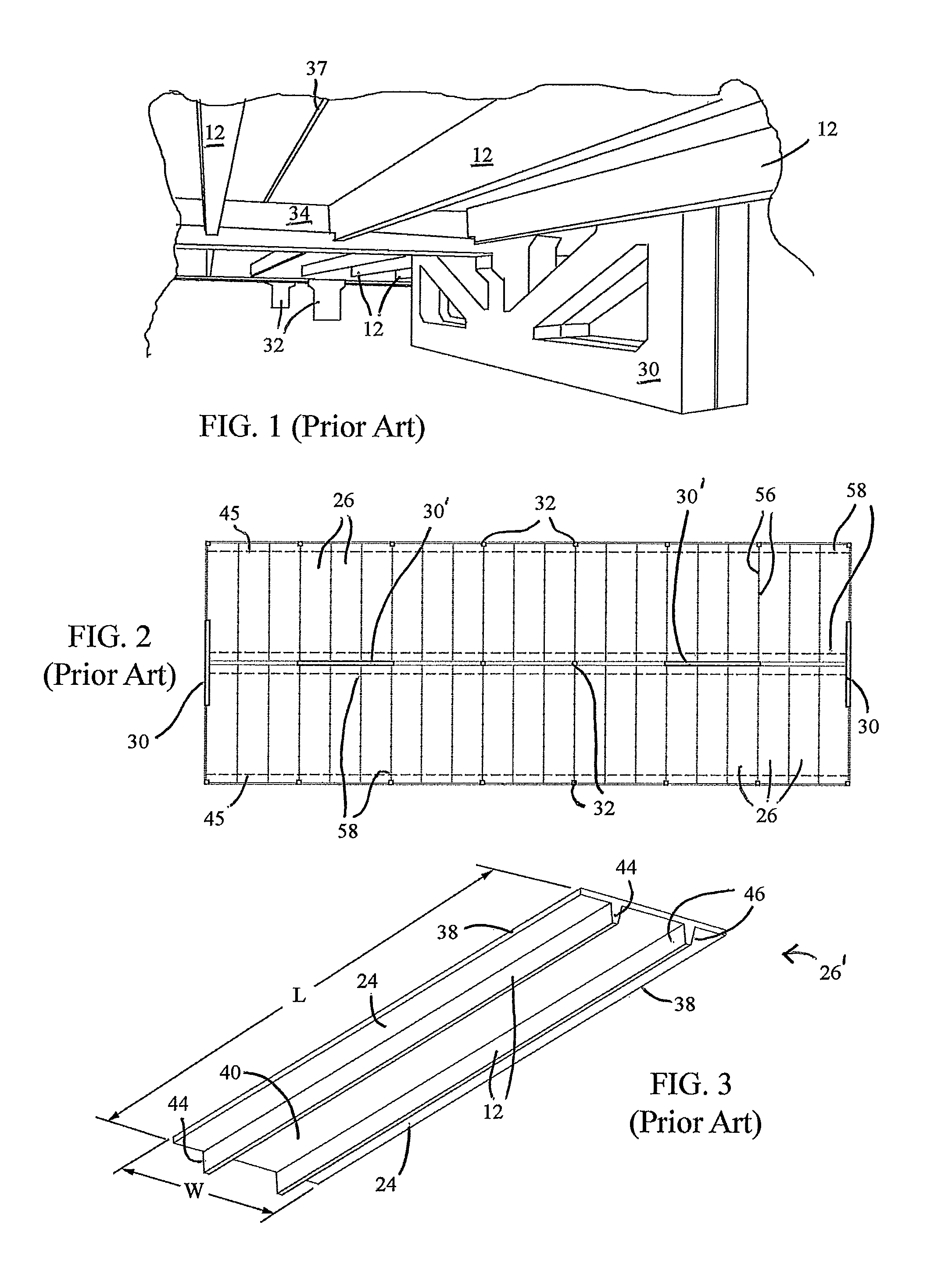

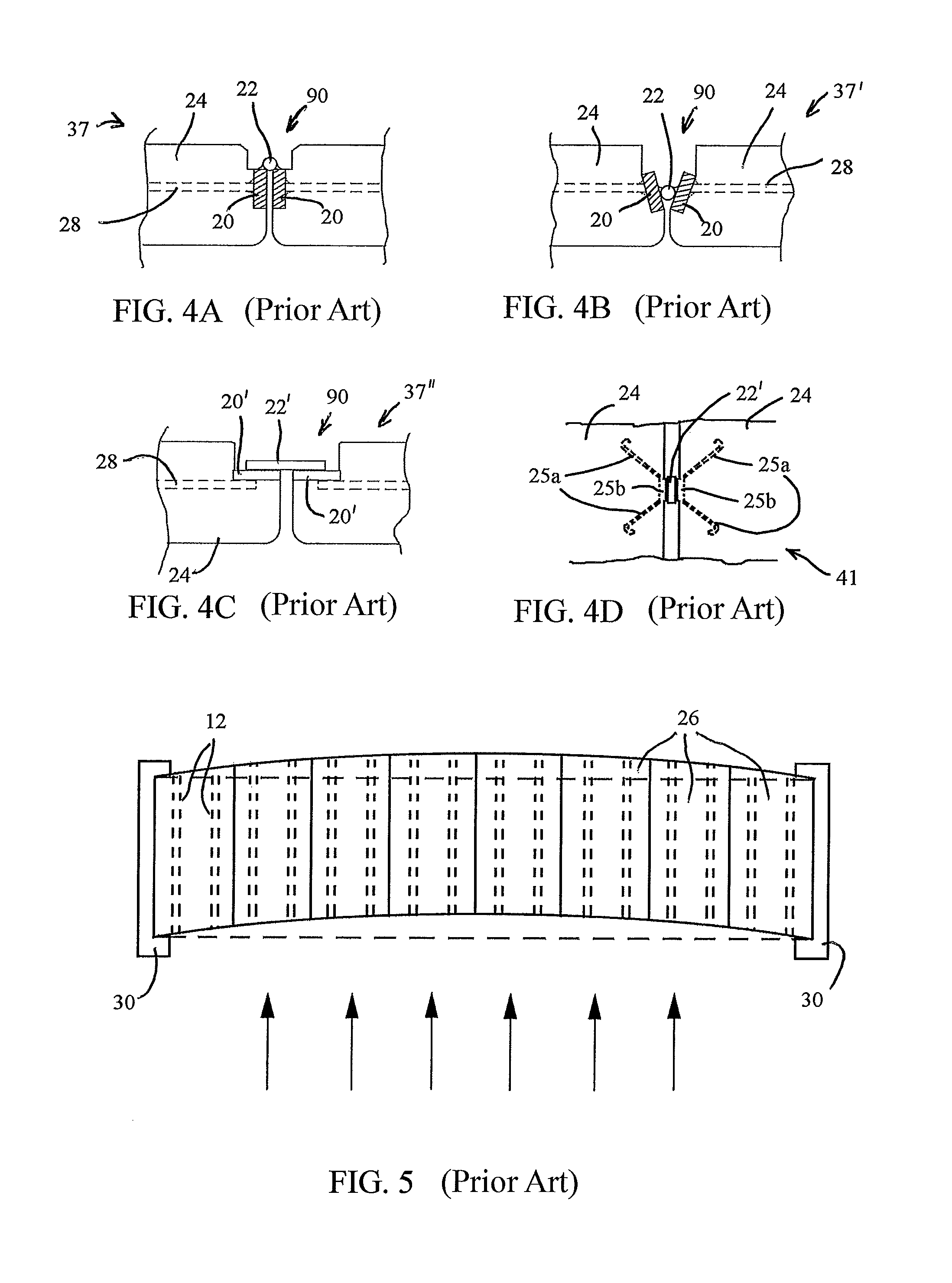

[0058]In describing the preferred embodiment of the present invention, reference will be made herein to FIGS. 6-24 of the drawings in which like numerals refer to like features of the invention.

[0059]The present invention is an apparatus and a system for creating, replacing, restoring or reinforcing flange connections of adjacent precast concrete structures such as a double tee beam. The system includes providing flexible shear connections along the flanges of adjacent concrete structures. The shear connection is for securing the tee beams from shear forces which shift one beam vertically from the adjacent beam due to gravity loads or longitudinally due to lateral forces such as seismic and wind loads.

[0060]The concrete structure 8 shown in the top elevational view of FIG. 6 includes flexible shear connections 56 along adjacent flanges 24 of precast concrete members 26. The concrete structure 8 is preferably a parking garage and includes at least one diaphragm 6a, 6b which comprises a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap