Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Asphalt concrete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Asphalt concrete (commonly called asphalt, blacktop, or pavement in North America, and tarmac, bitumen macadam, or rolled asphalt in the United Kingdom and the Republic of Ireland) is a composite material commonly used to surface roads, parking lots, airports, as well as the core of embankment dams. Asphalt mixtures have been used in pavement construction since the beginning of the twentieth century. It consists of mineral aggregate bound together with asphalt, laid in layers, and compacted. The process was refined and enhanced by Belgian inventor and U.S. immigrant Edward De Smedt.

Asphalt regenerating agent with modification function and preparation method thereof

ActiveCN104788975AIncrease elasticityImprove temperature stabilityBuilding insulationsSocial benefitsEngineering

Owner:WUHAN UNIV OF TECH

Regeneration process of waste asphalt micro powder

The invention provides a regeneration process of waste asphalt micro powder. The process comprises the following steps: milling an asphalt concrete pavement, wherein the milling thickness of the first layer is 1-5cm, and the milling thickness of the second layer is 5-10cm; sieving the milling material of the first layer, and mixing the obtained particles with the particle sizes of 10-31.5mm with emulsified asphalt, hydroisomerized residue oil and the like for regeneration; and crushing the milling material of the second layer, sieving and collecting particles with the particle sizes of 10-20mm, and mixing the obtained particles with fine particles of the milling material of the first layer, residue oil and the like for regeneration. According to the method, the waste asphalt in the milling material can be fully recycled in relatively low cost, and meanwhile, road paving requirements can be well met.

Owner:BEIJING AURORA ENVIRONMENTAL PROTECTION SCITECH INST

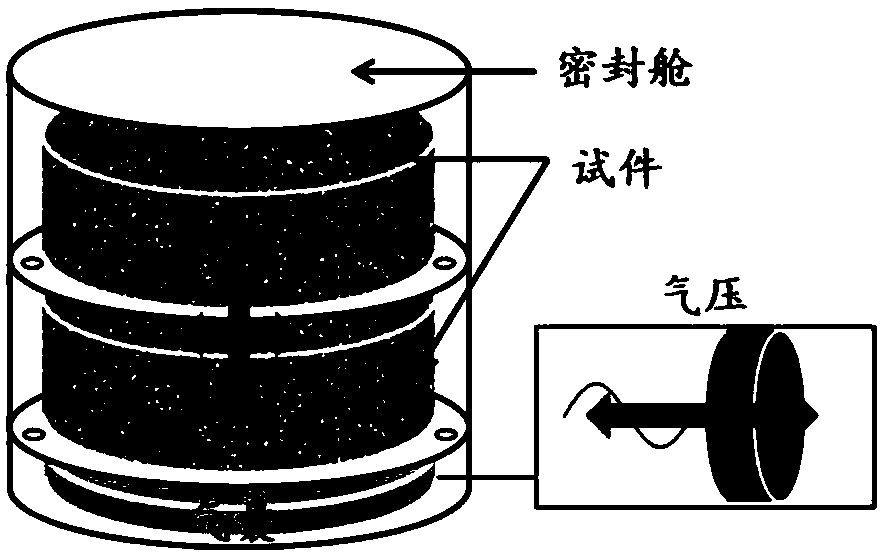

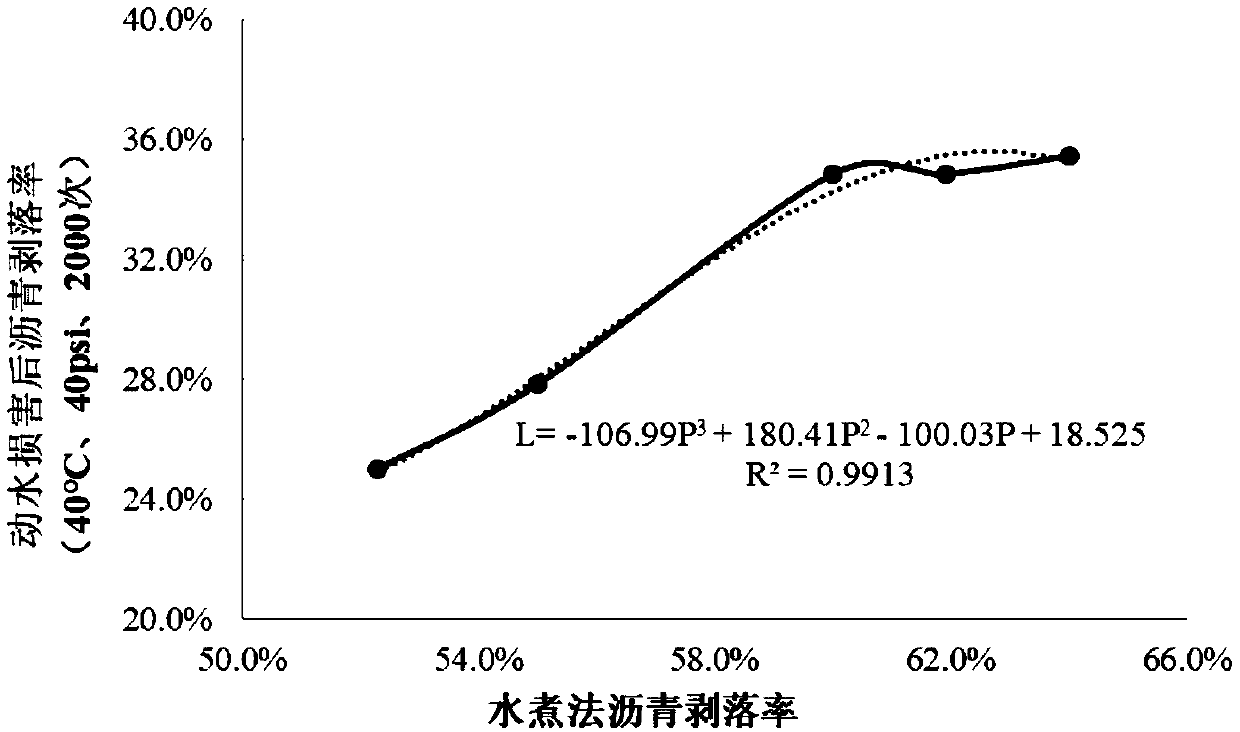

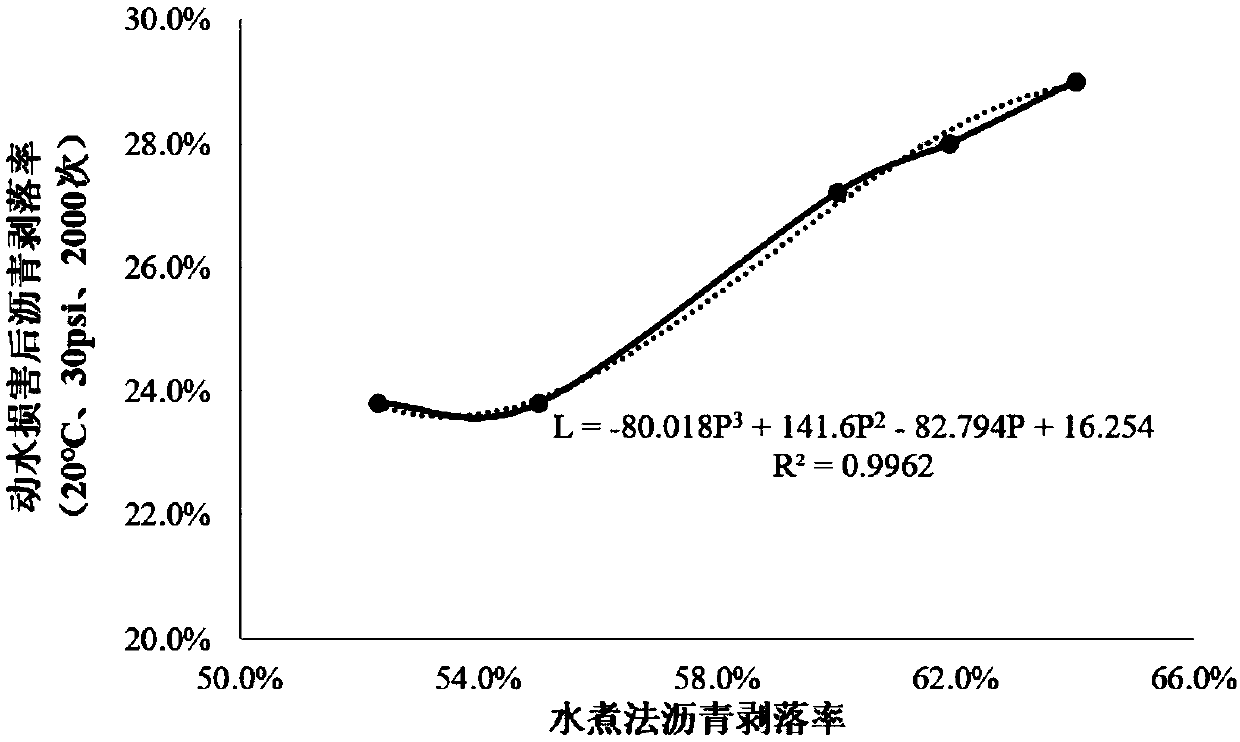

Calculation method for asphalt and aggregate stripping rates of asphalt pavement

ActiveCN109596456ARealisticEasy to operateWeighing by removing componentPreparing sample for investigationPavement engineeringRoad surface

Owner:WUHAN UNIV OF TECH

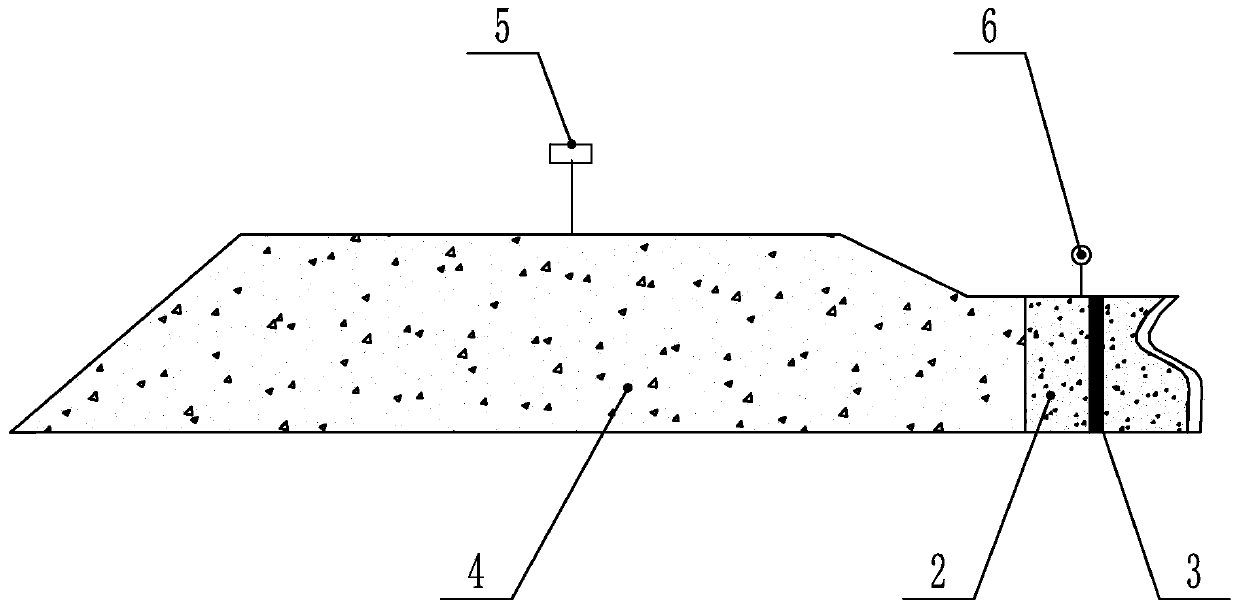

High-bearing-capacity pavement structure and paving construction method

PendingCN114575212AGuaranteed filling densityAchieving uniformity of distributionPaving reinforcementsIn situ pavingsScreedCrushed stone

The high-bearing-capacity pavement structure comprises a graded broken stone layer, a mortar layer is laid on the graded broken stone layer, a bonding layer is laid on the mortar layer, and an asphalt concrete overlay layer is laid on the bonding layer; a reinforcement cage is arranged in the bonding layer, outer ribs are arranged on the upper side and the lower side of the reinforcement cage, and the outer ribs extend into the mortar layer and the asphalt concrete overlay layer. The paving construction method of the high-bearing-capacity pavement structure comprises the following steps: 1) leveling a site and erecting a template; (2) paving a large-particle-size gravel layer; (3) paving a small-particle-size gravel layer; (4) rolling to form a graded broken stone layer; the construction method comprises the following steps of (1) paving cement mortar to form a gravel grouting layer, (2) mounting a reinforcement cage, (3) paving a bonding layer, (4) paving a bonding layer, and (5) paving cement mortar to form a gravel grouting layer, (6) mounting a reinforcement cage, (7) paving a mortar layer, (8) paving a bonding layer, and (9) paving an asphalt concrete overlay layer.By adopting the structure and the method, the pavement structure is optimized, the stability between layers of pavements is enhanced, the slippage risk of the pavement is reduced, and reliable environmental conditions are provided for normal operation of roads.

Owner:CHINA RAILWAY BEIJING ENG GRP CO LTD

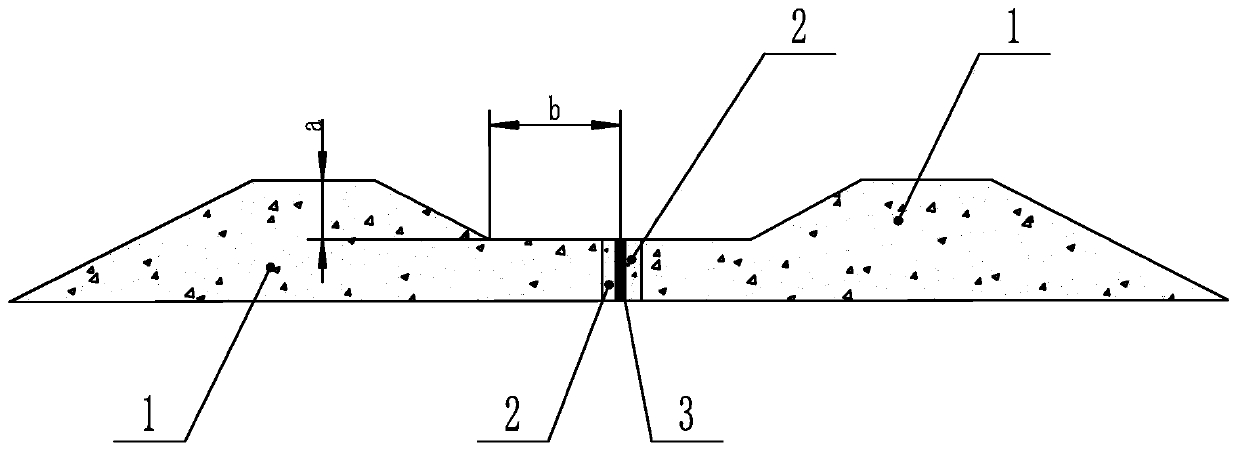

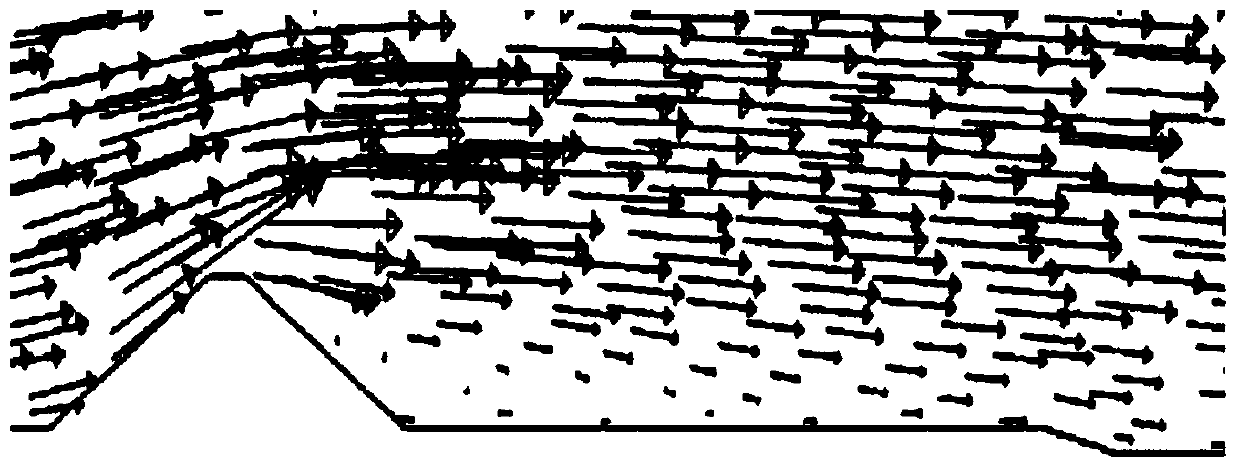

Asphalt concrete construction method for preventing wind and sand by utilizing filling height difference between dam body and core wall

InactiveCN111364301AConvenient for continuous constructionAchieve windproof effectRoadwaysProtective constructionStructural engineeringAsphalt concrete

Owner:XINJIANG AGRI UNIV

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap