Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Block structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

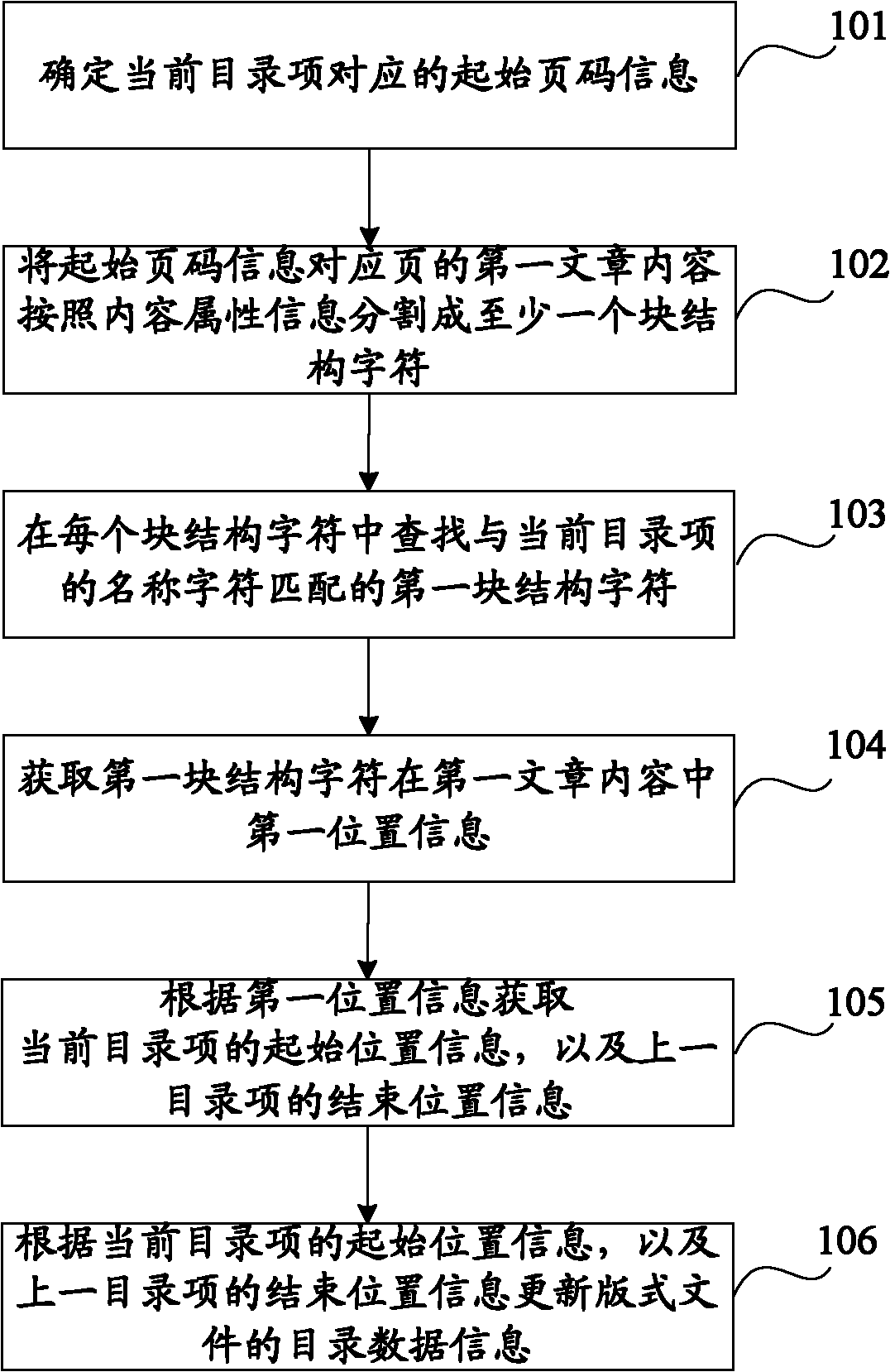

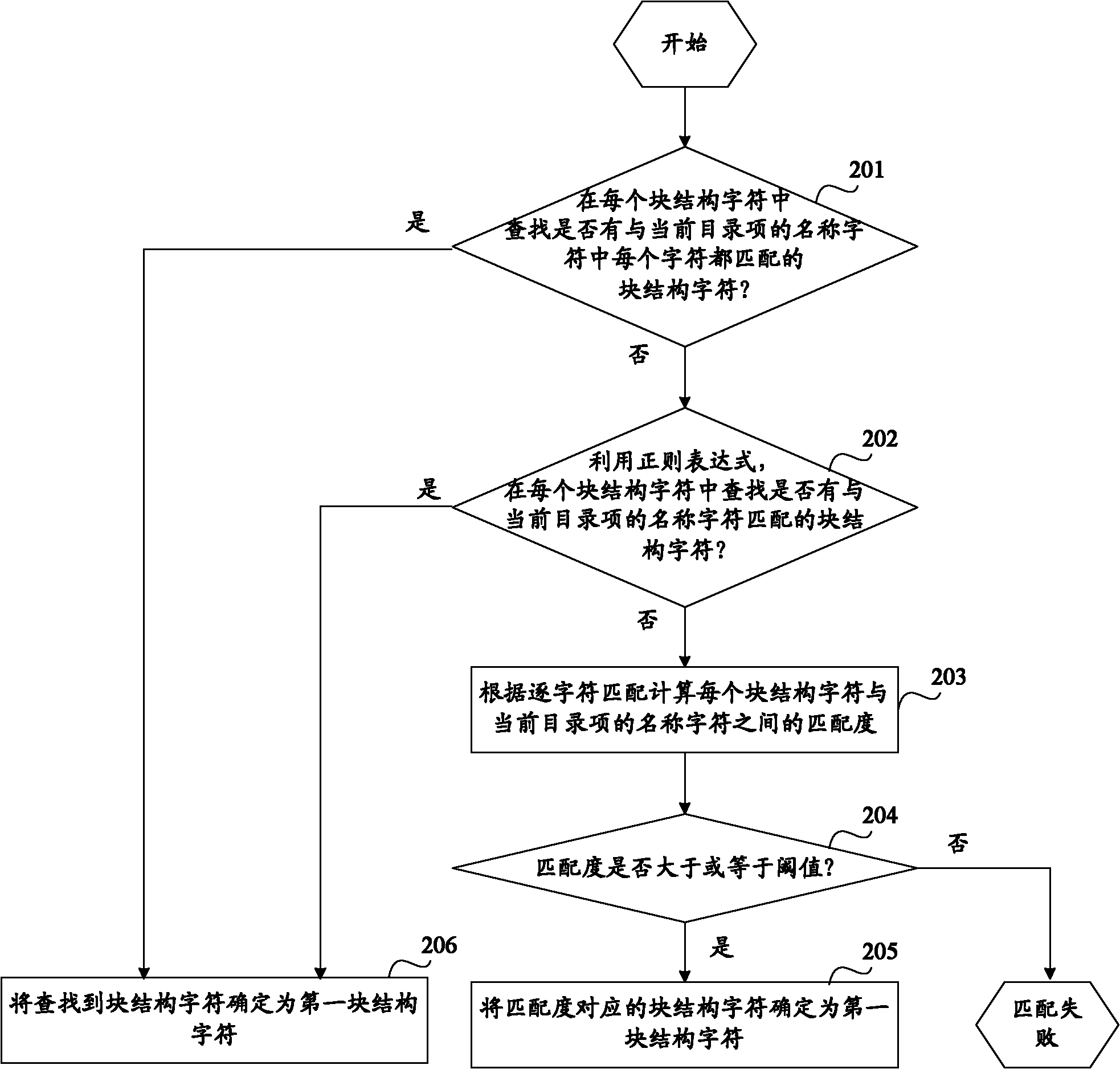

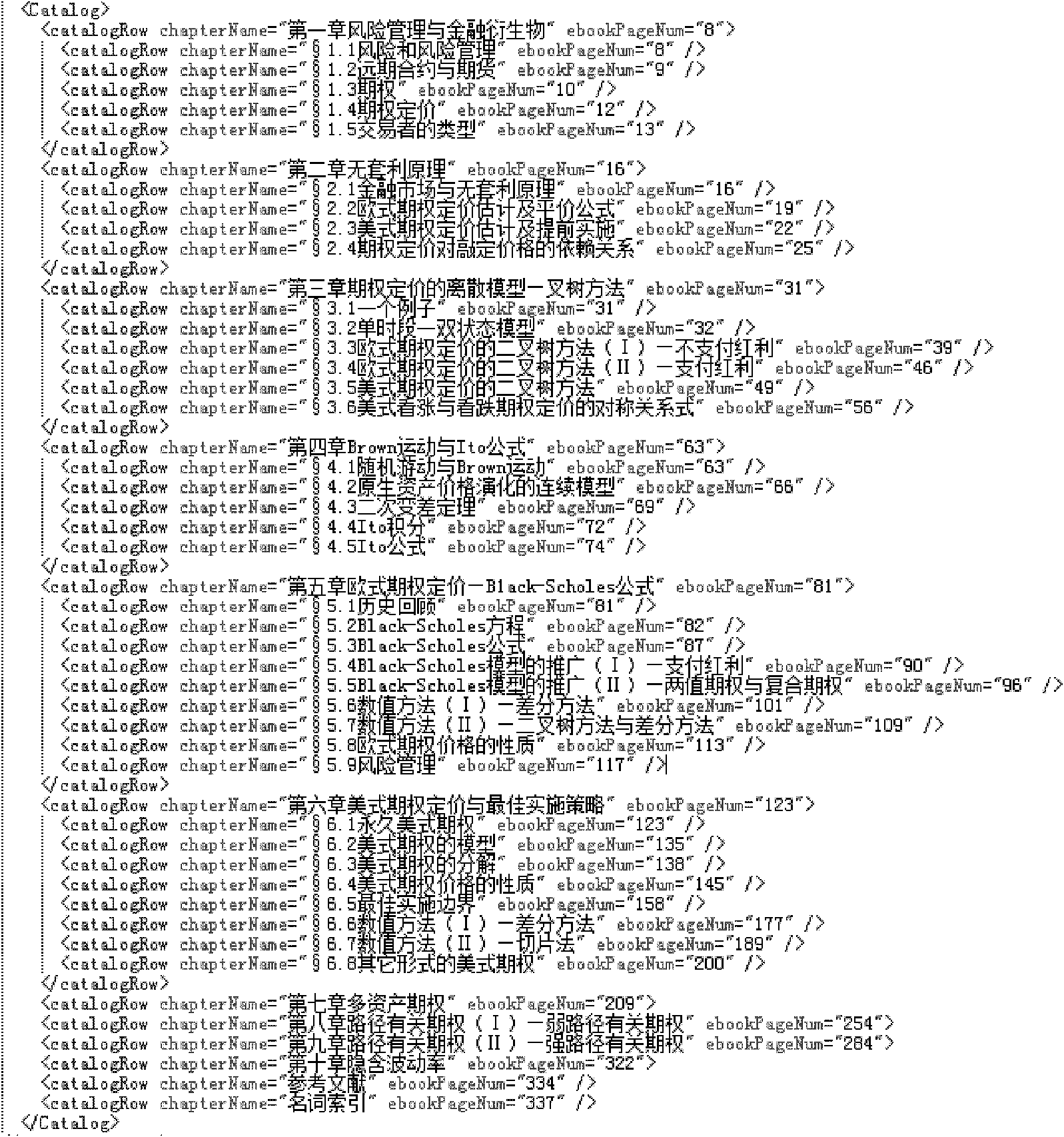

Method and device for obtaining structuring information in layout files

ActiveCN103164388ASpeed up structuringNatural language data processingComplex mathematical operationsBlock structureComputer science

Owner:NEW FOUNDER HLDG DEV LLC +1

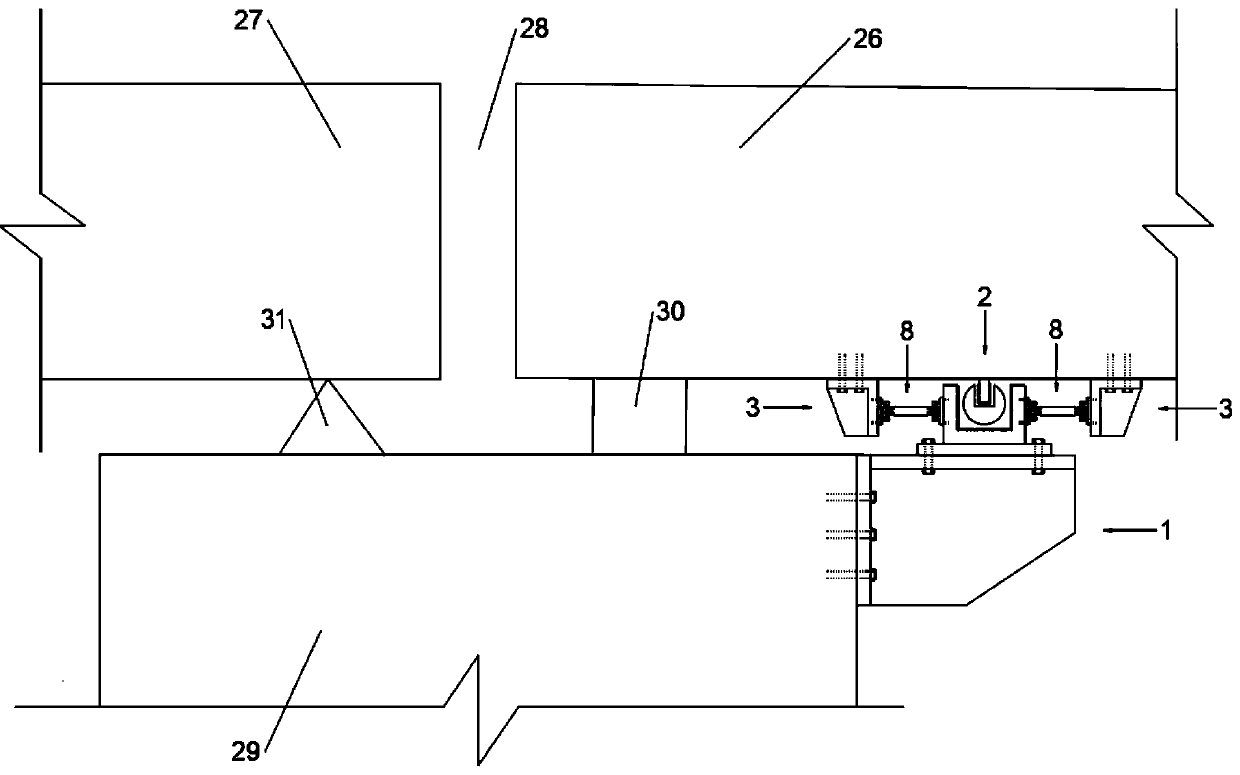

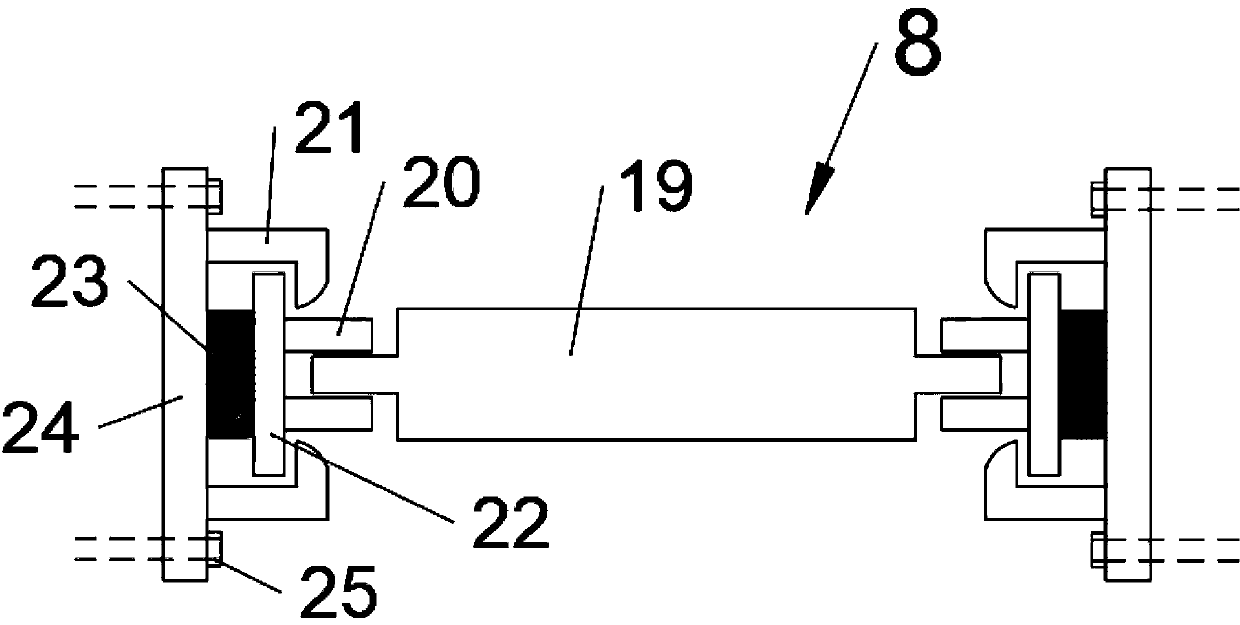

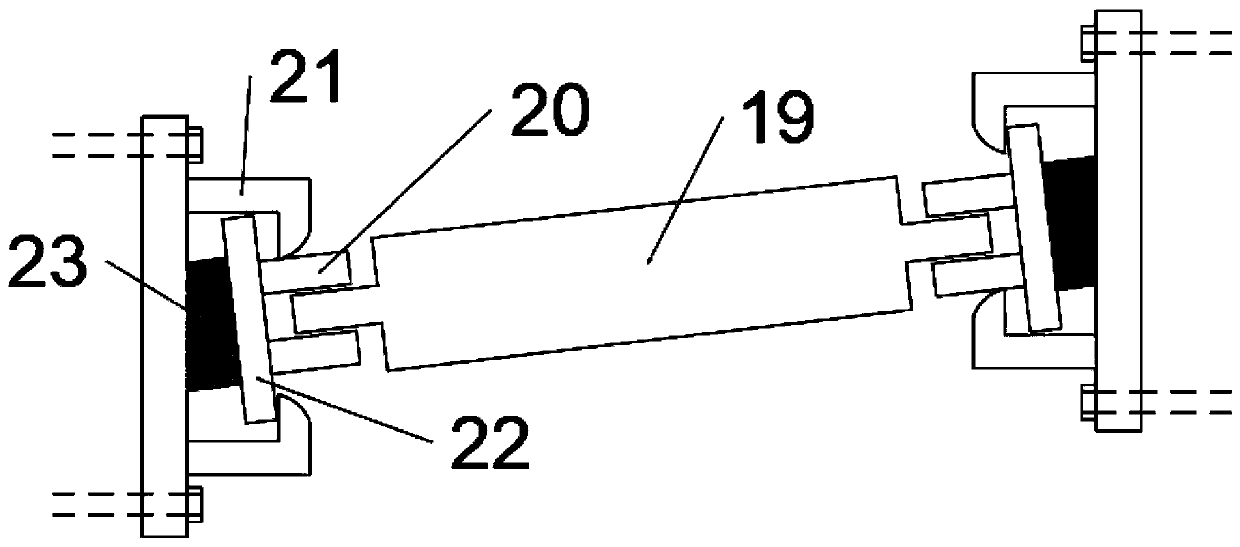

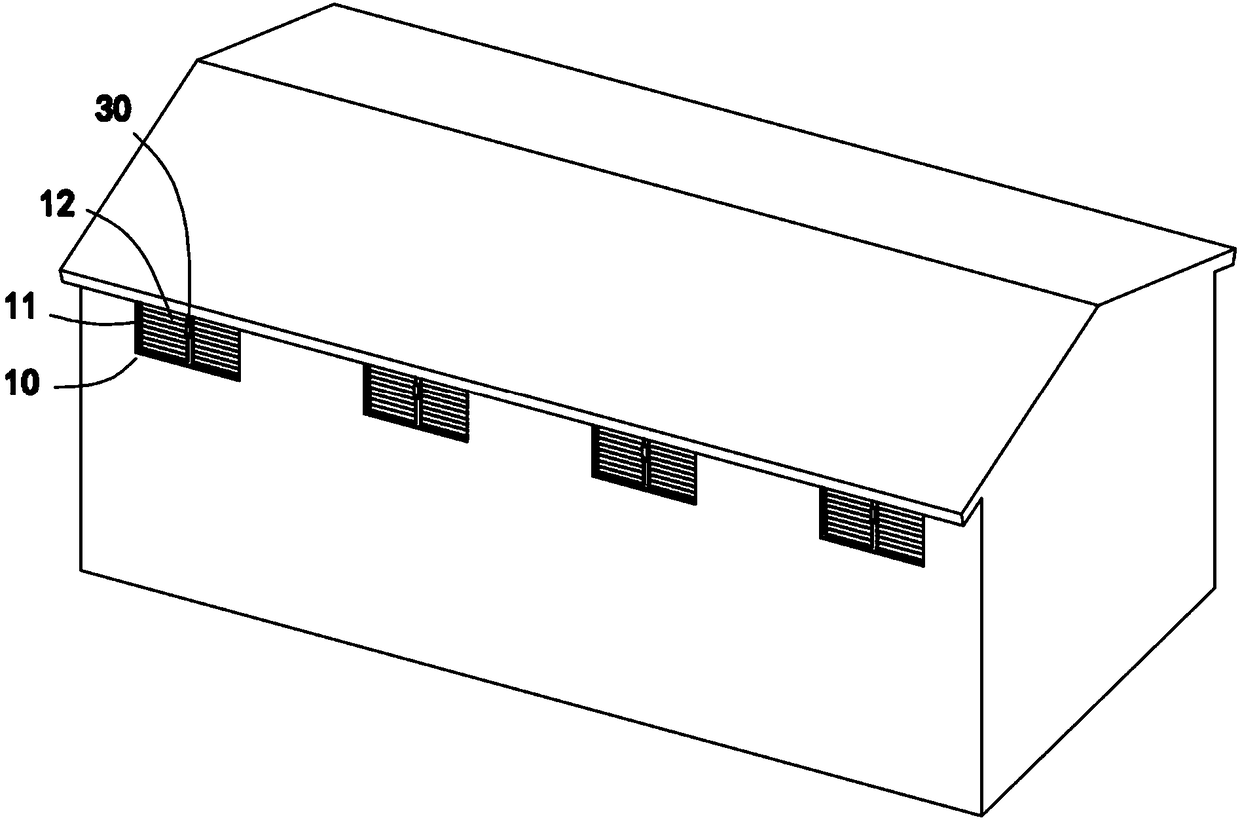

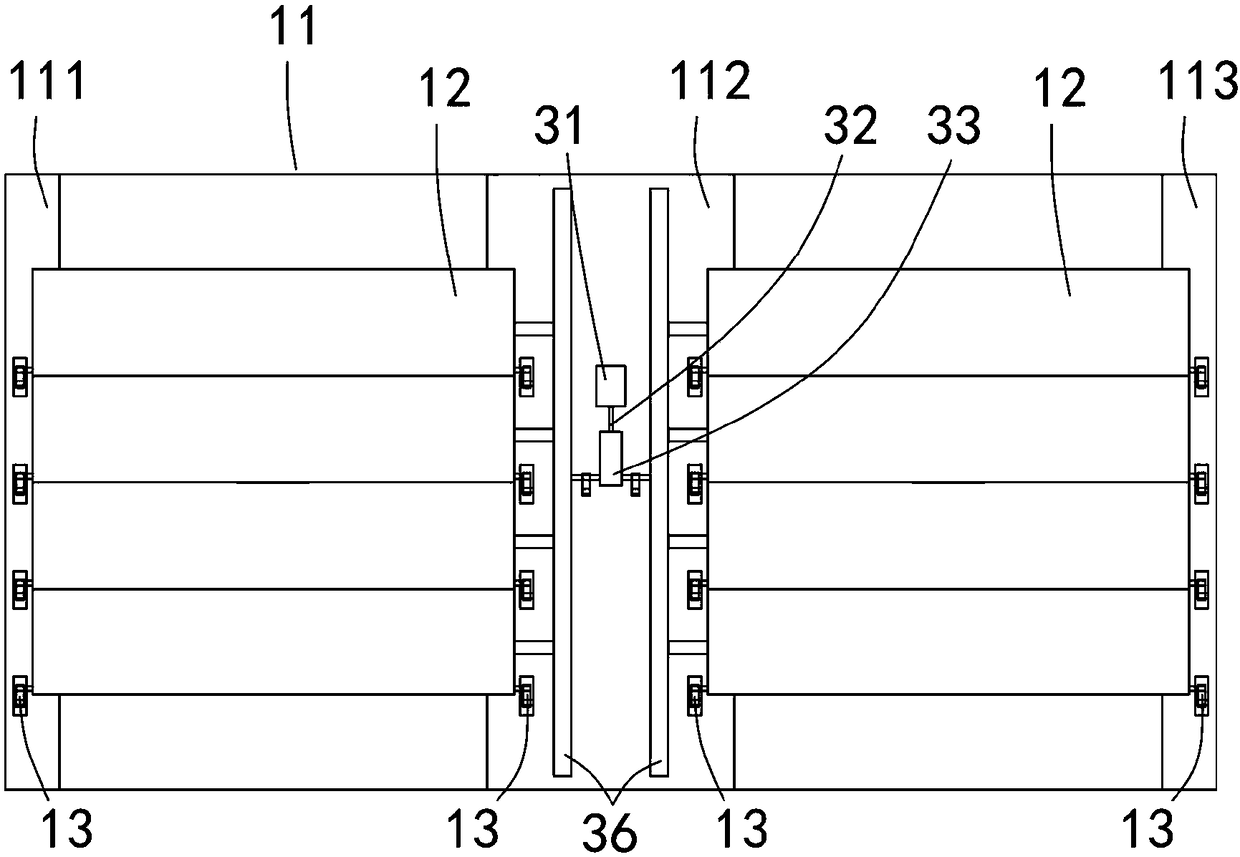

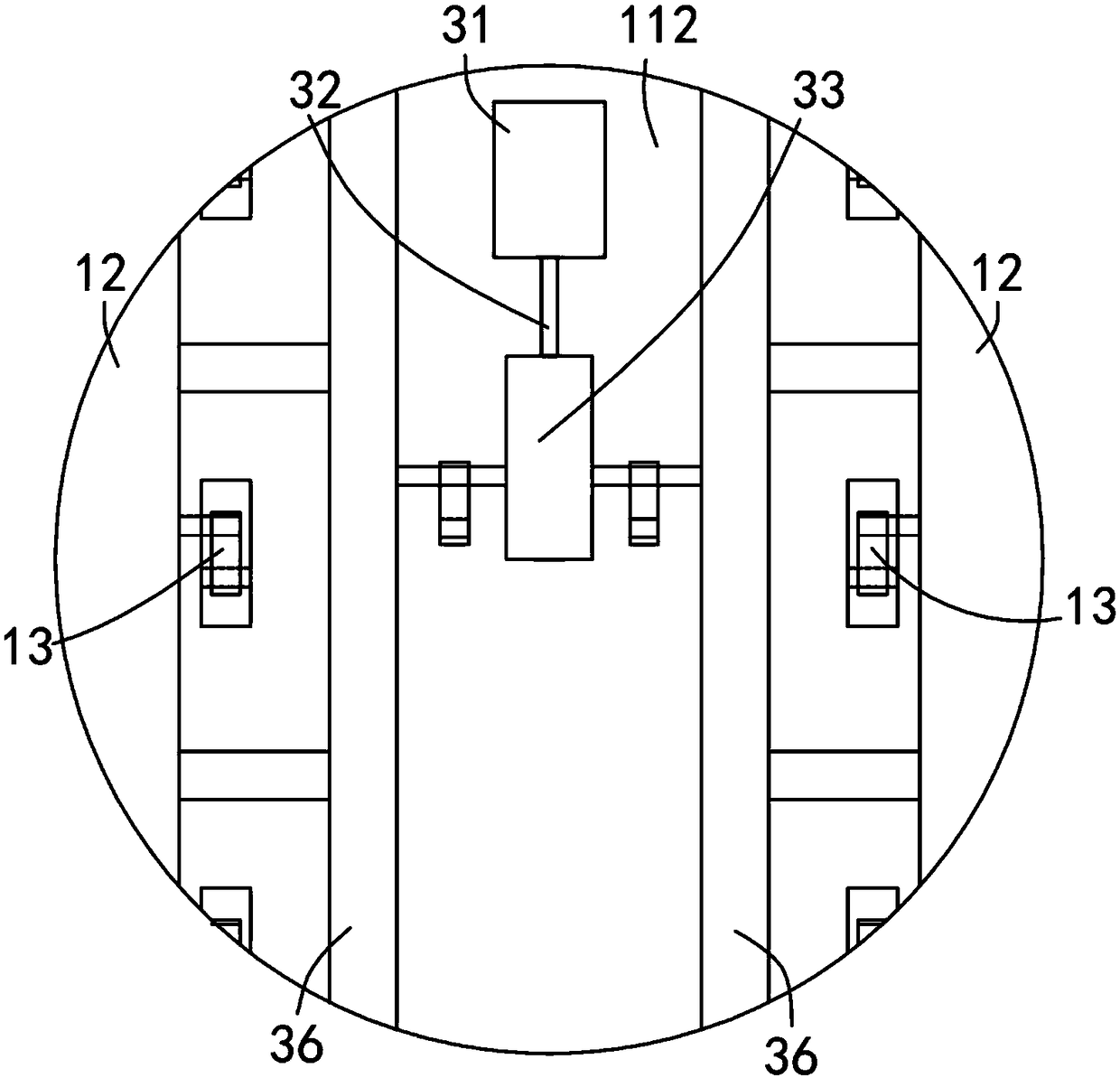

Multi-damping buffer energy dissipation type bridge anti-seismic check block structure

PendingCN111364348AAvoid damageWith multiple damping joint actionBridge structural detailsArchitectural engineeringDamper

Owner:NANCHANG UNIV

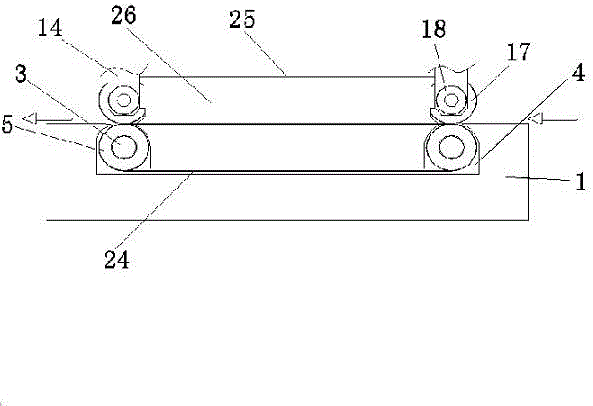

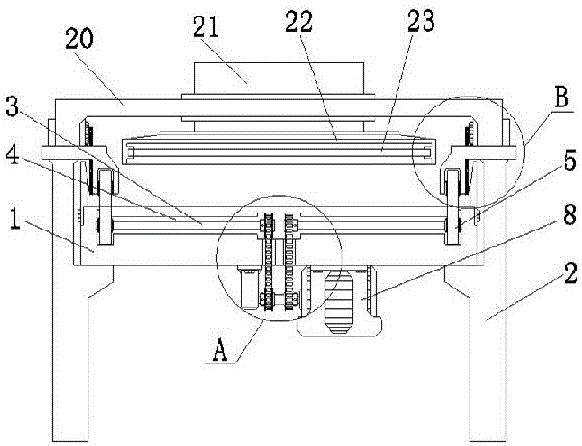

Transmission and drying integrated mechanism for production of enamel stained paper

InactiveCN106567280AEffective limit fixedTo achieve the effect of drying integrationPhysical paper treatmentEngineeringBlock structure

Owner:唐山市开平区永欣花纸技术有限公司

Smoke-gas treatment system in production and pouring process of submerged arc furnace

Owner:NINGBO HELANSHAN METALLURGY

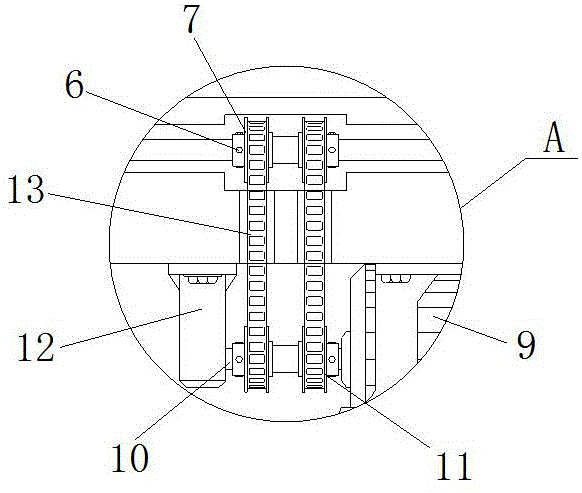

Liquid package

PendingCN109436545AStable flowStable flow rateClosuresClosure using stoppersInternal pressureBlock structure

The invention discloses a liquid package comprising a packaging container, an inner plug and a fiber body. The inner plug is mounted on an opening of the packaging container and is provided with at least two guiding holes for communicating the inside of the packaging container with the outside; the fiber body is installed at the upper end of the inner plug, the lower end of the fiber body covers the guiding holes, one side of the fiber body is connected with at least one conveying tooth, and the conveying teeth and the fiber body are both of porous fiber block structures; when the liquid package is tilted to pour liquid, the liquid in the packaging container flows out of the fiber body through at least one guiding hole, and outside air is supplied to the inside of the packaging container through the at least one remaining guiding hole. In the using process, the liquid flows out to enter the fiber body through the guiding holes, the outside air enters the inside of the packaging container from partial guiding holes, reduction of the internal pressure of the packaging container is avoided, the liquid can continuously flow out, and porous fibers can stabilize the flow rate of the liquid. According to the scheme, stable liquid discharging can be achieved without manually extruding the liquid package, the liquid package is convenient to use, and the liquid package has the good use experience.

Owner:INFINITUS (CHINA) CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap