Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Boiler water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boiler water is liquid water within a boiler, or in associated piping, pumps and other equipment, that is intended for evaporation into steam. The term may also be applied to raw water intended for use in boilers, treated boiler feedwater, steam condensate being returned to a boiler, or boiler blowdown being removed from a boiler.

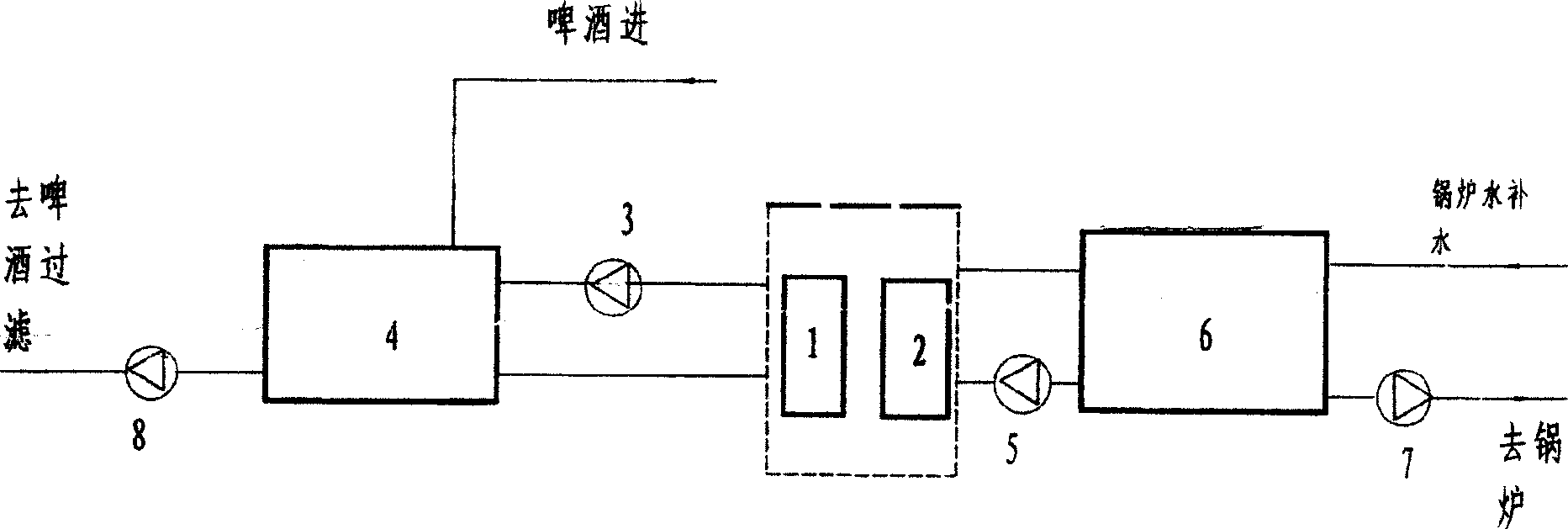

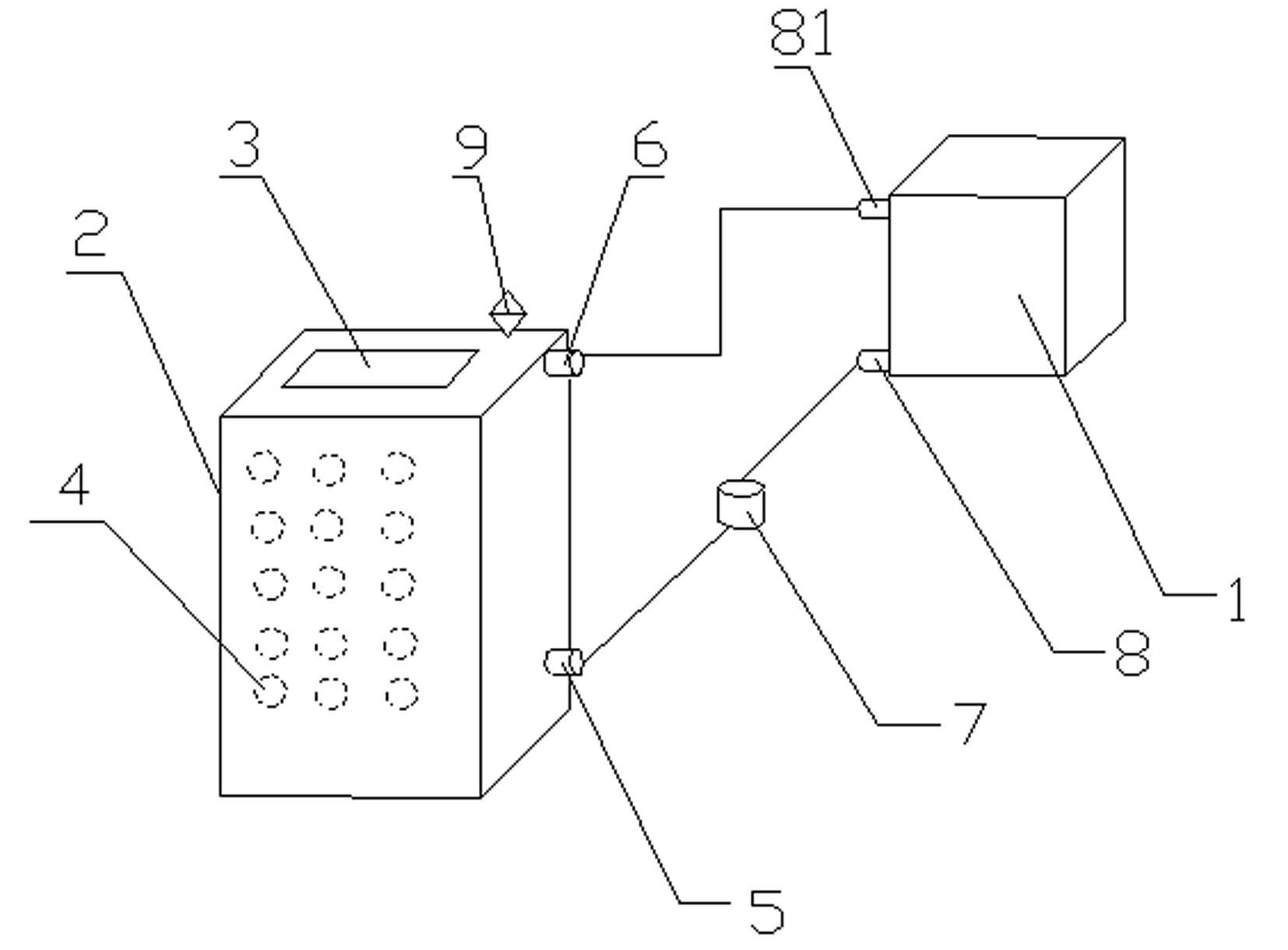

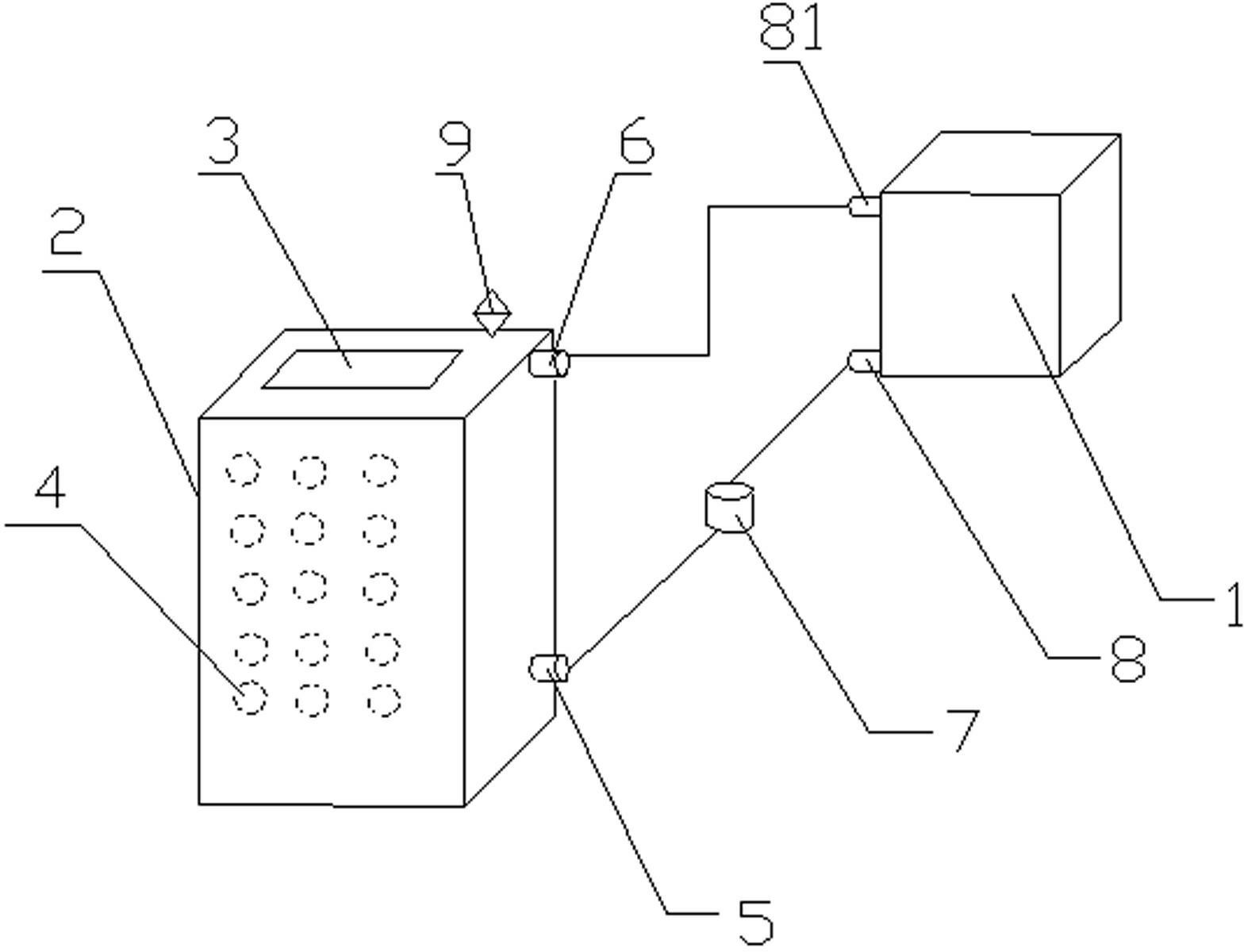

Full heat utilizing device for cooling beer fermentation tank

InactiveCN1749385AImprove efficiencyEasy to installBeer brewingWater source heat pumpDihydrogen oxide

Owner:DALIAN BAOGUANG ENERGY SAVING AIR CONDITIONING EQUIP +1

Boiler waste heat recovery device

InactiveCN102287805ARealize secondary recycling and reuseRaise the water temperatureFluid heatersCombustion technology mitigationWaste heat recovery unitFlue gas

Owner:PENGLAI HUIYANG FOOD

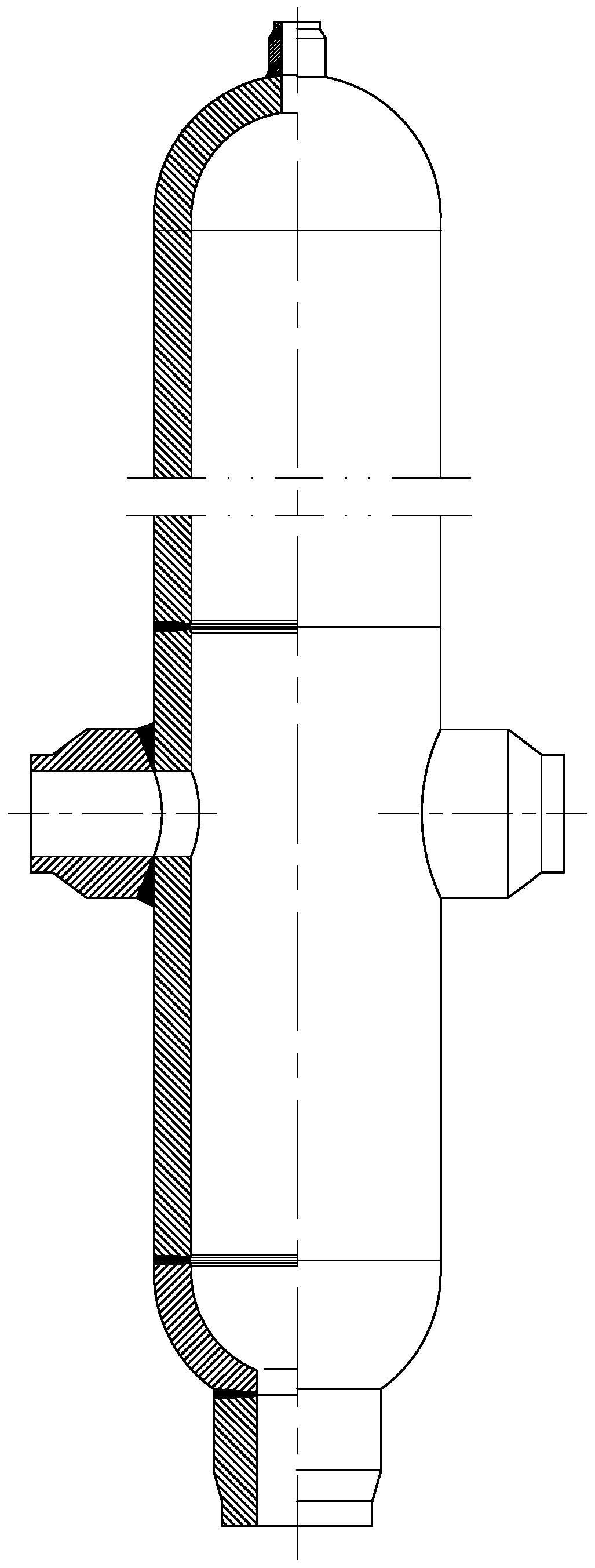

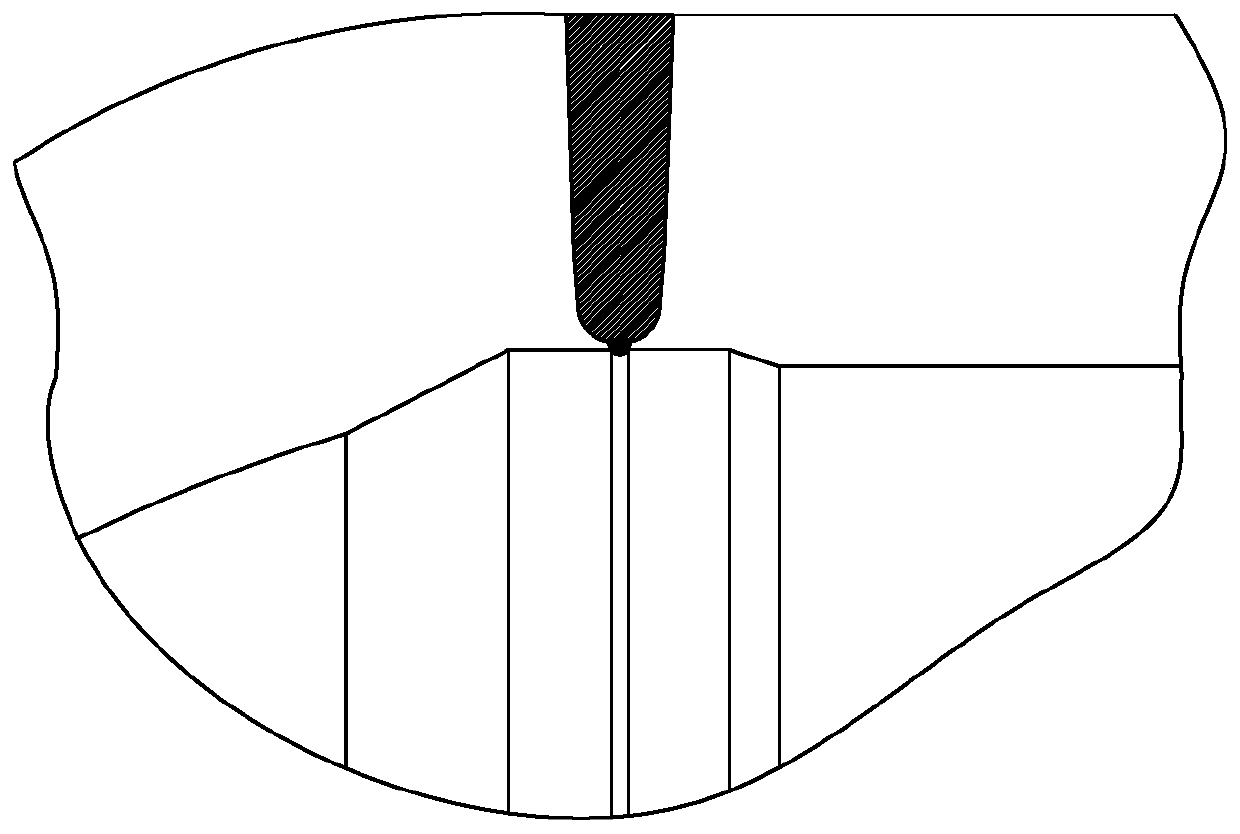

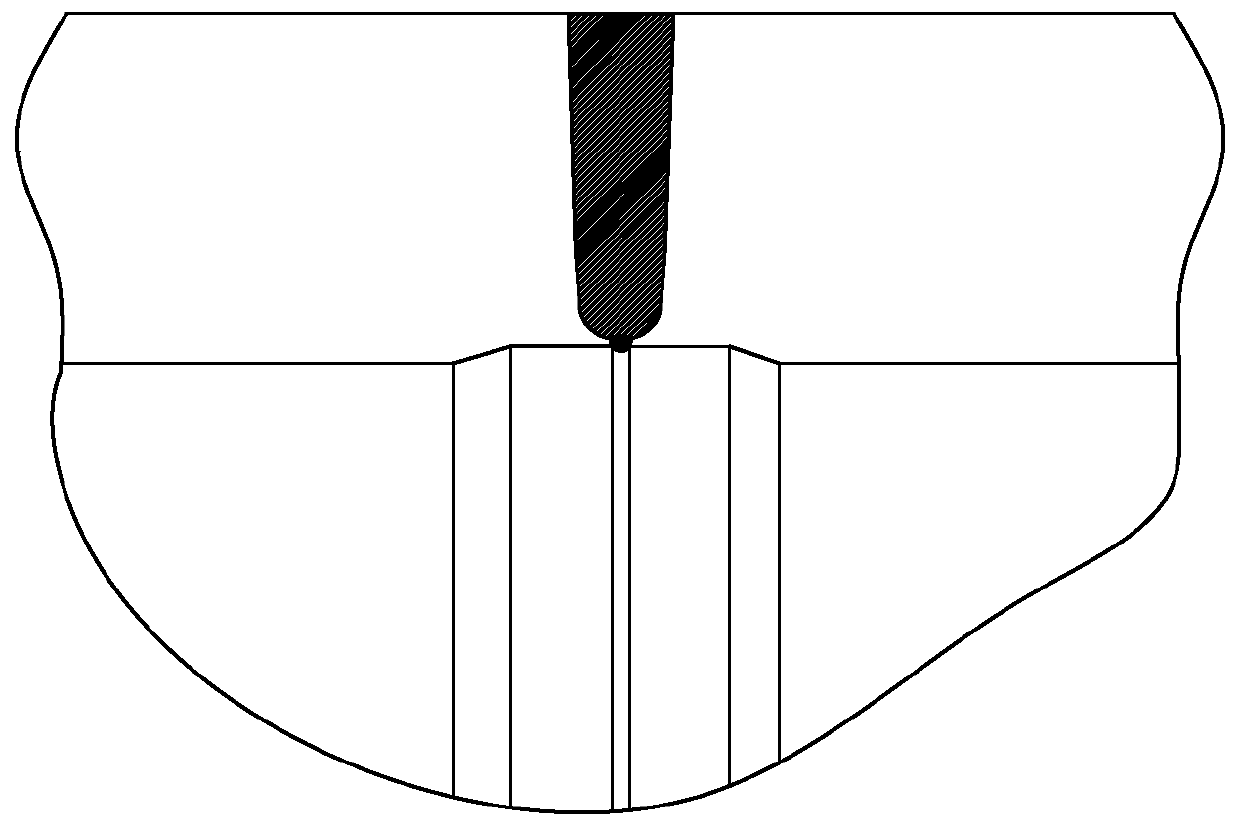

Water storage tank circular seam structure and manufacturing method thereof

ActiveCN109945155AReduce consumptionReduce the positive deviation of wall thicknessSteam boilersSteam boilers componentsManufacturing technologyPower station

Owner:HARBIN BOILER

Intelligent control system and method for boiler water quantity of hydration workshop

InactiveCN110319595AEasy to adjustImprove efficiencyFluid heatersLevel controlEngineeringIntelligent control

Owner:XINJIANG XITA ENERGY

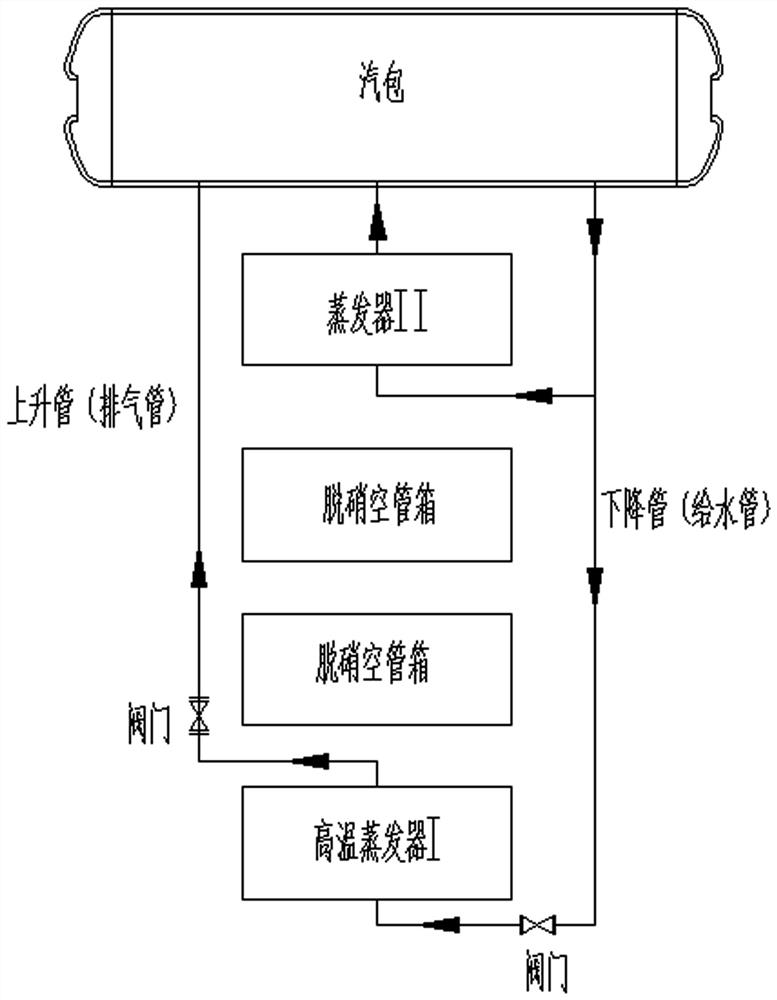

A vertical waste heat boiler operation method for glass melting furnace flue gas treatment

ActiveCN110986015BStable water levelGuaranteed uptimeBoiler controlIncreasing energy efficiencyFlue gasProcess engineering

Owner:SHENZHEN TRIUMPH TECH ENG

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap