A vertical waste heat boiler operation method for glass melting furnace flue gas treatment

A technology of waste heat boiler and glass melting furnace, which is applied in the steam generation method using heat carrier, waste heat treatment, furnace, etc. It can solve the problems of insufficient water power of the high-temperature evaporator of the boiler, unstable water level of the boiler drum, etc., and achieve boiler operation It is normal and safe, solves the problem of insufficient water power, and has the effect of simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

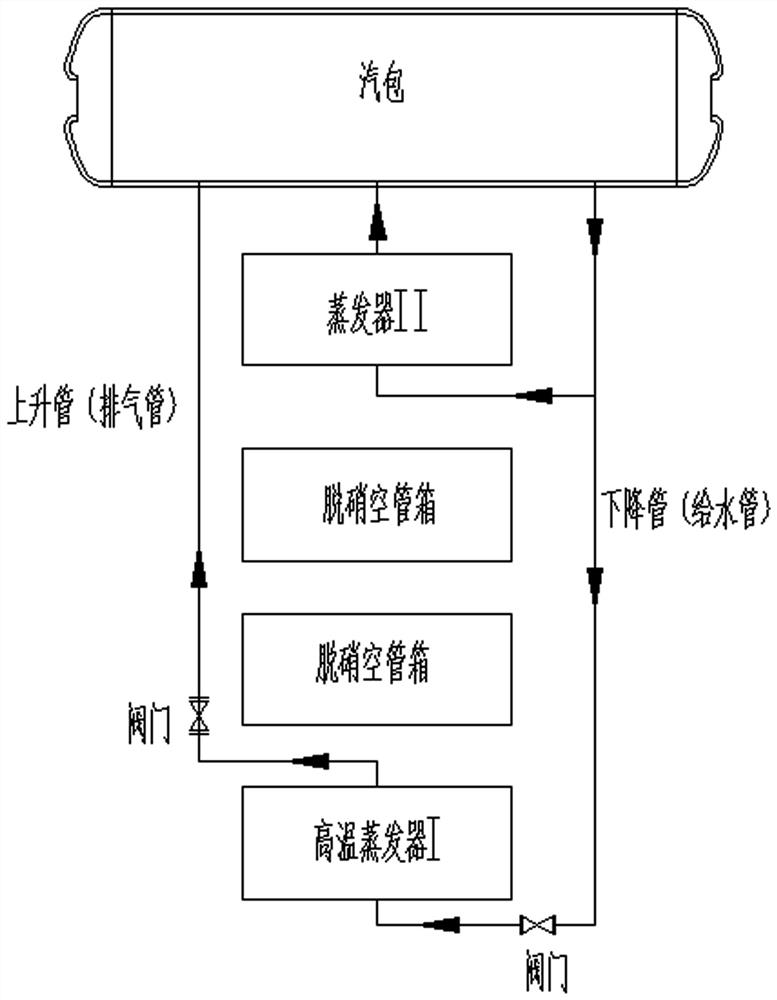

[0017] like figure 1 As shown, the present invention provides a method for operating a vertical waste heat boiler for glass melting furnace flue gas treatment, including a vertical waste heat boiler (not shown in the figure) connected to the glass melting furnace, a vertical waste heat boiler drum The downpipe (water supply pipe) connected on one side is respectively connected to the high-temperature evaporator and the evaporator, and the high-temperature evaporator and the evaporator are respectively connected to the other side of the steam drum through the uppipe (exhaust pipe), which is characterized by the following steps:

[0018] 1) There are valves in the rising pipe and the descending pipe on both sides of the high temperature evaporator;

[0019] 2) When the flue gas volume and flue gas temperature of the glass melting furnace meet the design parameters, that is, the flue gas temperature of the glass melting furnace is between 450 and 500 °C, keep the valves of the downc

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap