Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3 results about "Depth direction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

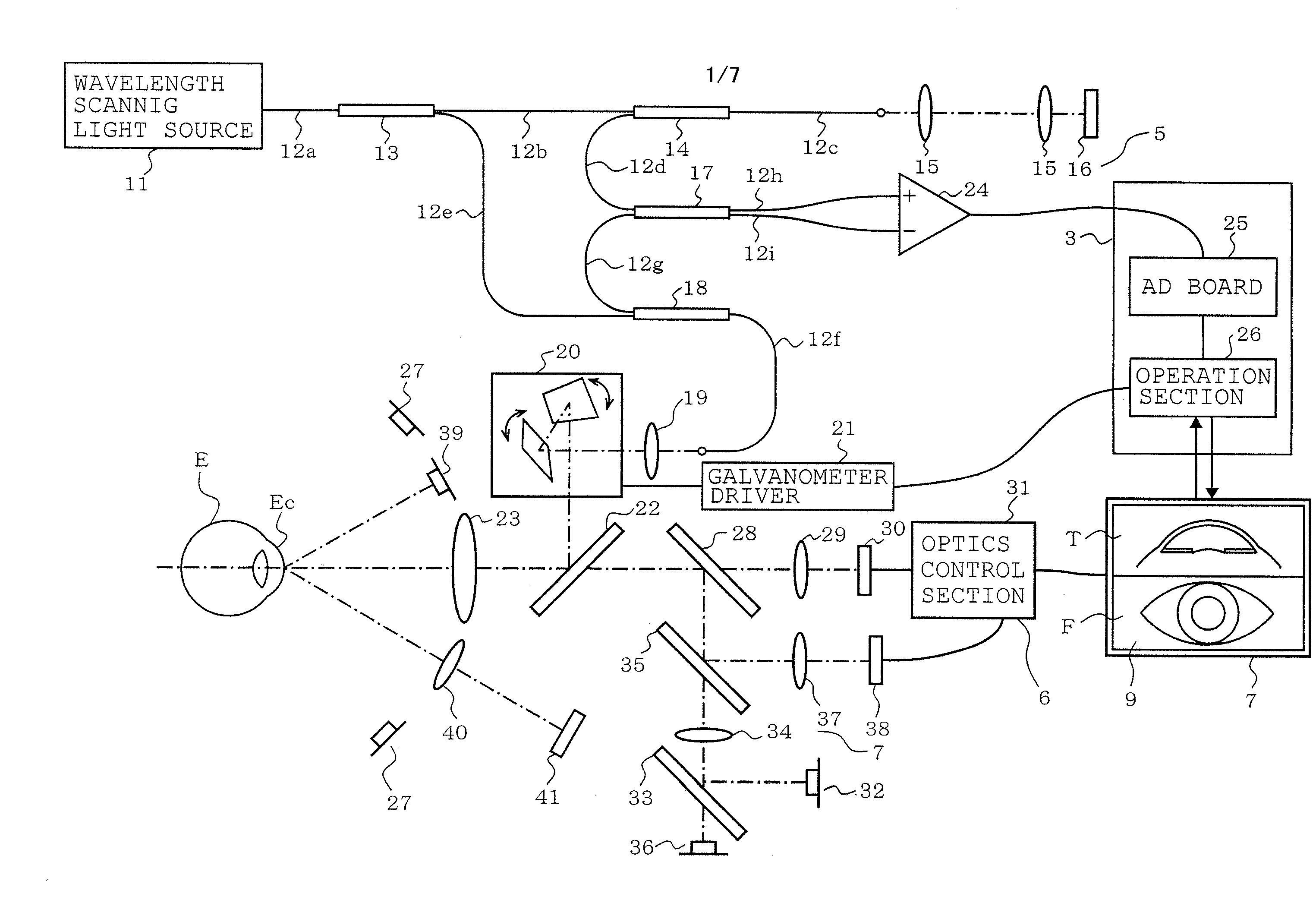

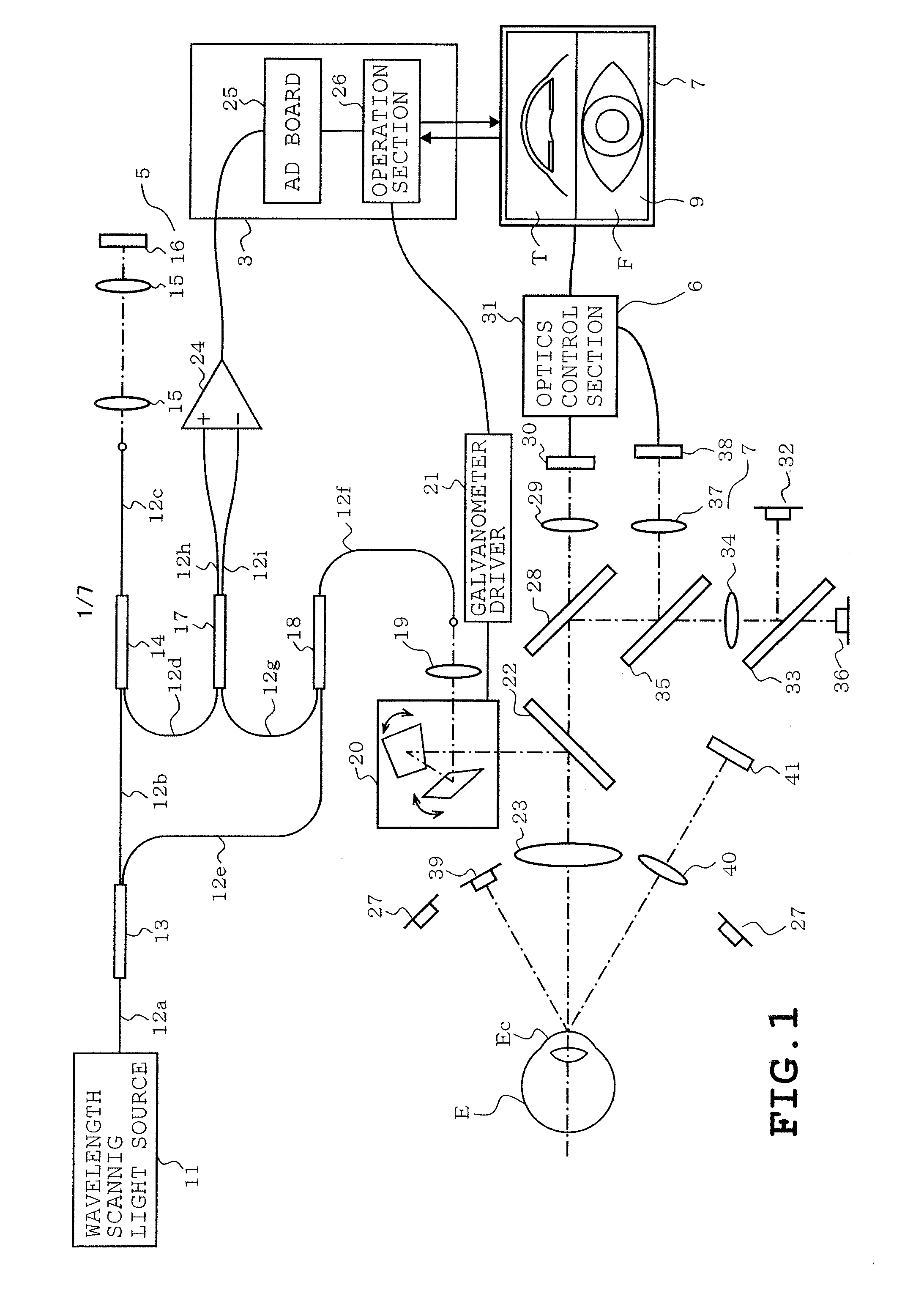

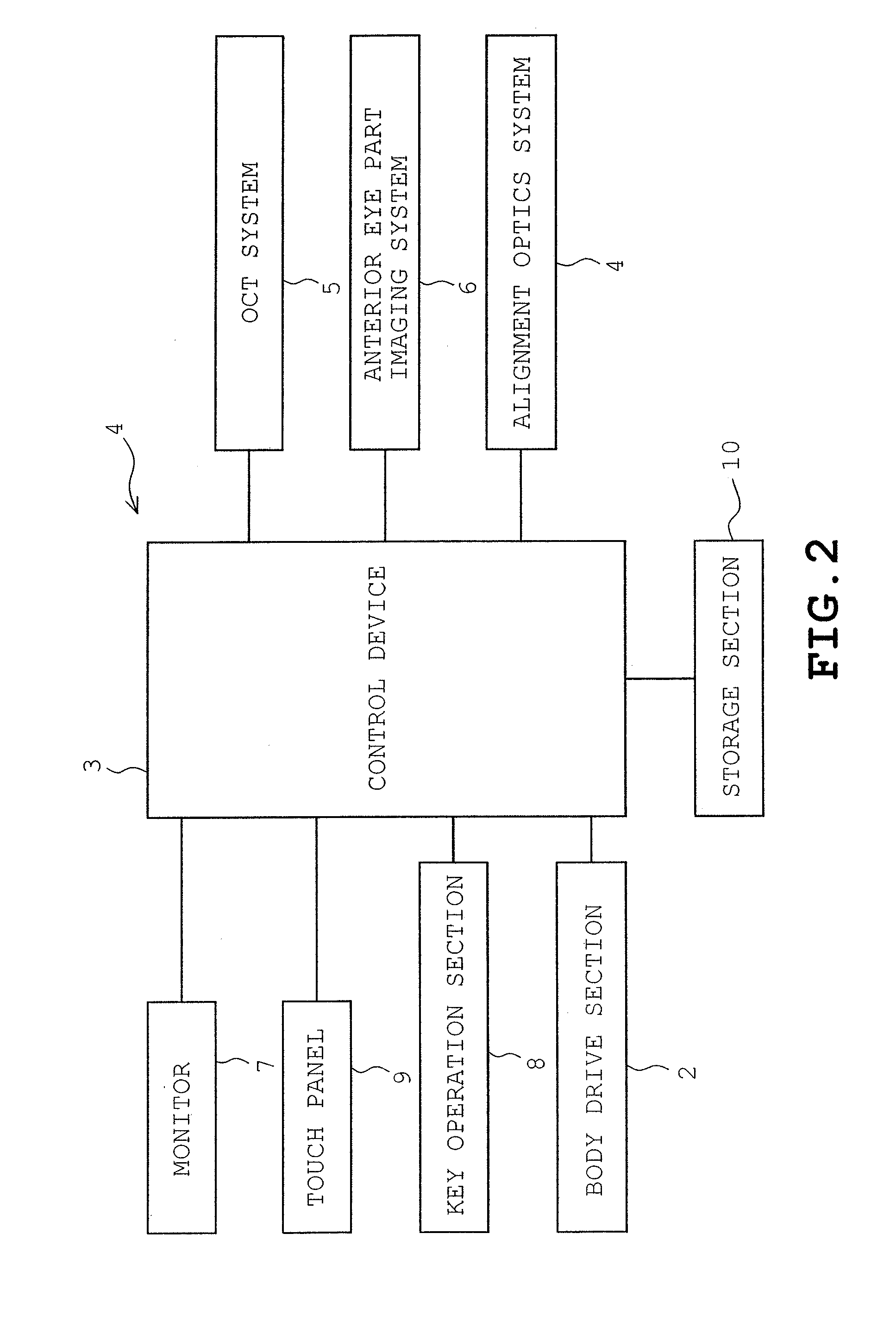

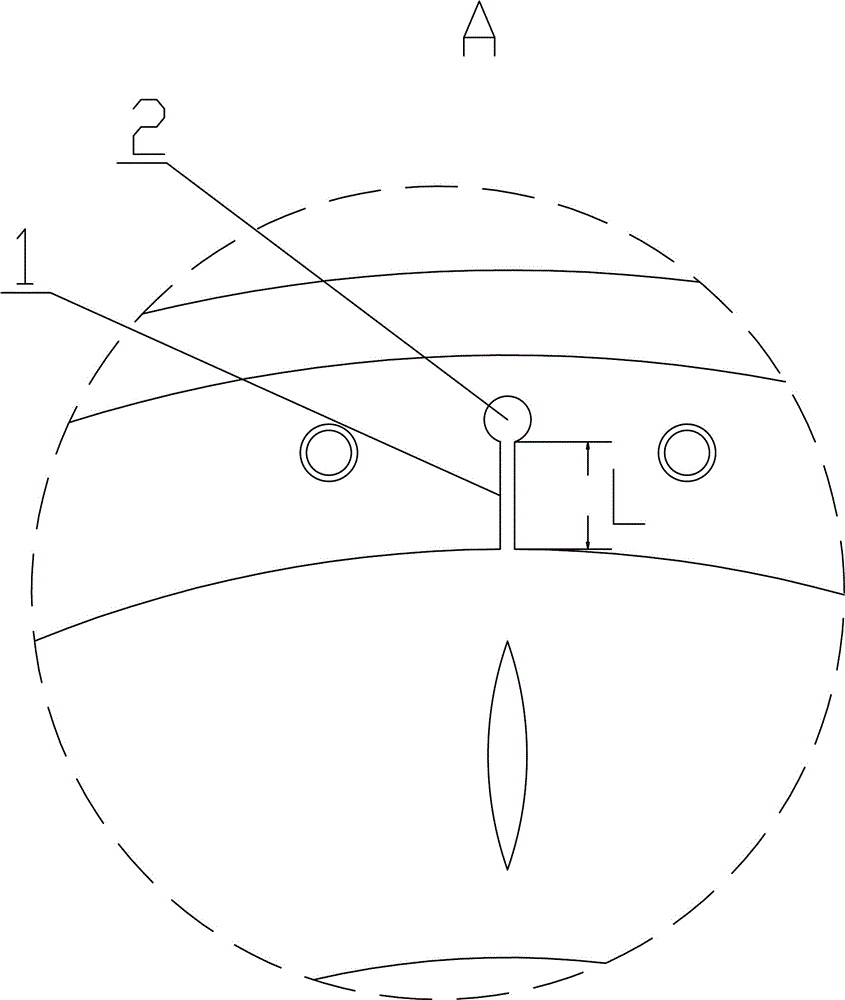

Apparatus and method for imaging anterior eye part by optical coherence tomography

ActiveUS20090149742A1Short timeShorten the time periodPerson identificationSensorsScan lineOcular imaging

Owner:TOMEY CORP

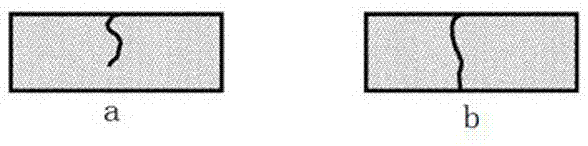

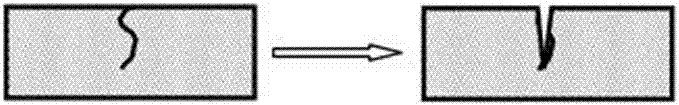

Restorative method for ceramic cores with crack defects

Owner:DONGFANG TURBINE CO LTD

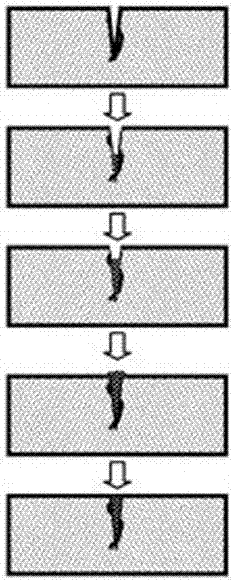

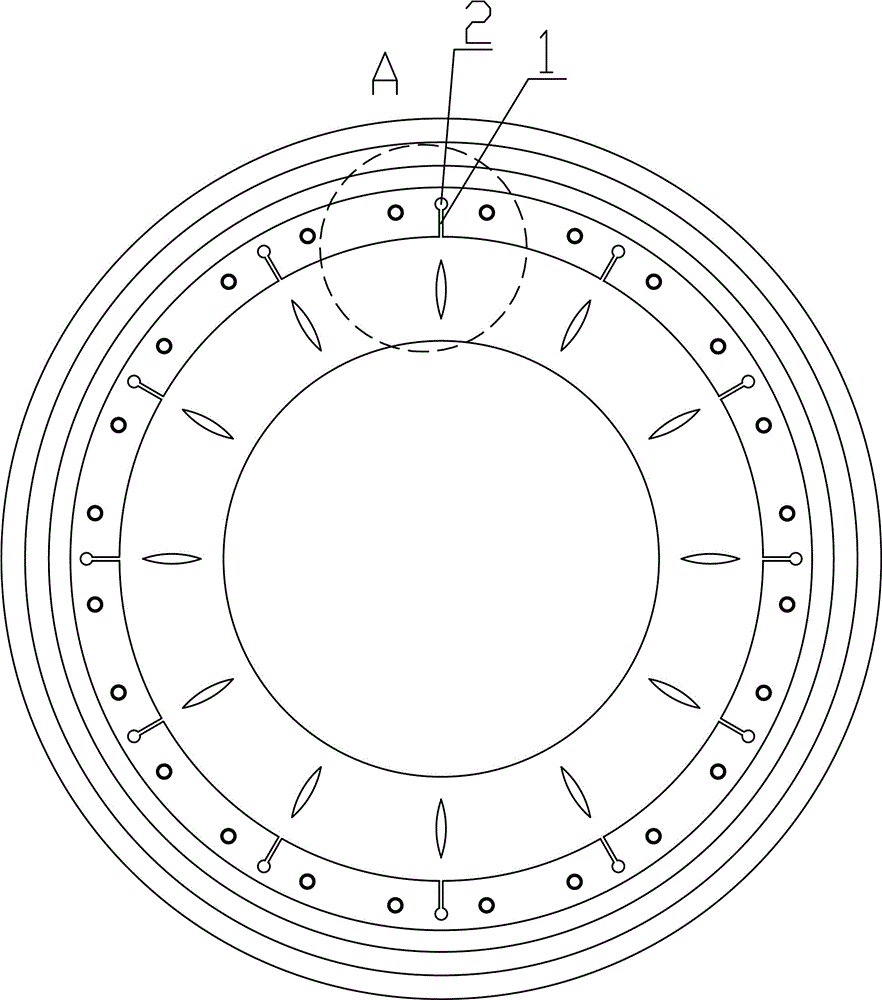

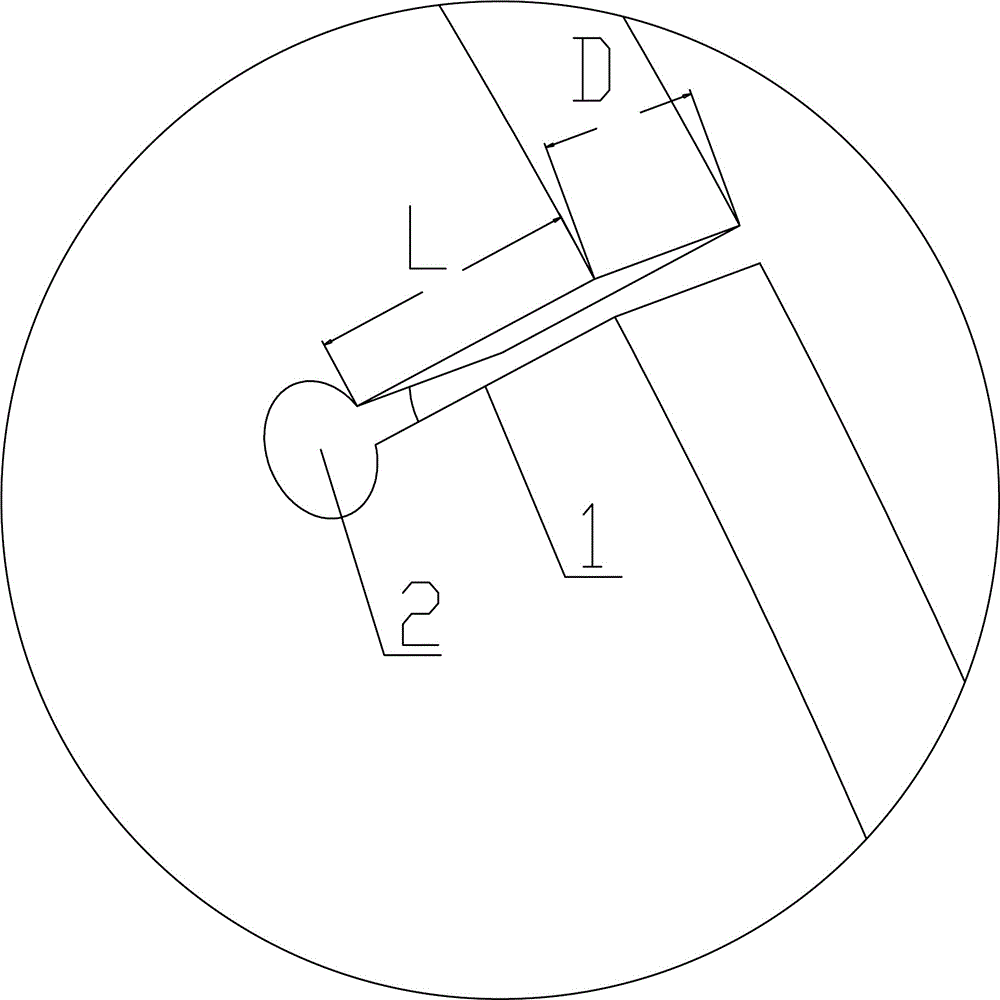

Method for carrying out planing machining for narrow grooves by virtue of numerically-controlled boring and milling machine

InactiveCN105642990ASolve processing problemsImprove processing efficiencyPlaning/slotting toolsPlaning/slotting machinesNumerical controlMilling cutter

Owner:YICHANG MARINE DIESEL ENGINE

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap