Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Hot stamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot stamping or foil stamping is a printing method of relief printing in which pre-dried ink or foils are transferred to a surface at high temperatures. The non-polluting method has diversified since its rise to prominence in the 19th century to include a variety of colors and processes. After 1970s, hot stamping became one of the important methods of decoration on the surface of Plastic Products. Hot Stamping technology for plastic is now using for Electric Components (including TV frame, Audio components, Refrigerators etc.,) cosmetic containers (lipstick, cream, mascara, shampoo bottle etc), automobile parts (interior and exterior materials).

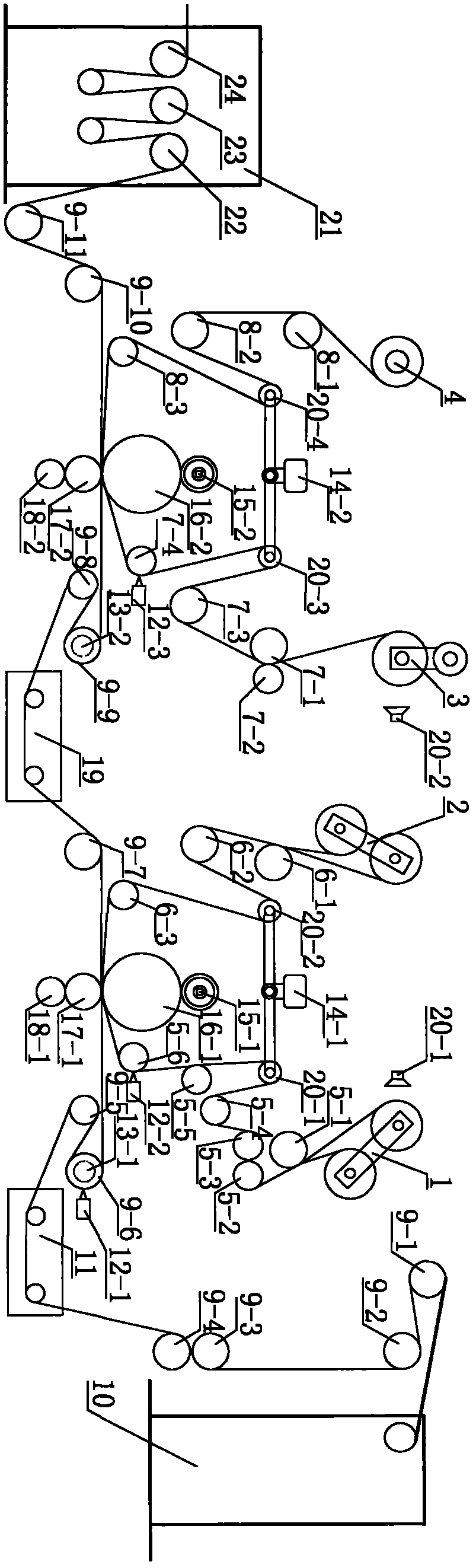

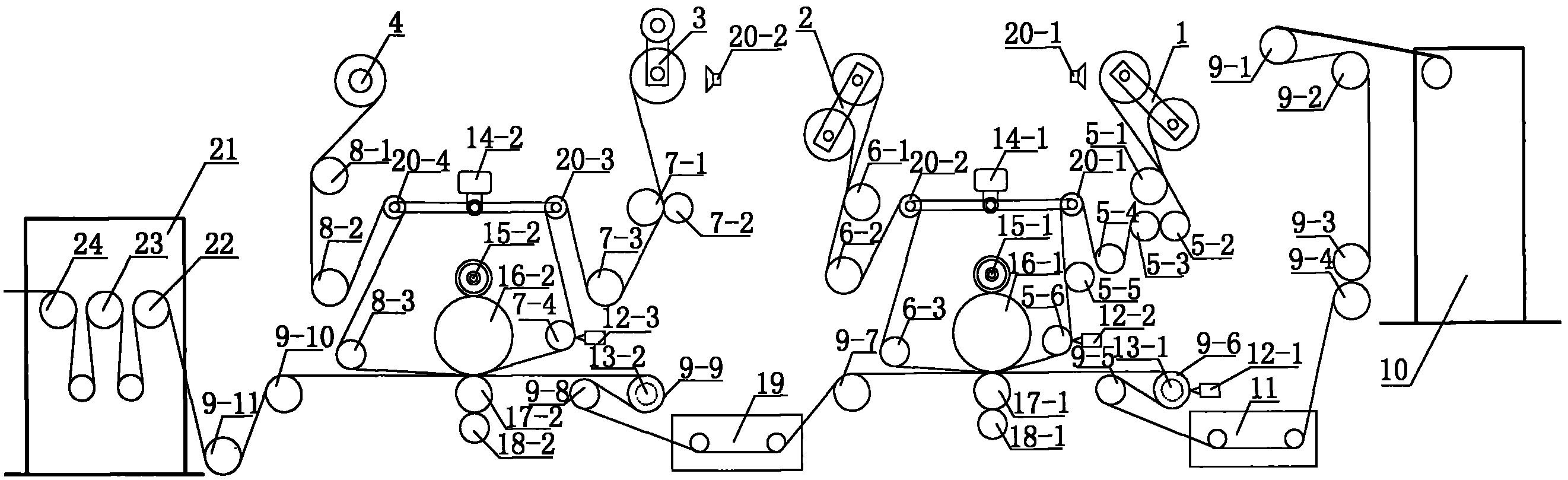

One-step forming method for online hot stamping and concave-convex die cutting of web gravure printing

Owner:TONGXIANG PRINTING

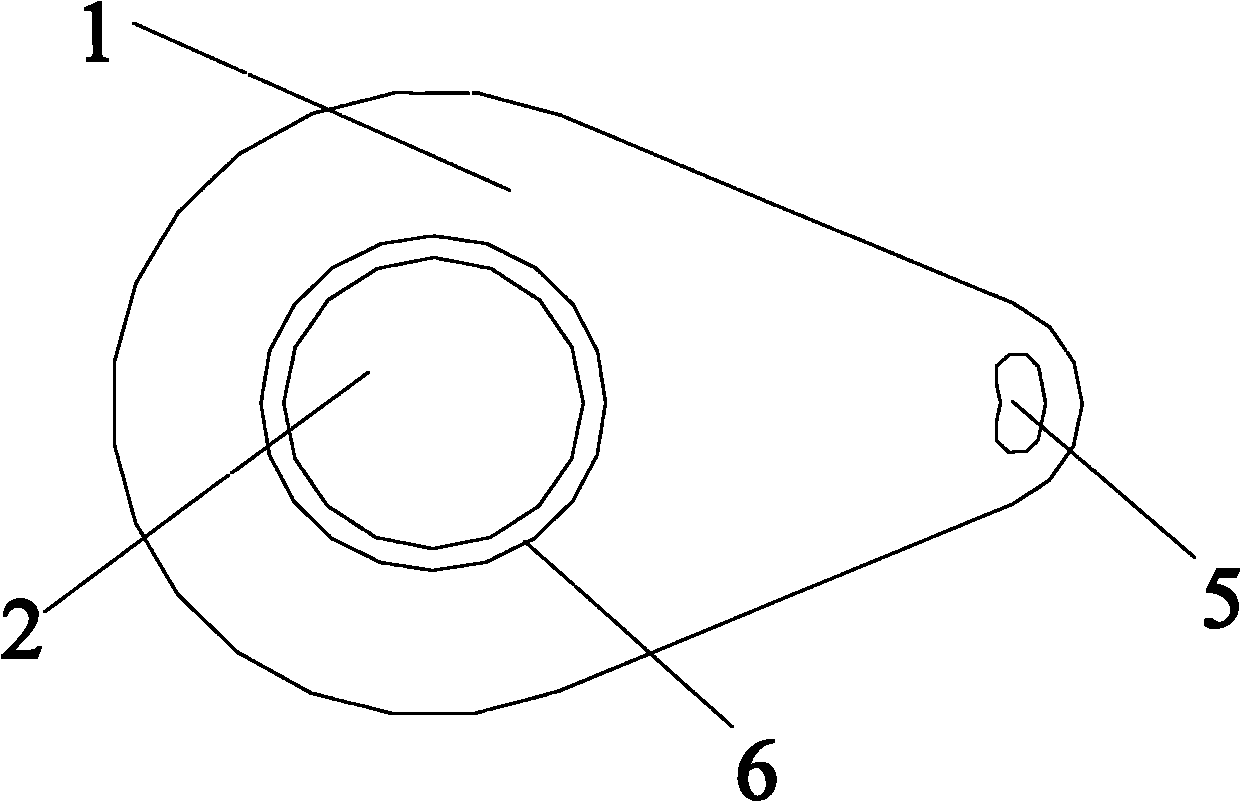

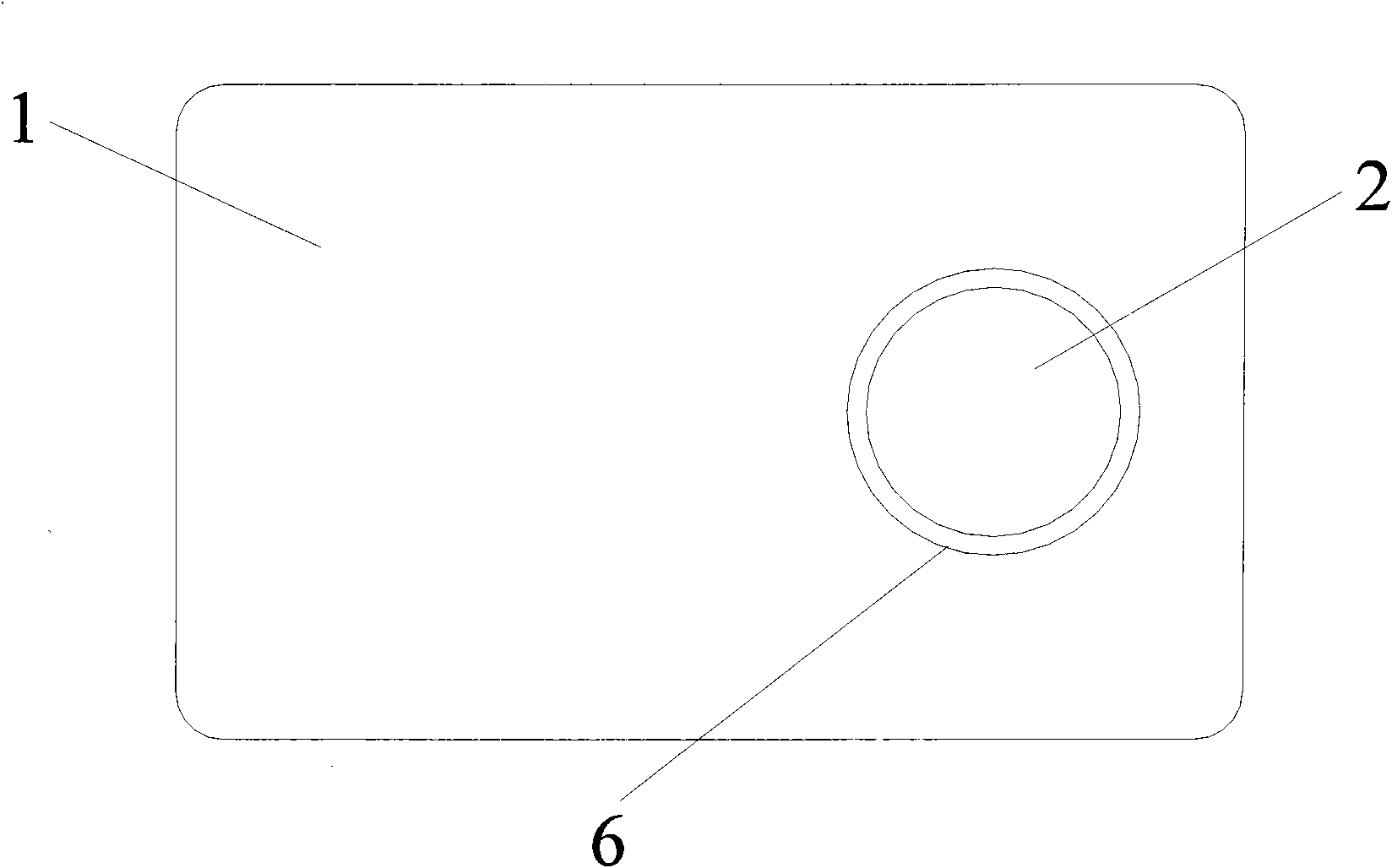

Embedded smart card and manufacturing method thereof

InactiveCN101882232AAvoid discarding defectsReduce maintenance costsRecord carriers used with machinesHot stampingEngineering

Owner:上海卡美循环技术有限公司

Packaging box printing process for UV-flashing stereoscopic pattern printing

InactiveCN109016906AAccurate printing process positioningGood three-dimensional effectDuplicating/marking methodsPattern printingGraphicsHot stamping

Owner:SUZHOU TONGLI PRINTING TECH

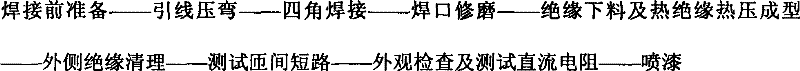

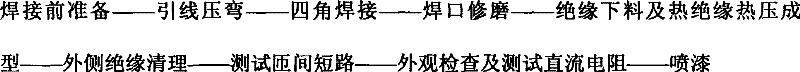

Machining method for magnetic pole winding of four-angle welding motor

InactiveCN101388583BConsistent shapeNeat surfaceApplying solid insulationHot stampingMagnetic poles

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

Antistatic foaming tipping paper printing ink

Owner:江苏卫星新材料股份有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap