Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2 results about "Residual compressive stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In a mathematical sense the term compressive residual stress refers to a negative residual stress condition. For example, if the residual stress condition at a particular location within a body has a value of -100 MPa, it is said to be in a state of compressive residual stress.

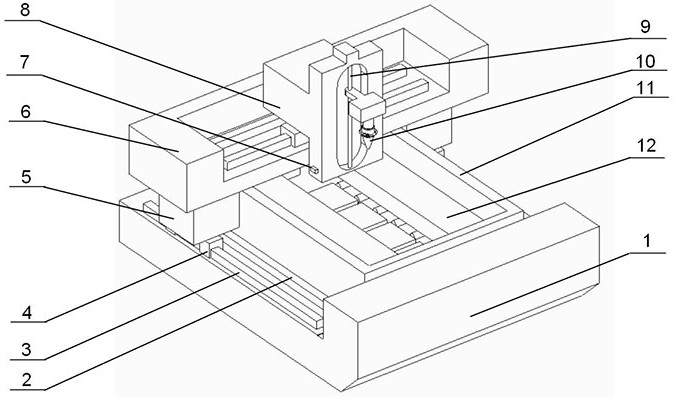

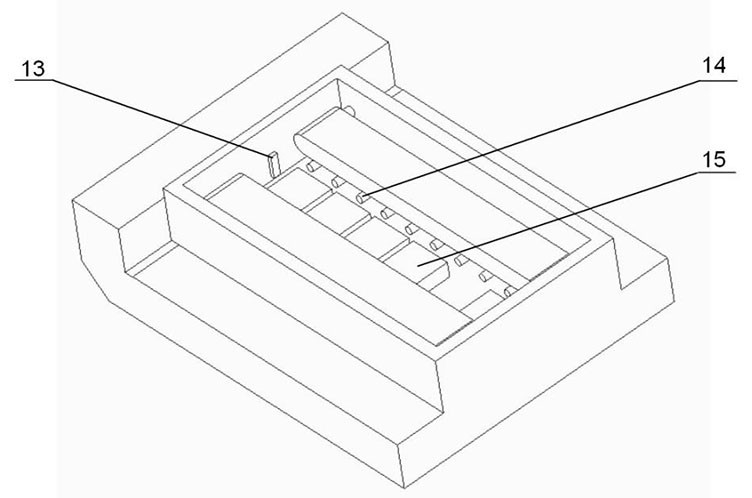

Complete residual compressive stress straightening device and technology for crankshaft

The invention provides a complete residual compressive stress straightening device and technology for a crankshaft. The device and technology solve the technical problems that after an existing crankshaft finished product is accurately ground, a straightening technology is required, cold straightening is not allowed, press rectification cannot be conducted on a press machine, either, and therefore tensile stresses can be formed on the surfaces, opposite to loading force, of the circular bead positions at the two ends easily, the original fatigue strength of the crankshaft is lowered, and cracking can happen easily in the work running process of an engine. The complete residual compressive stress straightening device is provided with an upper rolling swing arm and a lower rolling swing arm. One end of the upper rolling swing arm and one end of the lower rolling swing arm are hinged together through an open pressurization device, and the other end of the upper rolling swing arm is provided with an upper rolling part. The upper rolling part comprises an upper rolling wheel, and the upper rolling wheel is connected with the upper rolling part in a rotating mode. The other end of the lower rolling swing arm is provided with a lower support rolling part. The lower support rolling part comprises lower support roller wheels, and the lower support roller wheels are connected with the lower support rolling part in a rotating mode. The complete residual compressive stress straightening device and technology can be widely applied to correction happening when radial run-out of the crankshaft is out of tolerance.

Owner:TIANRUN IND TECH CO LTD

Method for improving quality of inner wall of laser processing micropore based on dual cavitation effect

ActiveCN114589405AImprove inner wall qualityDecrease produces trendProcess efficiency improvementLaser beam welding apparatusUltrasonic cavitationLaser processing

Owner:SHANDONG UNIV OF TECH

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap