Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Test material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Materials testing is a diligent approach to ensuring that your infrastructure and vital equipment will provide continued production, undergo minimal degradation and are designed with optimal performance in mind. Materials testing can also supply a wealth of information about the materials you are developing or incorporating...

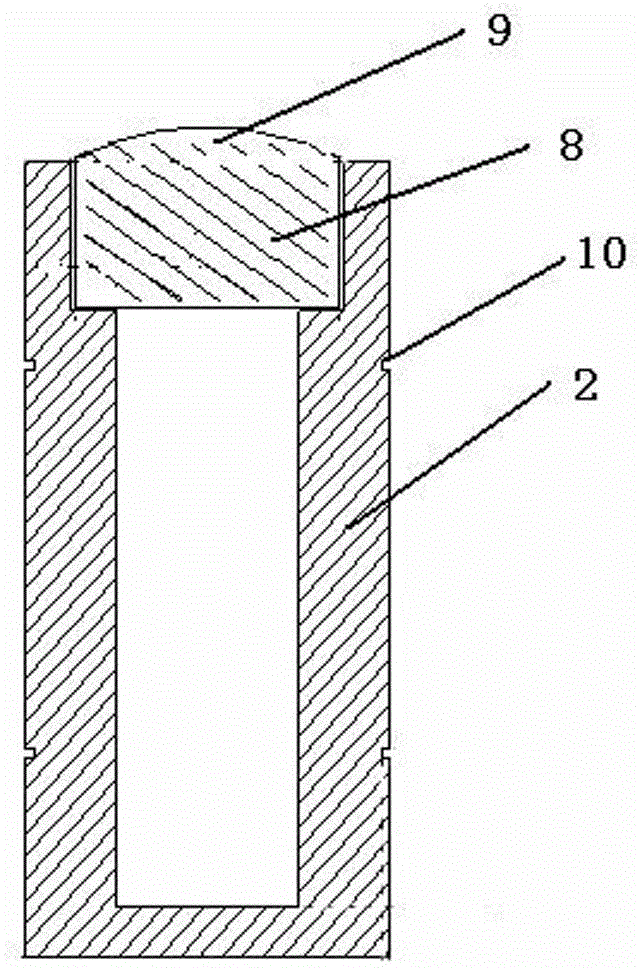

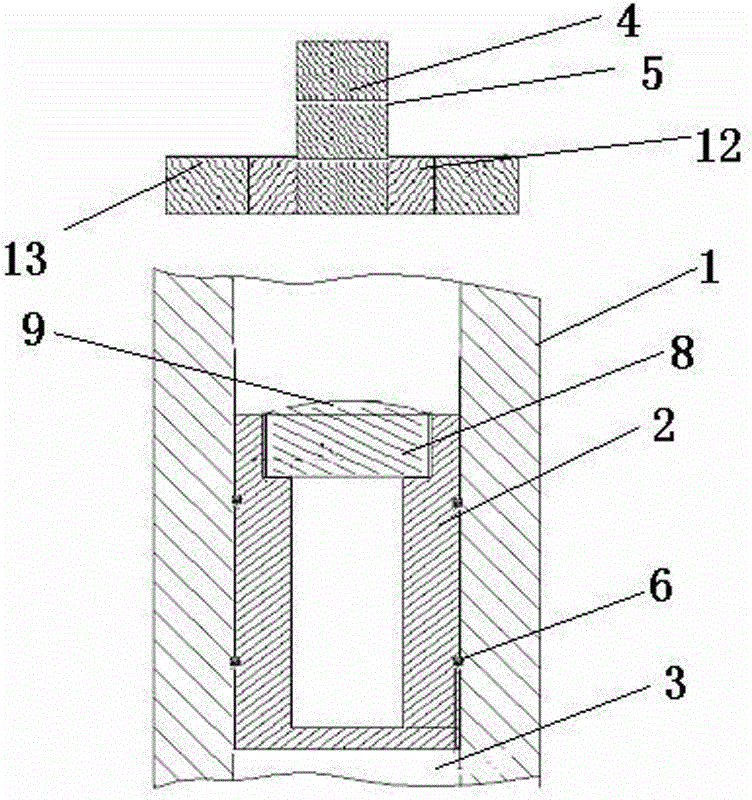

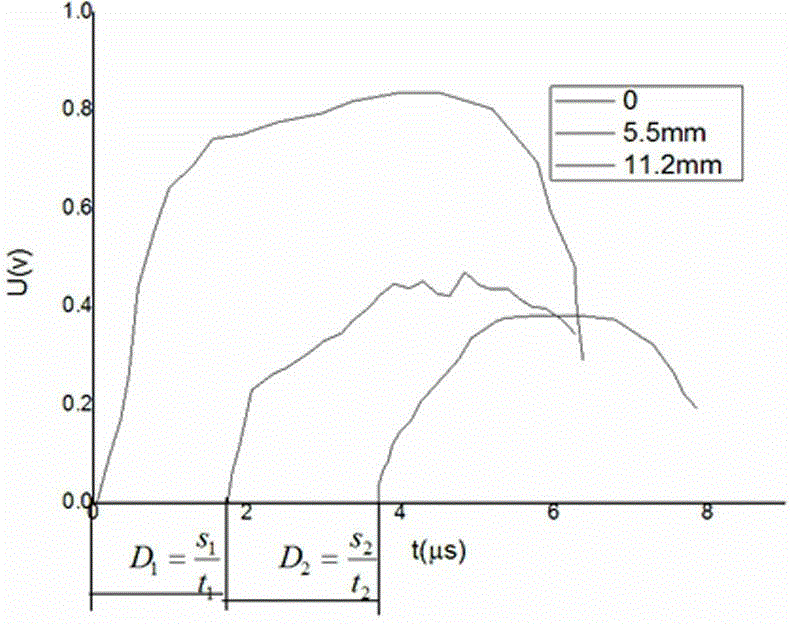

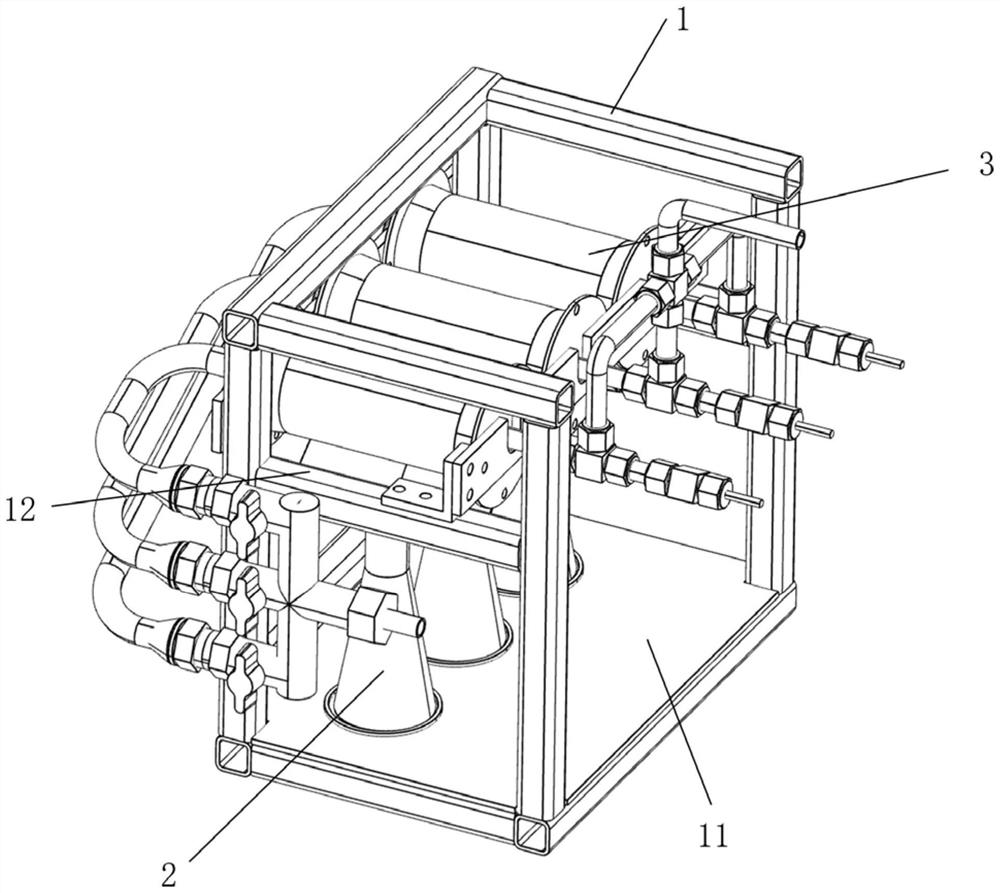

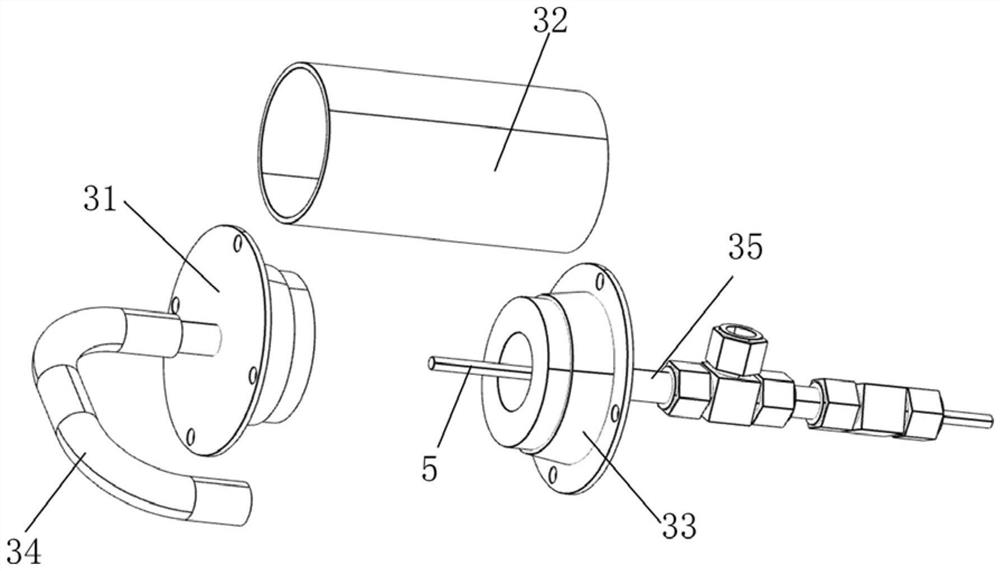

Dynamic effect device for gas-gun testing materials and testing method

InactiveCN104020061AAchieve frictionRealize the test of inertial force effectStrength propertiesRubber ringEngineering

Owner:FUJIAN JIANGXIA UNIV

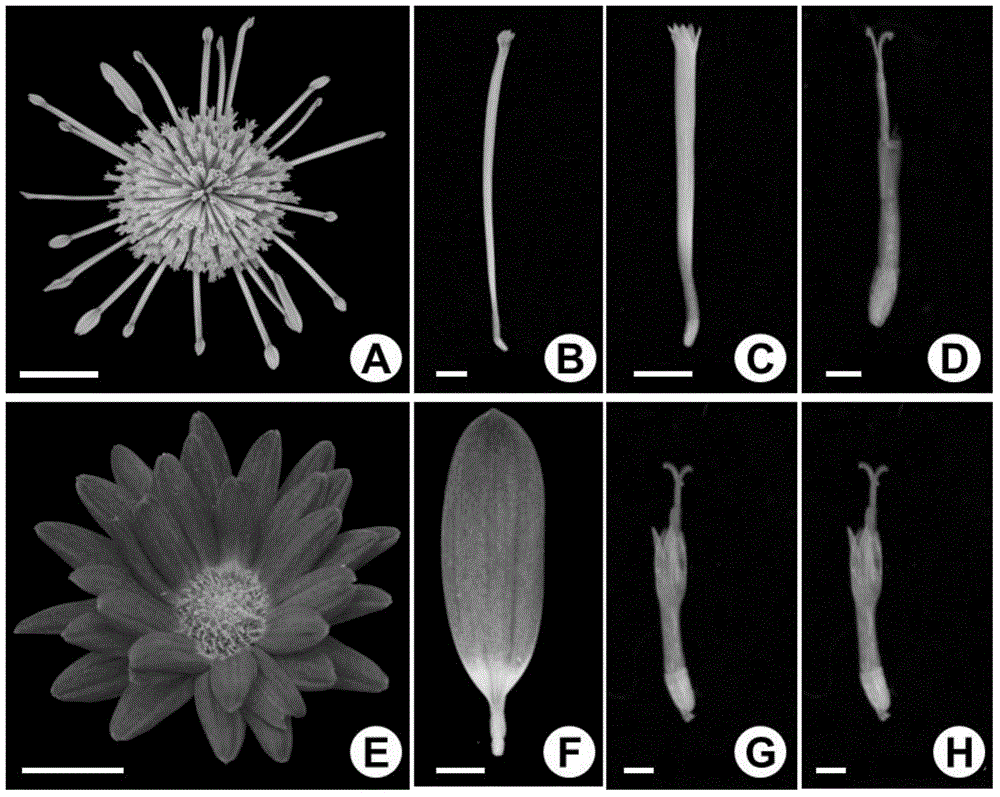

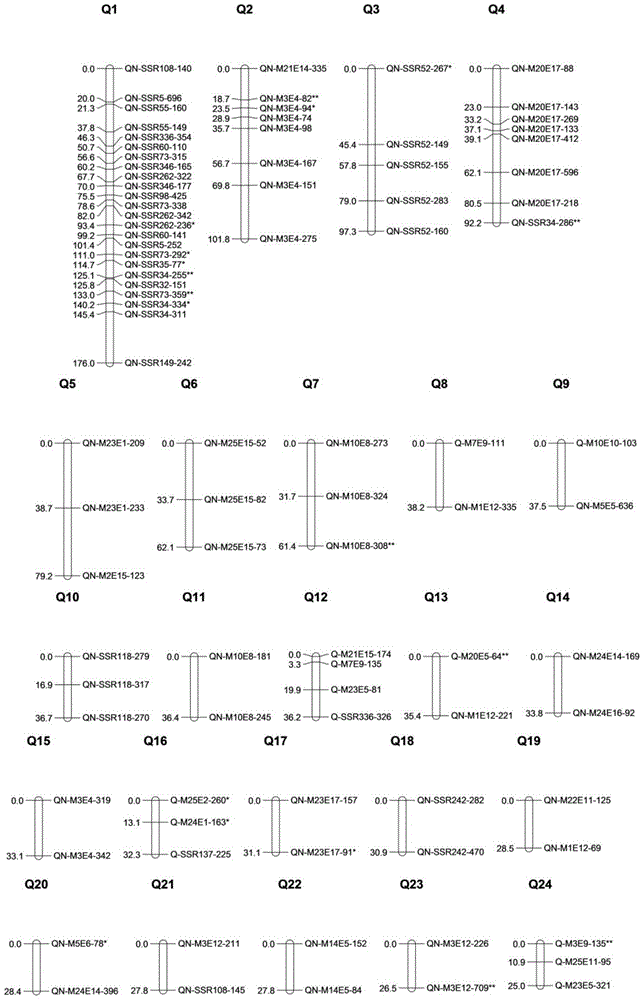

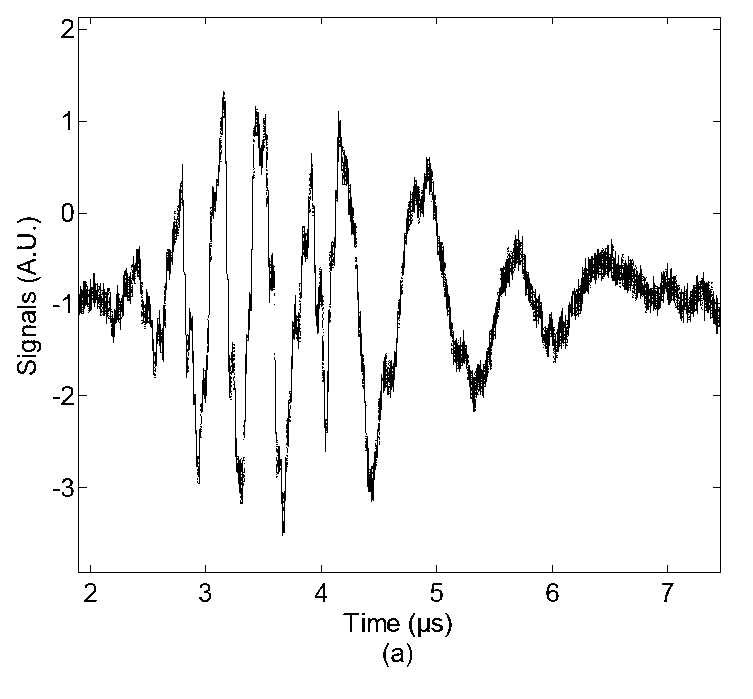

Floral character associated molecular marker screening method of amenone form chrysanthemum and application of method

Owner:NANJING AGRICULTURAL UNIVERSITY

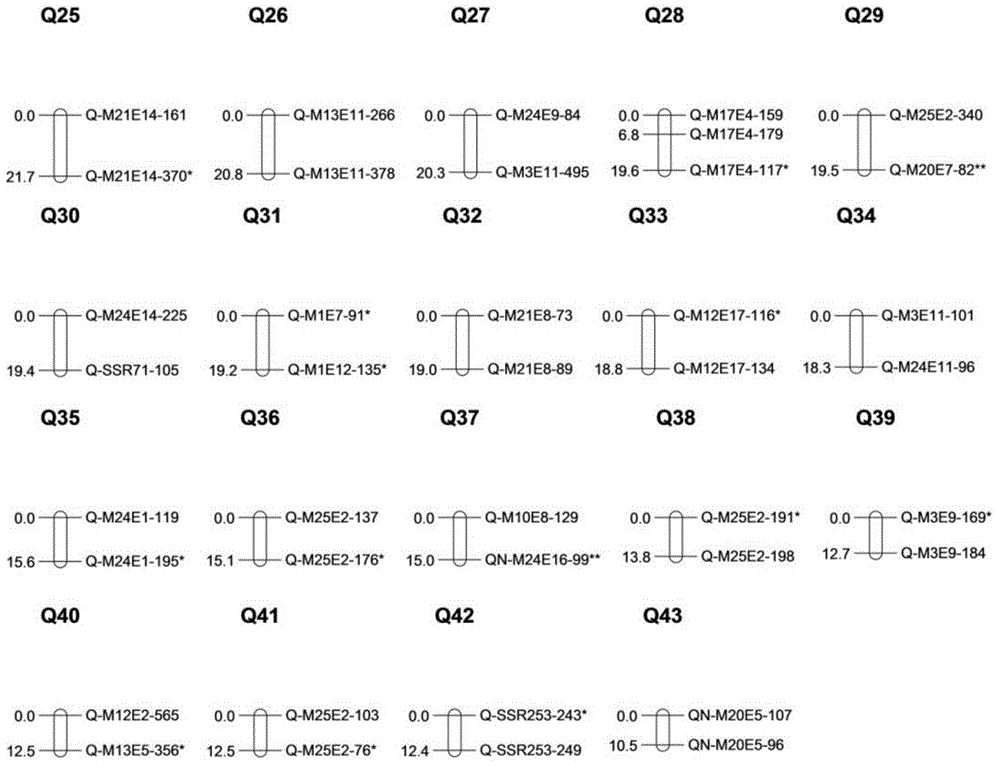

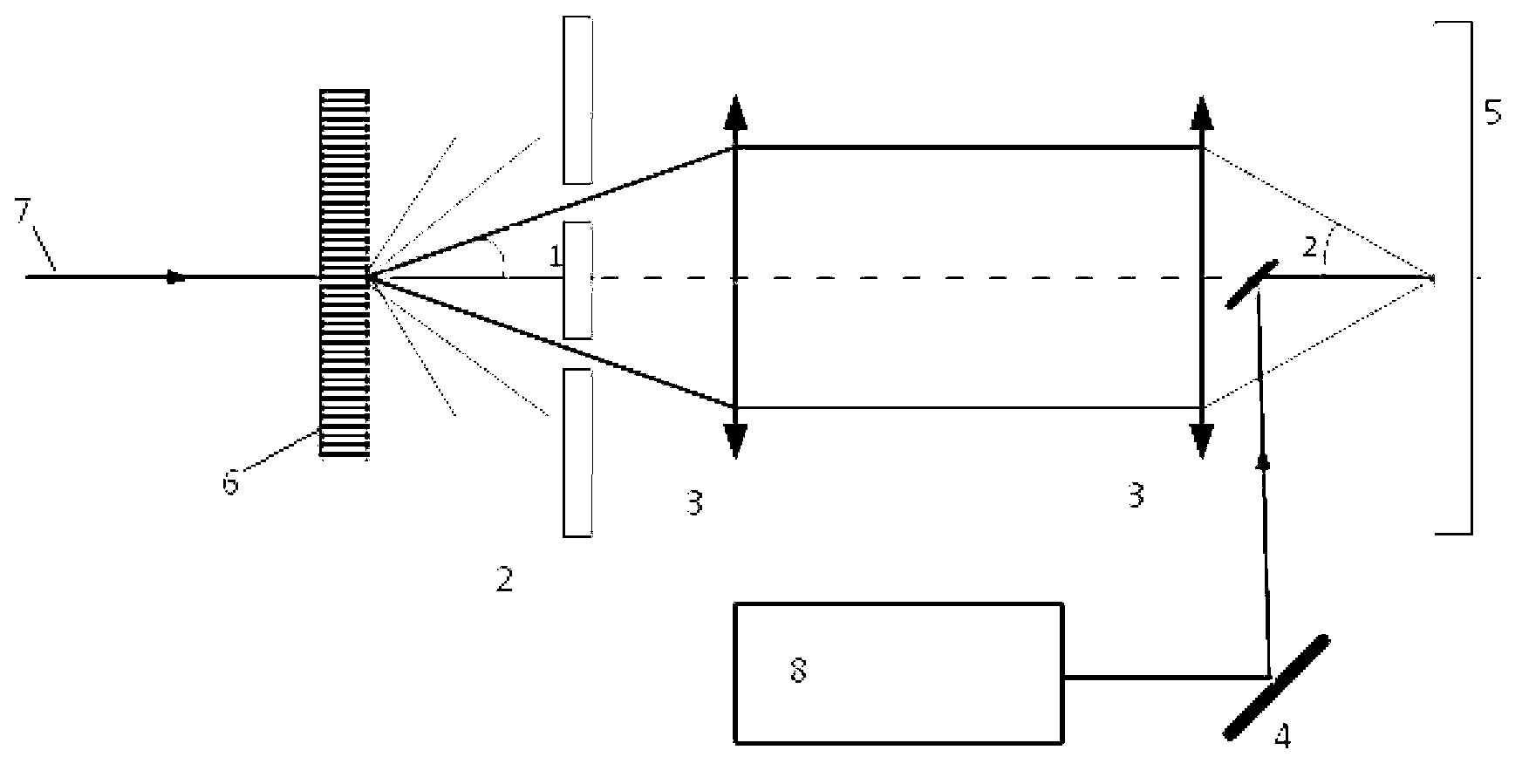

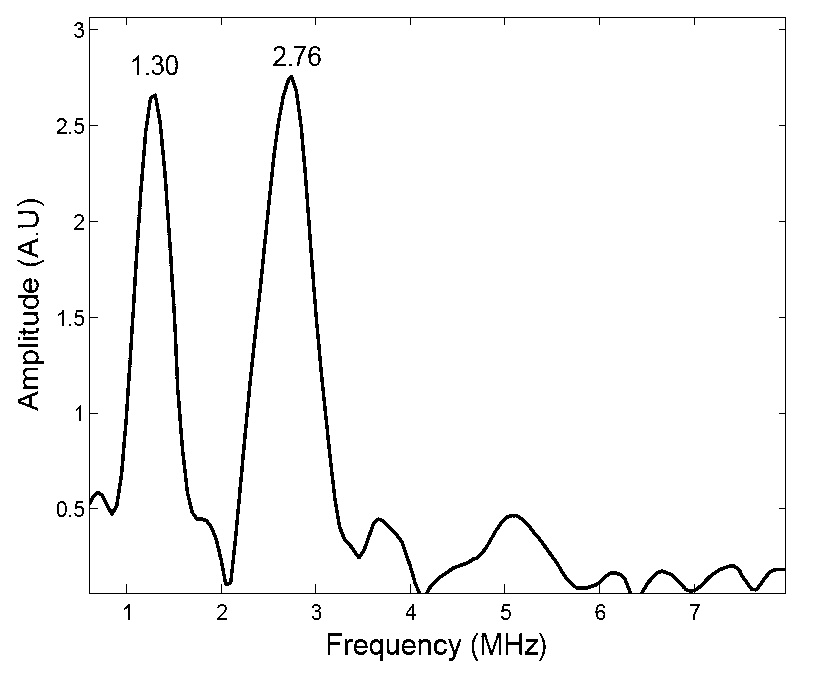

Non-contact detection method for detecting elastic parameter uniformity of material on line

InactiveCN103018170ARealize online characterizationImprove real-time performanceMaterial analysis by optical meansGratingNanosecond

Owner:NANJING BAISISHENG NEW MATERIAL TECH

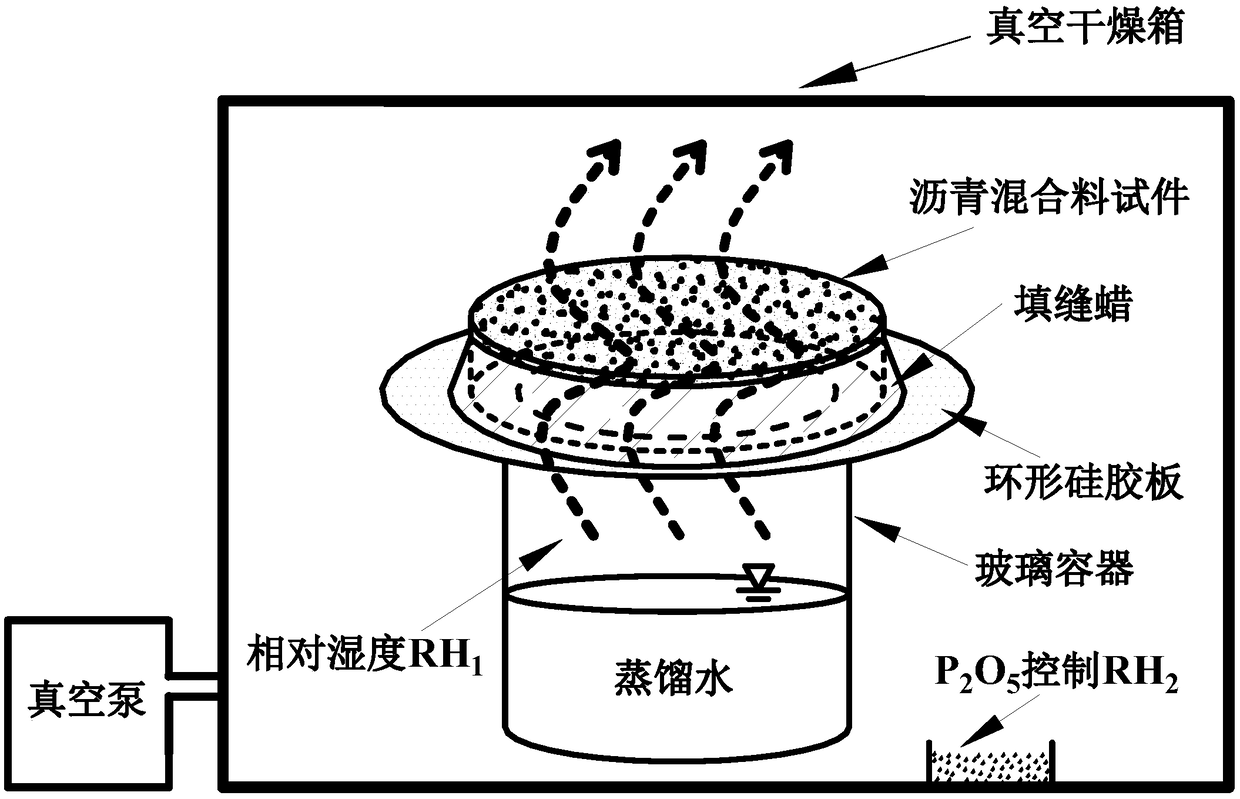

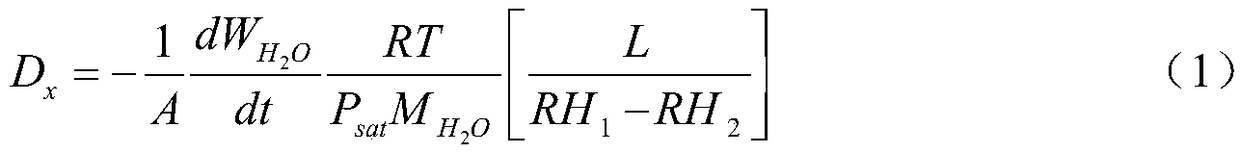

A method for detecting the penetration type water vapor diffusion coefficient of a large-thickness low-porosity asphalt mixture

ActiveCN108776084ARealize humidity gradient driveIncrease humiditySurface/boundary effectPorosityWater vapor

Owner:WUHAN UNIV OF TECH

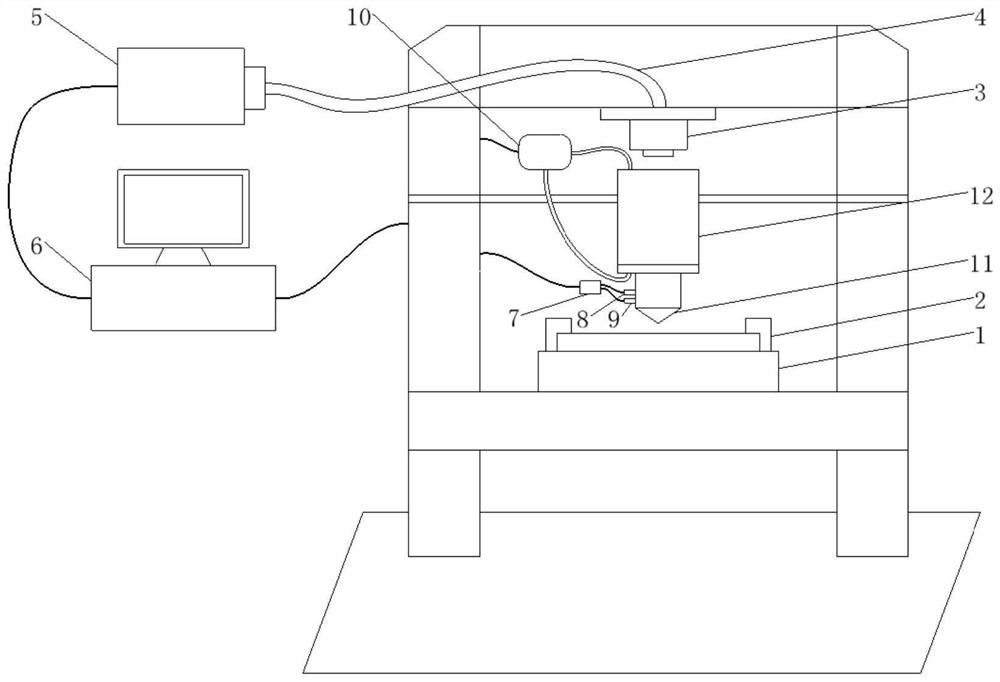

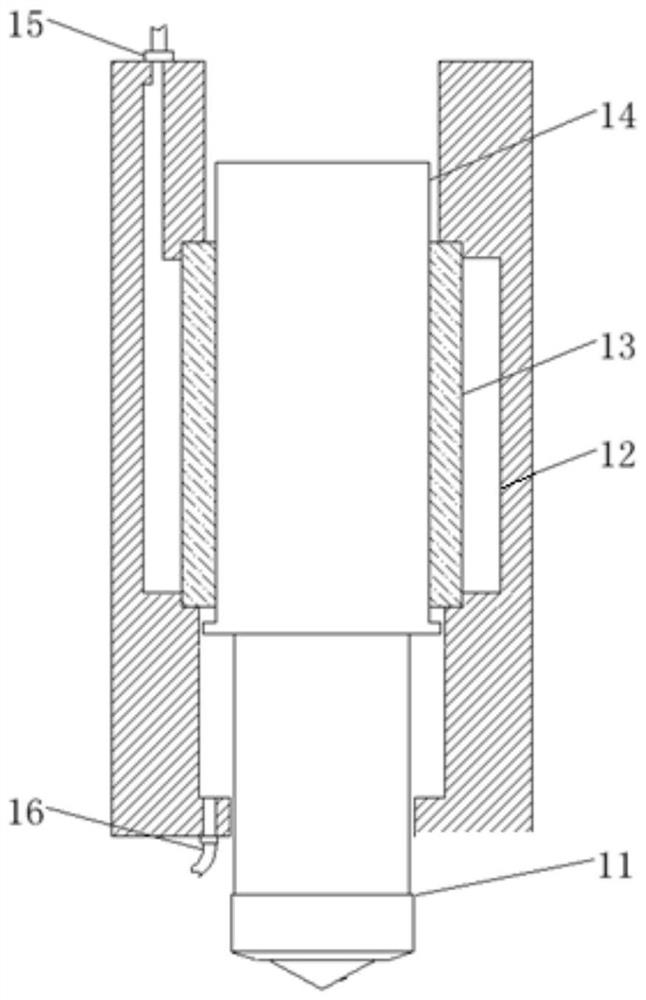

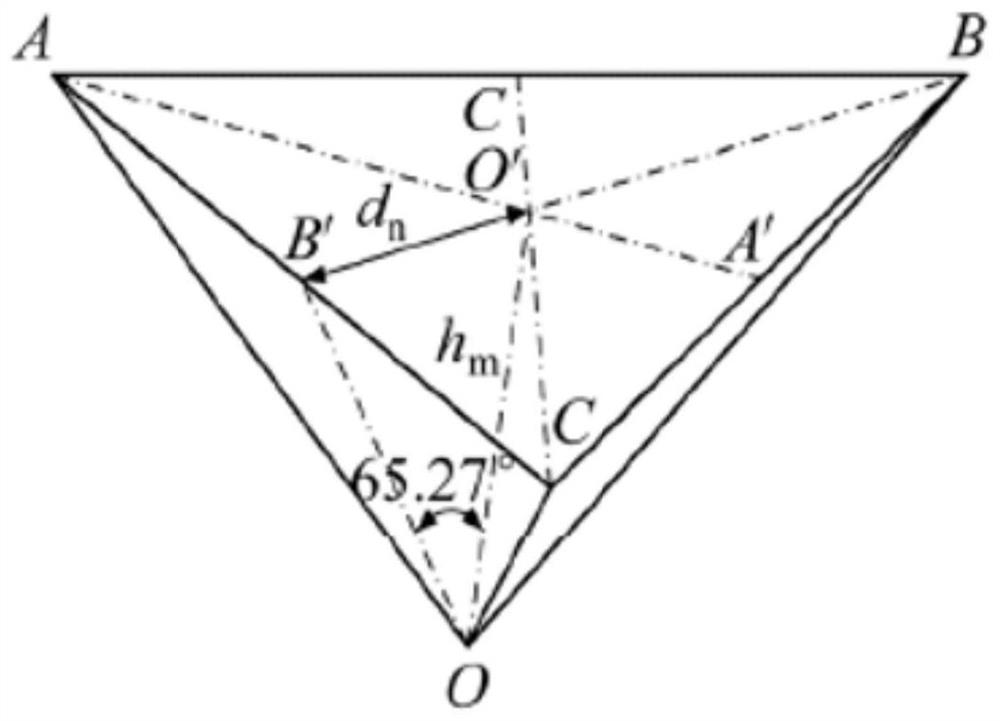

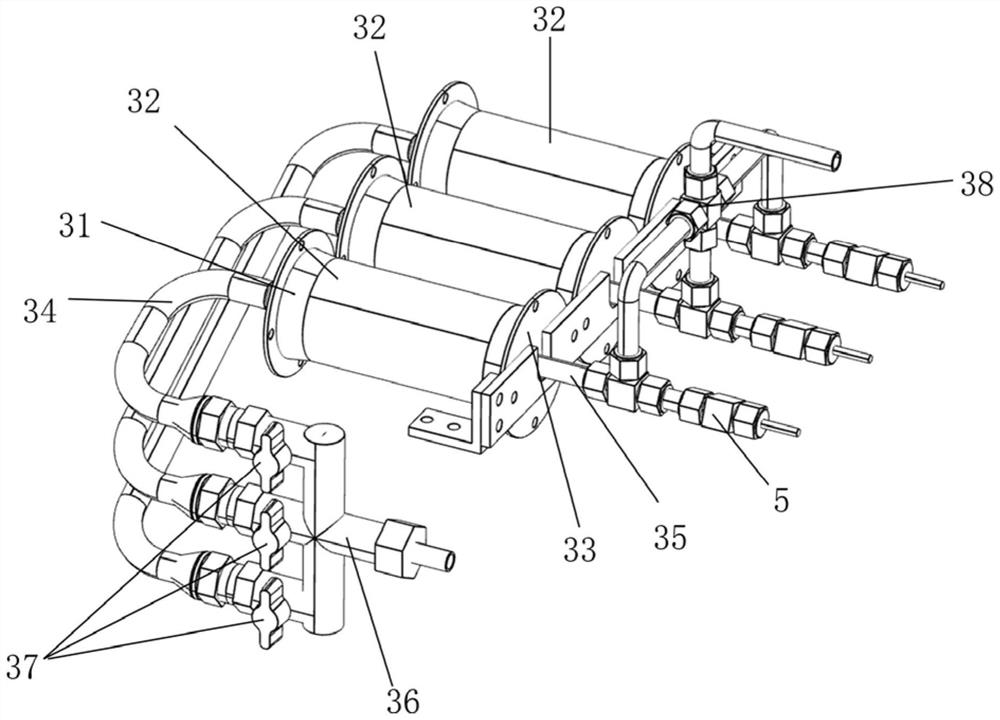

High-strain-rate nanoindentation testing device and method

PendingCN114705570AHigh speed loadingGuaranteed linear motionInvestigating material hardnessPressure generationEngineering

Owner:SHANDONG UNIV

Device for testing anti-condensation capability of material and application method

Owner:SHANGHAI KUMHO SUNNY PLASTICS +1

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap