Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Textile yarn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Textile yarn tensioning, adjusting and conveying integrated system

ActiveCN113148766AGuaranteed stabilityCause deadlockMechanical cleaningPressure cleaningTextile yarnStructural engineering

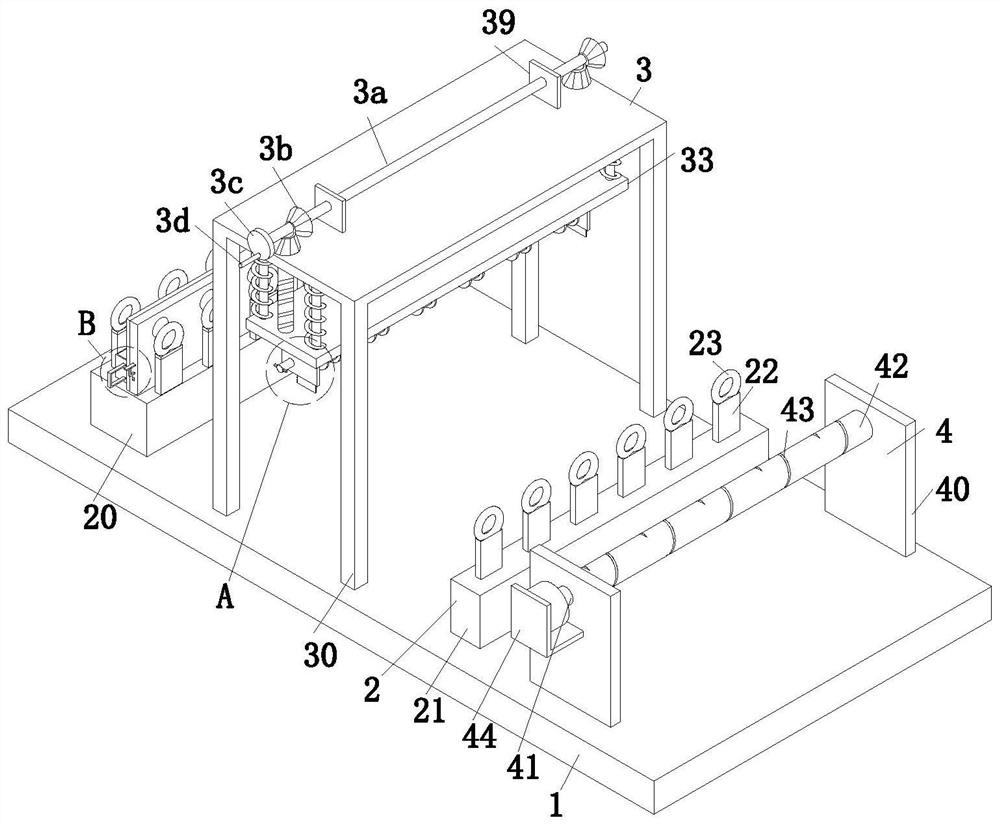

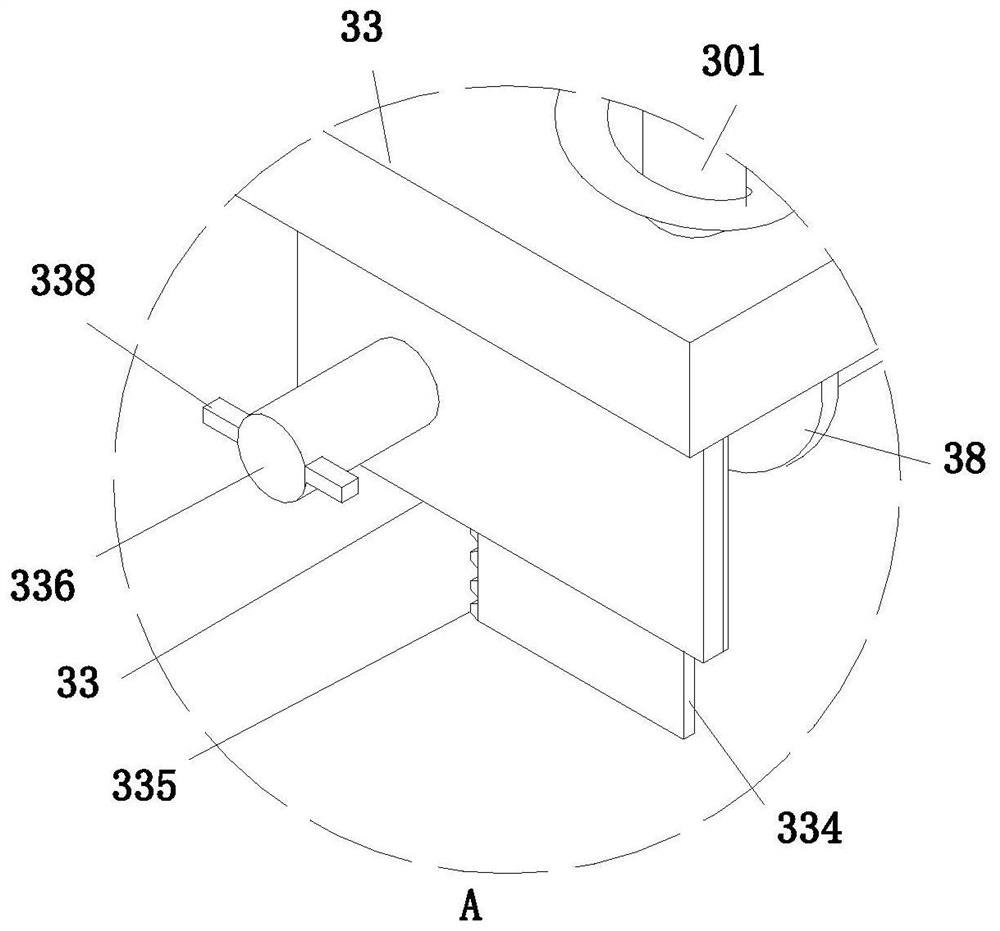

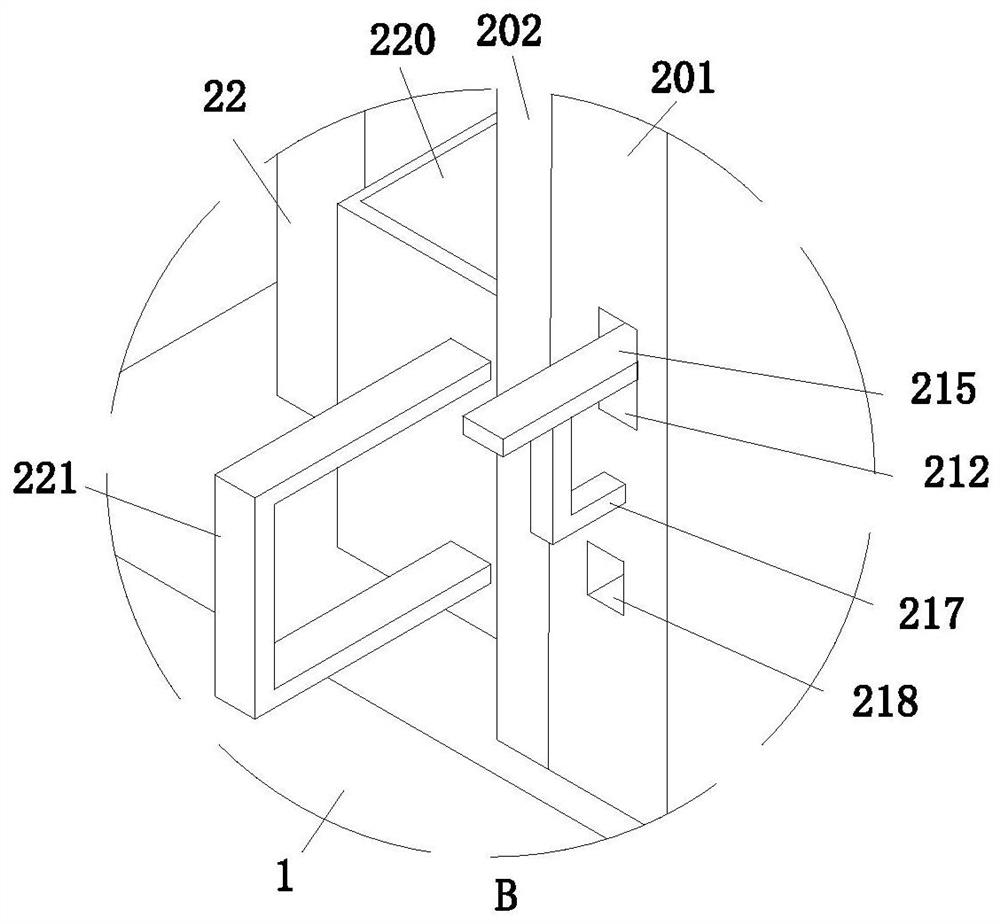

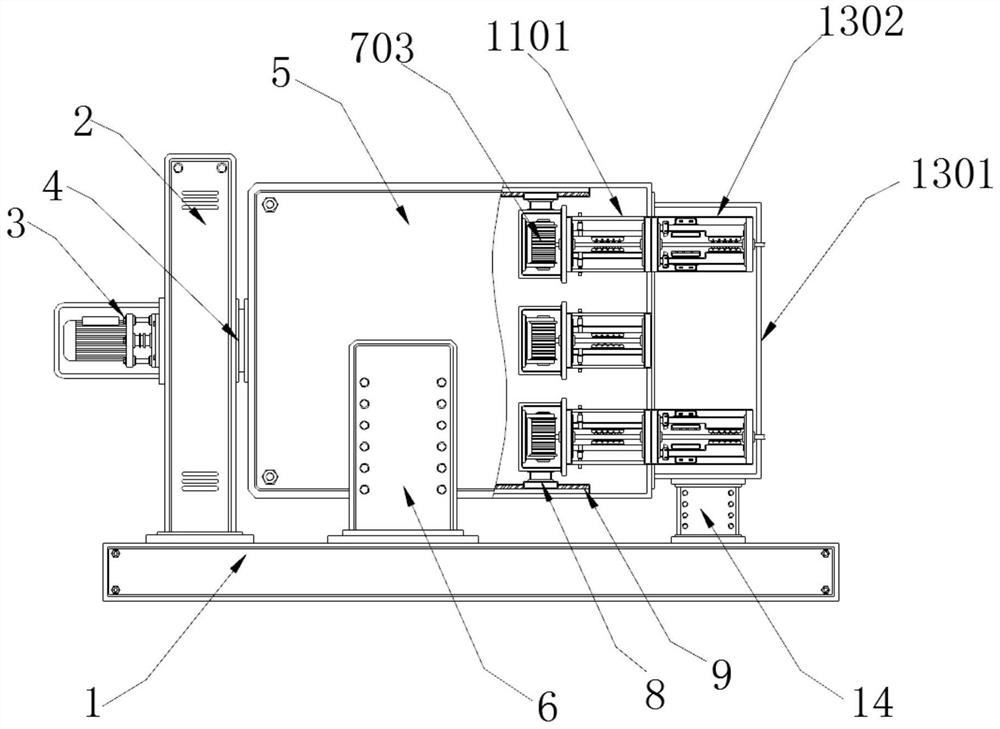

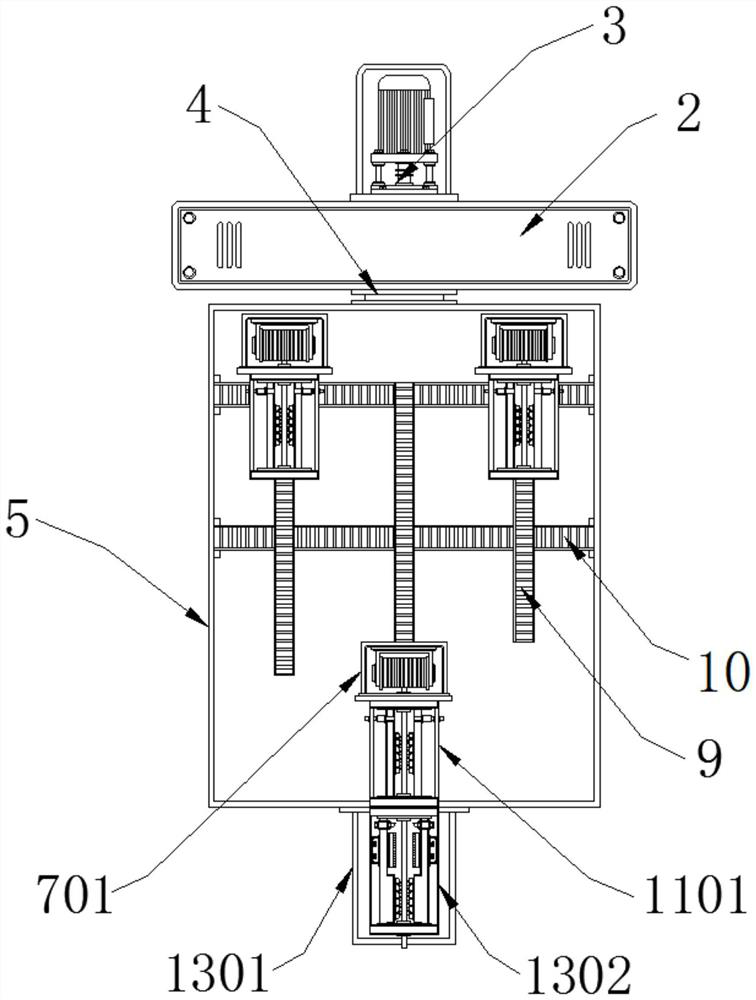

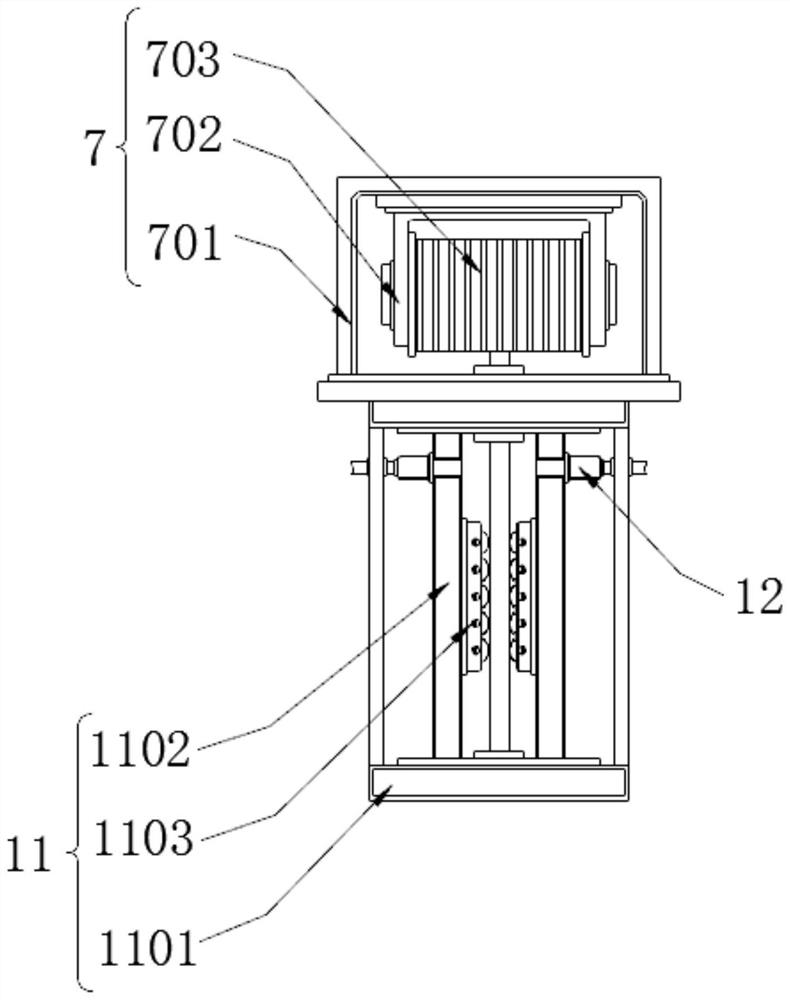

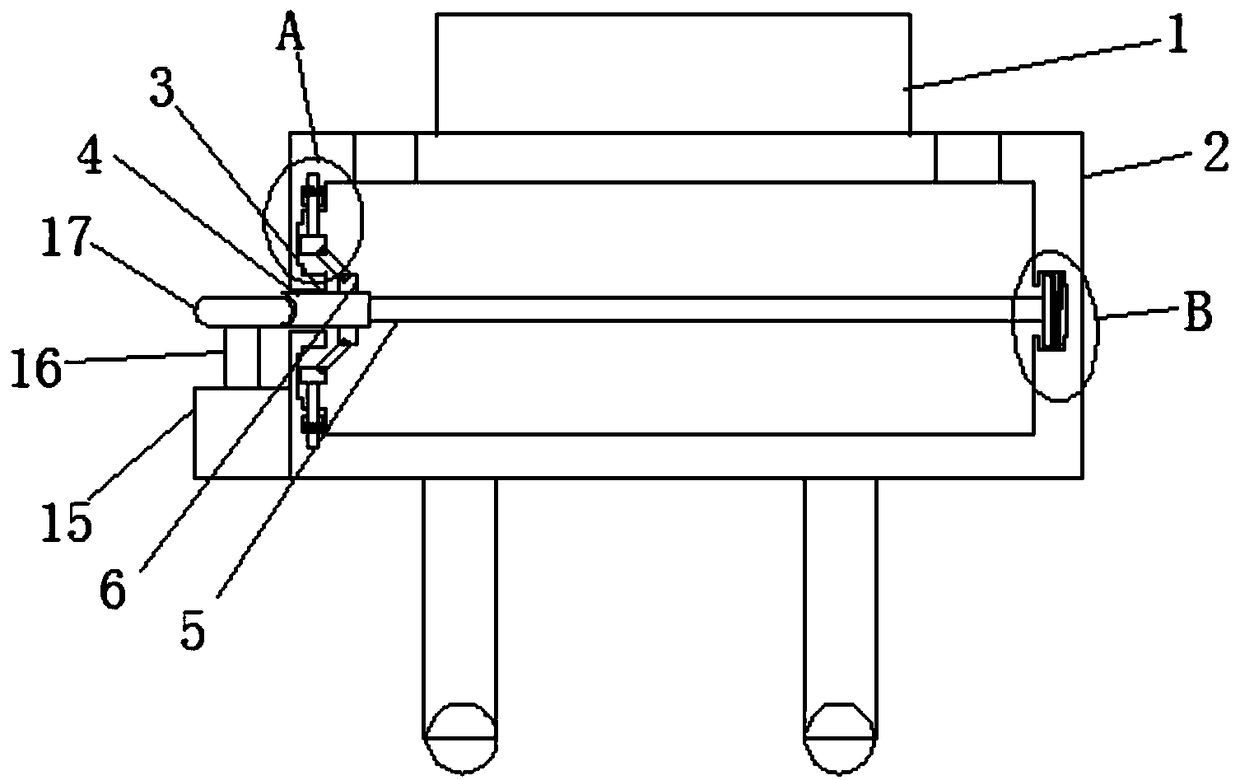

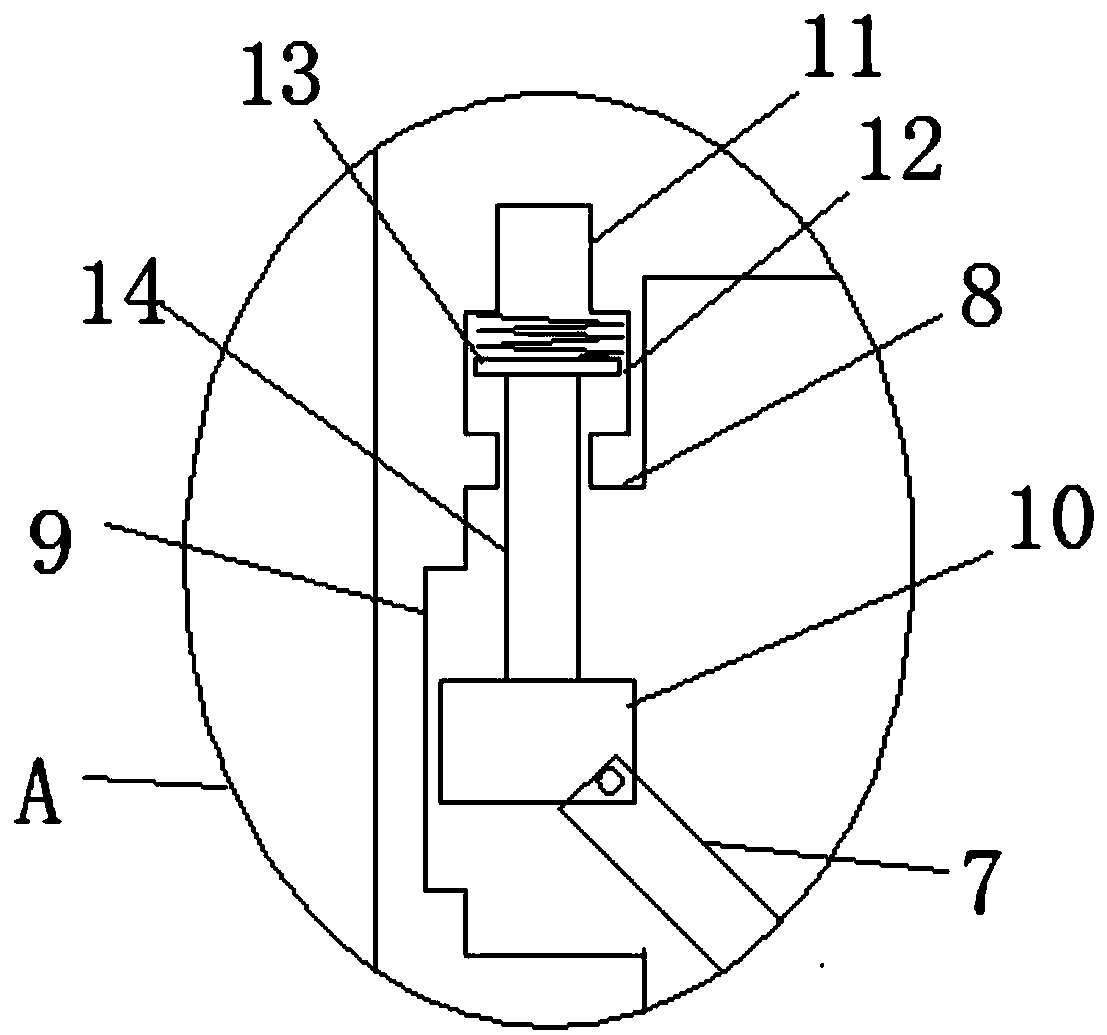

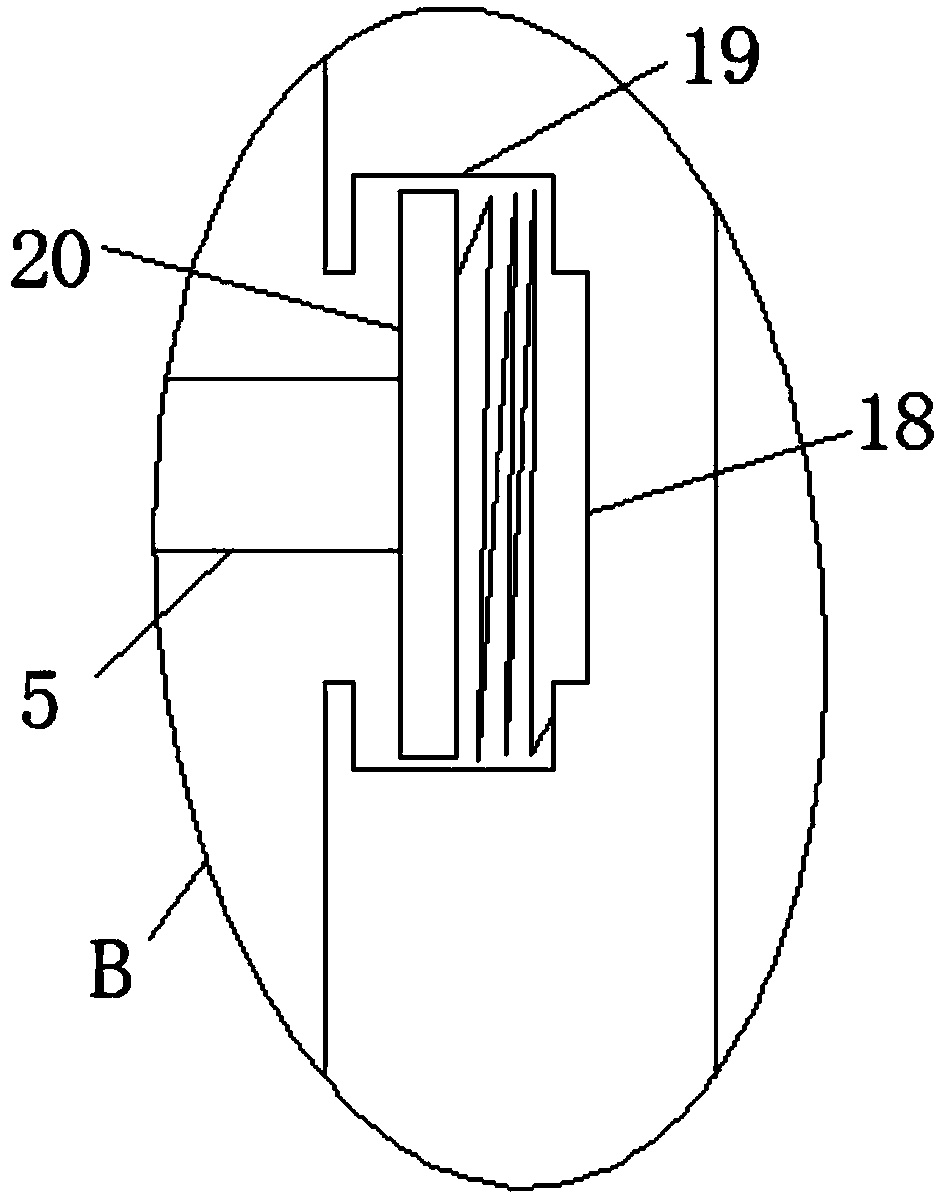

The invention relates to a textile yarn tensioning, adjusting and conveying integrated system. The textile yarn tensioning, adjusting and conveying integrated system comprises a workbench, a sleeving mechanism, a tensioning mechanism and a conveying mechanism, wherein the sleeving mechanism and the tensioning mechanism are installed on the upper end face of the workbench, and the conveying mechanism is arranged at the right side of the sleeving mechanism. According to the textile yarn tensioning, adjusting and conveying integrated system, the adopted tensioning mechanism drives yarns on rolling cylinders to move upwards to conduct primary tensioning, and then lifting plates move to enable the rolling cylinders to drive the yarns to conduct secondary fine adjustment tensioning, so that it is guaranteed that the yarns are not broken due to too large tensioning force; meanwhile, the yarns are tensioned, so that the stability of the yarns in the conveying process is guaranteed, and the phenomenon of conveying deviation or conveying failure caused by yarn looseness is avoided; and meanwhile, the conveying mechanism can convey the yarns in the corresponding grooves, so that the phenomenon that because the yarns are wound together, hard knots are caused is avoided.

Owner:山东杰瑞纺织科技有限公司

Line position-adjustable yarn conveying equipment for large-scale spinning

Owner:JIHUA 3509 TEXTILE

Convenient-to-move textile yarn machinery equipment

InactiveCN109183333AGuaranteed use environmentEasy to moveTextile treatment machine arrangementsTextile yarnWastewater

Owner:安吉倍豪纺织有限公司

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap