Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12 results about "Troubleshooting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Troubleshooting is a form of problem solving, often applied to repair failed products or processes on a machine or a system. It is a logical, systematic search for the source of a problem in order to solve it, and make the product or process operational again. Troubleshooting is needed to identify the symptoms. Determining the most likely cause is a process of elimination—eliminating potential causes of a problem. Finally, troubleshooting requires confirmation that the solution restores the product or process to its working state.

Monitoring and controlling the operation of devices in a distributed network of broadcast devices

ActiveUS20110206136A1Picture reproducers using cathode ray tubesPicture reproducers with optical-mechanical scanningTest engineerBroadcasting

The invention relates to a system and method for monitoring and controlling the operation of devices in a distributed network of broadcast devices, such as Set Top Boxes (STBs). Such devices typically require periodic updates as new versions of operating software is developed. However, it is not possible to guarantee that all devices that have received an updated software version are able to operate correctly. The system initiates a test for a STB and monitors in real time the state of the STB as the software download occurs. The state of the STB is reported to a system controller and the results are output to a test engineer. Other devices in the broadcast network can be controlled by the controller and various troubleshooting or operational tests performed.

Owner:DISH TECH LLC

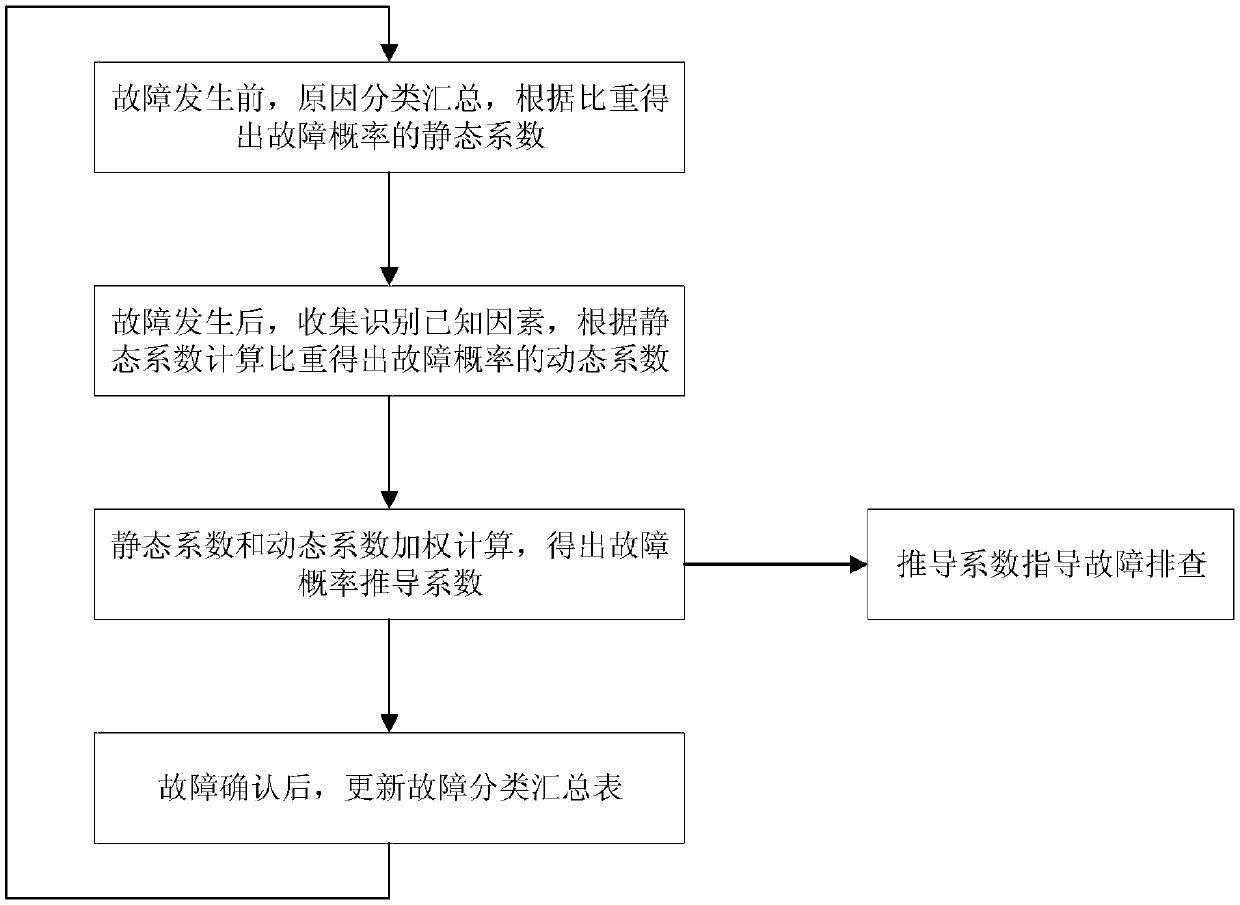

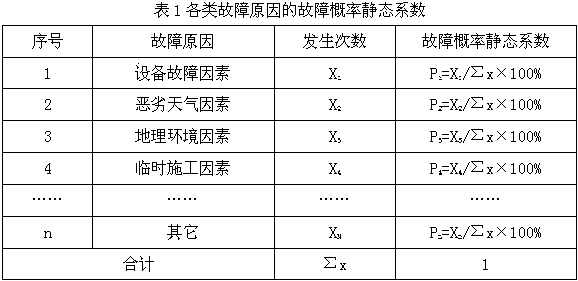

Distribution line fault cause comprehensive probability analysis method

ActiveCN109521327ARealize self-learningAddressing lack of empirical evidenceFault location by conductor typesAnalysis methodComputer science

Owner:GUIZHOU POWER GRID CO LTD

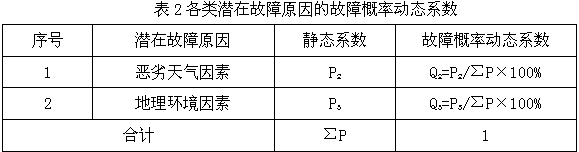

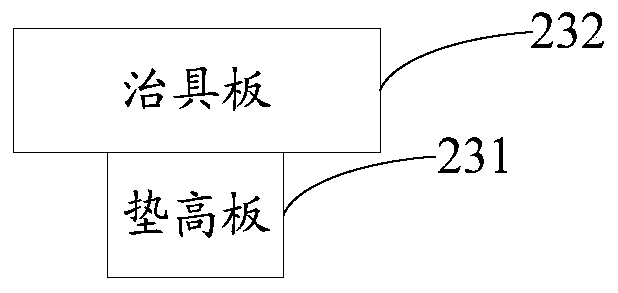

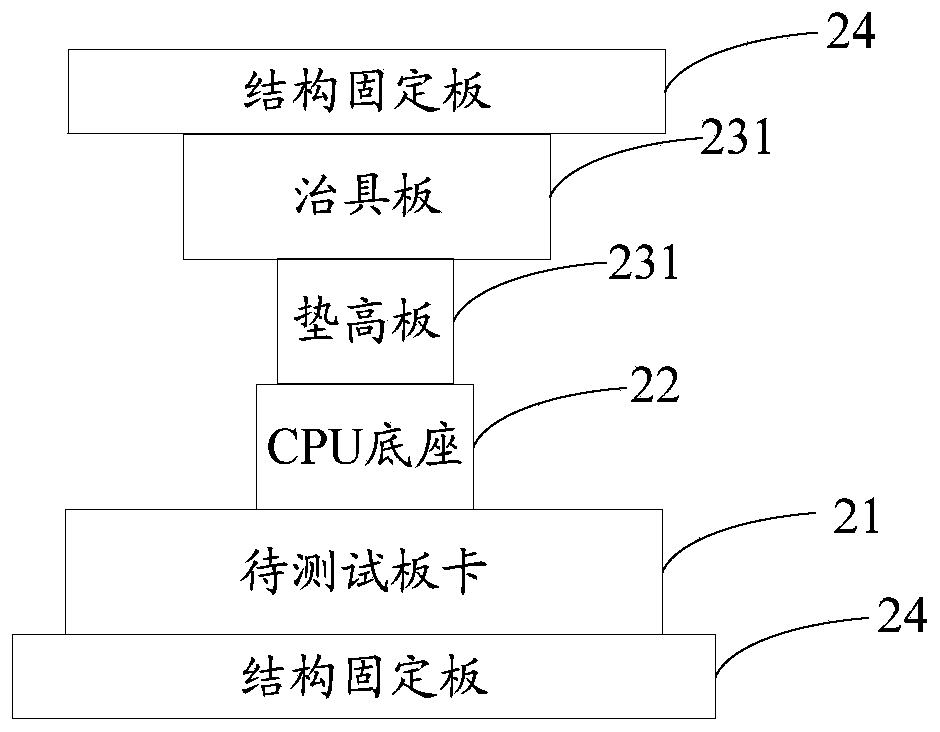

Impedance test structure, device and method

InactiveCN110568340AImpedance test implementationEasy to checkResistance/reactance/impedencePrinted circuit testingTest equipmentElectrical and Electronics engineering

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

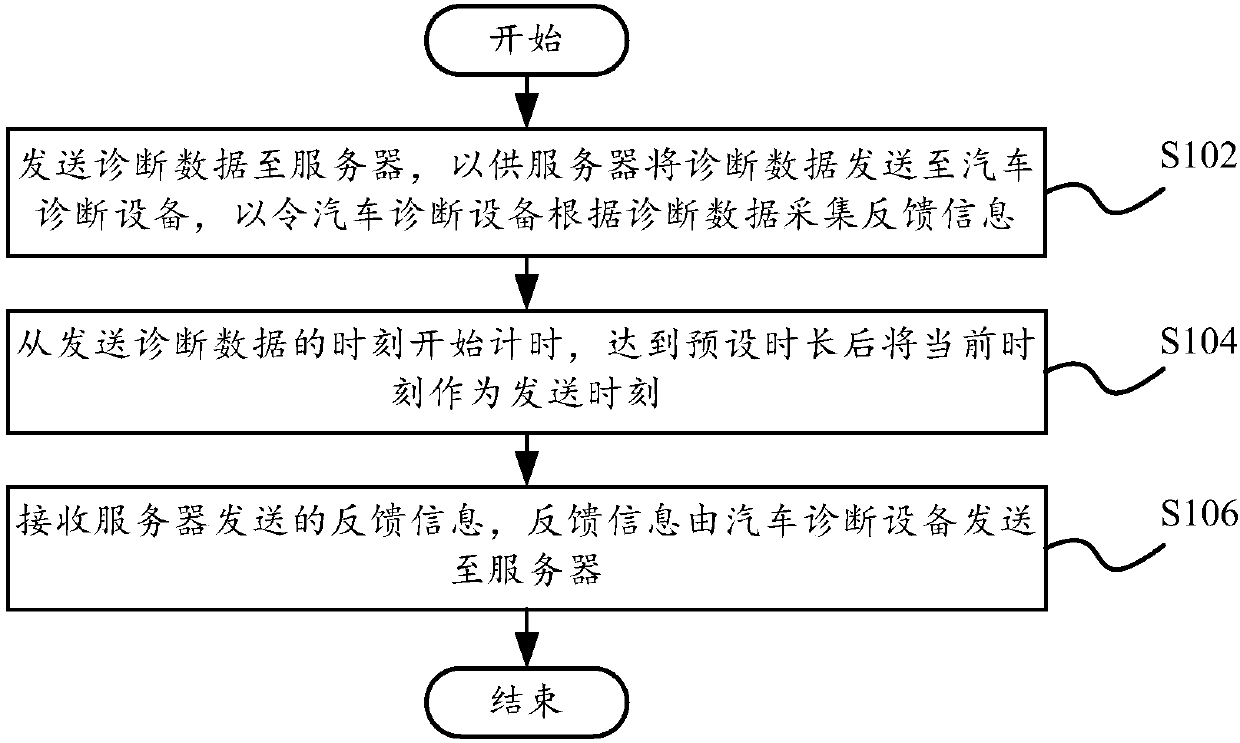

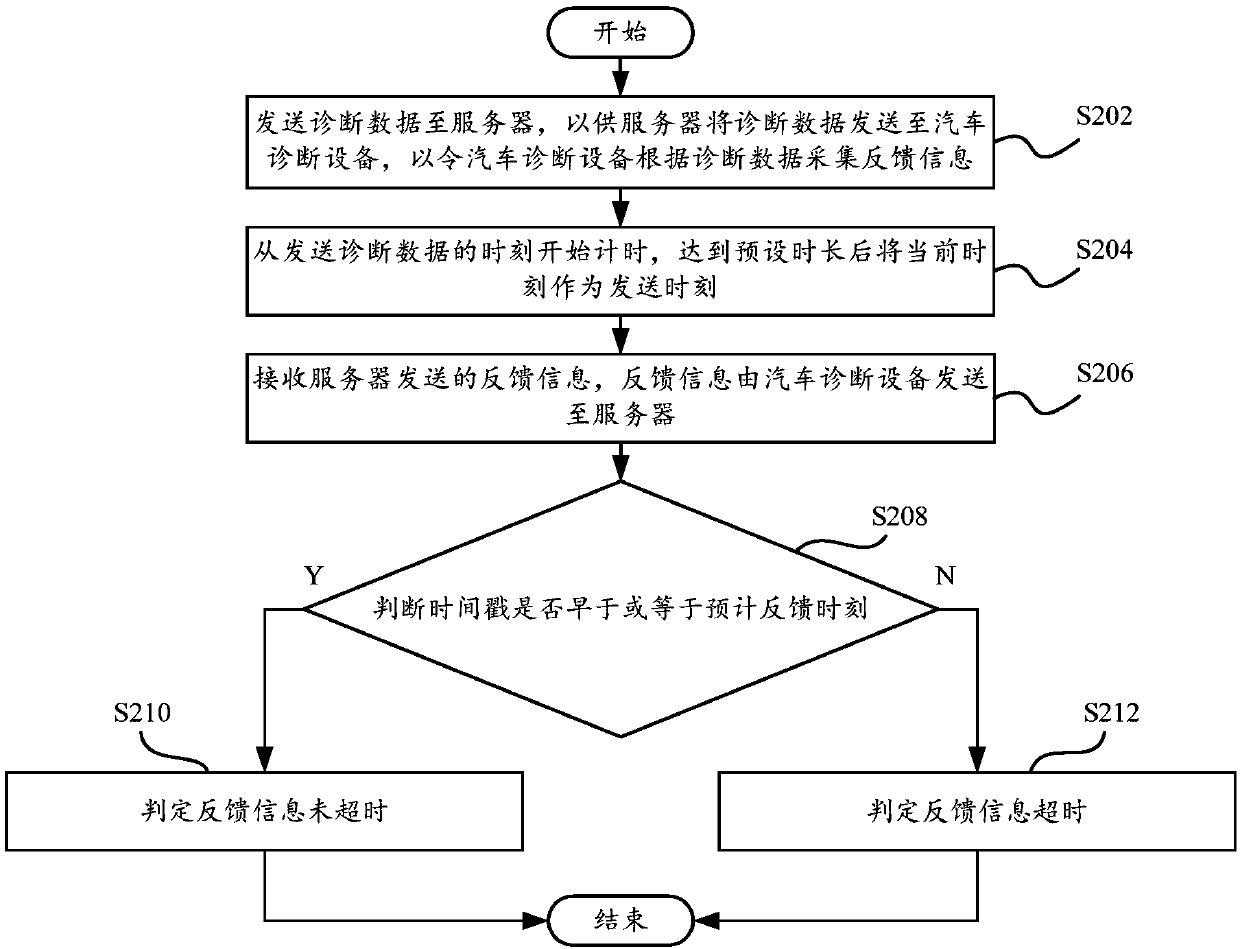

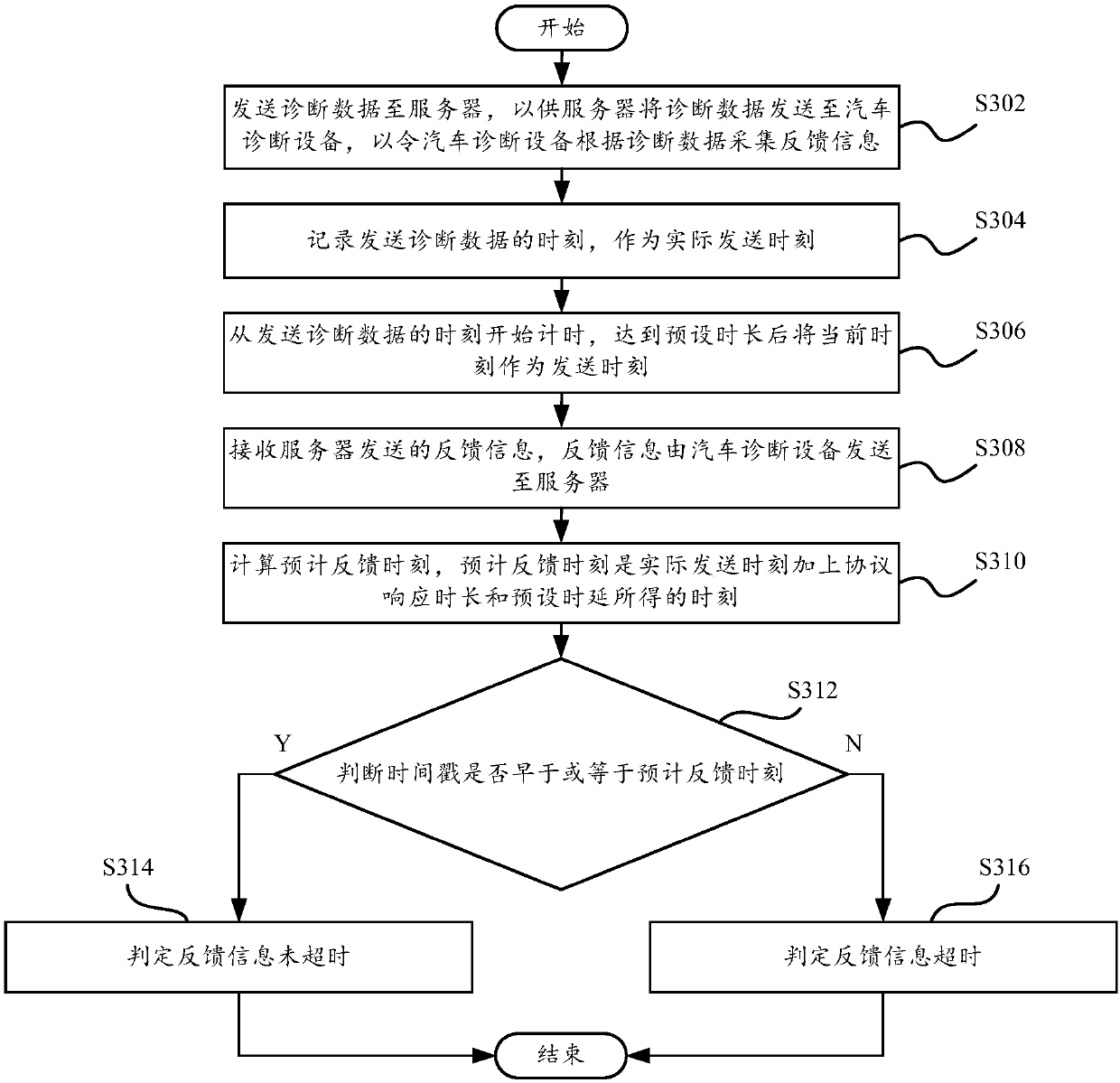

Automobile bus communication method and system, remote terminal and automobile diagnosis device

ActiveCN109873733ABus networksDiagnostic dataTroubleshooting

Owner:SHANGHAI OUFEI INTELLIGNET VEHICLE INTERNET TECH CO LTD

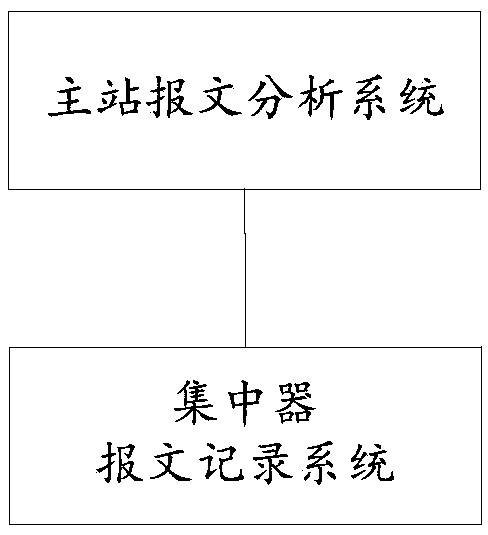

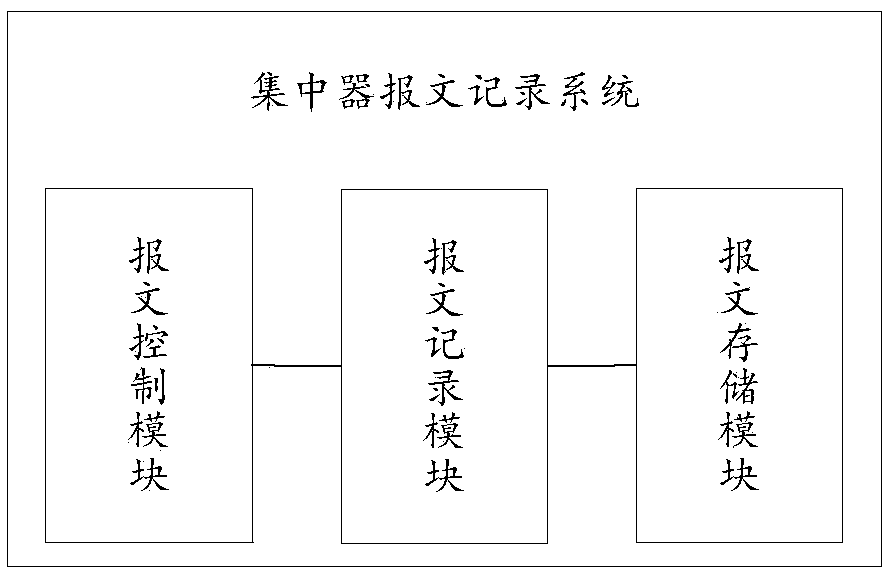

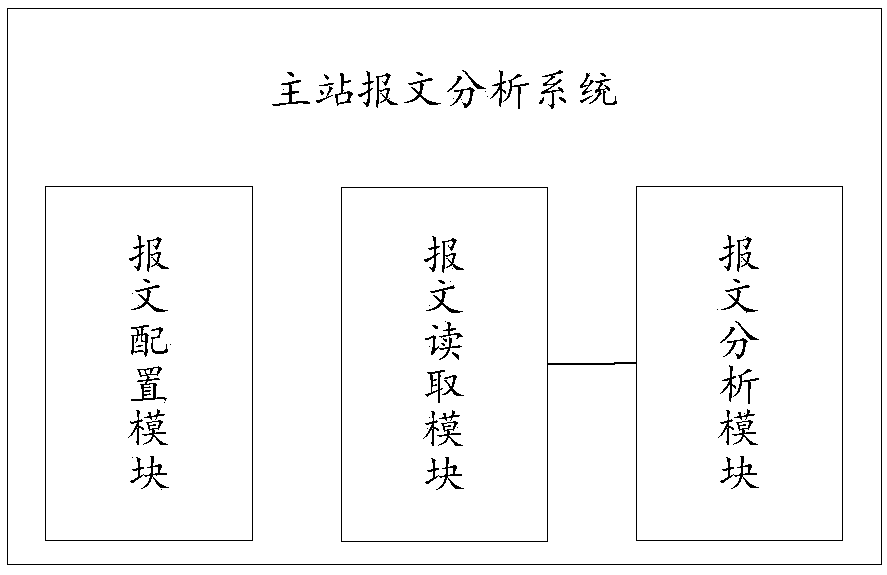

A Message Analysis and Processing System Based on Water, Electricity, Gas and Heat Concentrators

InactiveCN109088798AUtility meters data arrangementsData switching networksTroubleshootingElectricity

Owner:WUHAN SAN FRAN ELECTRONICS CO LTD

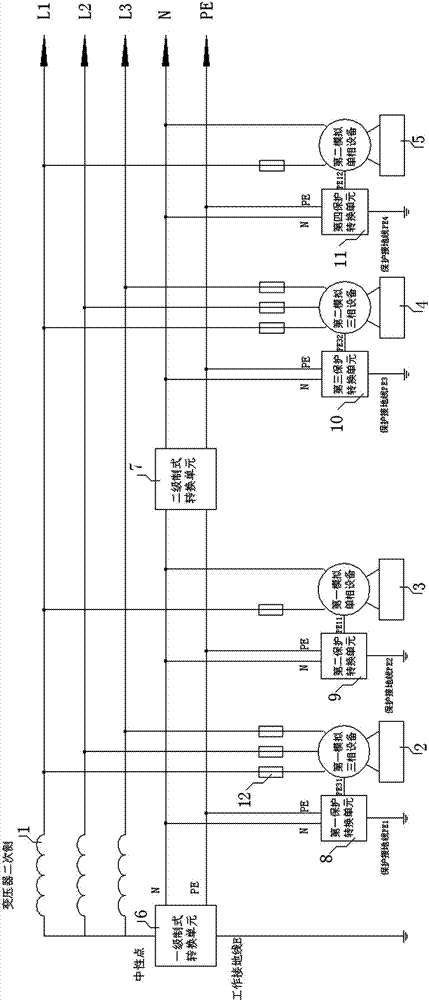

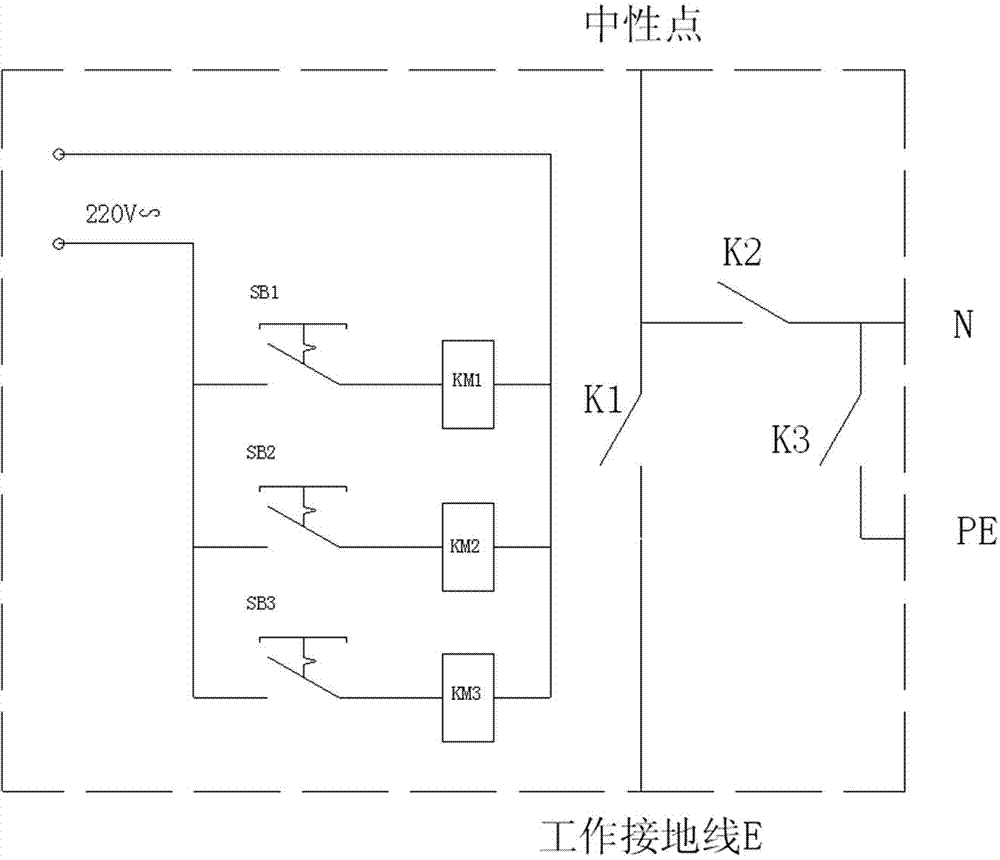

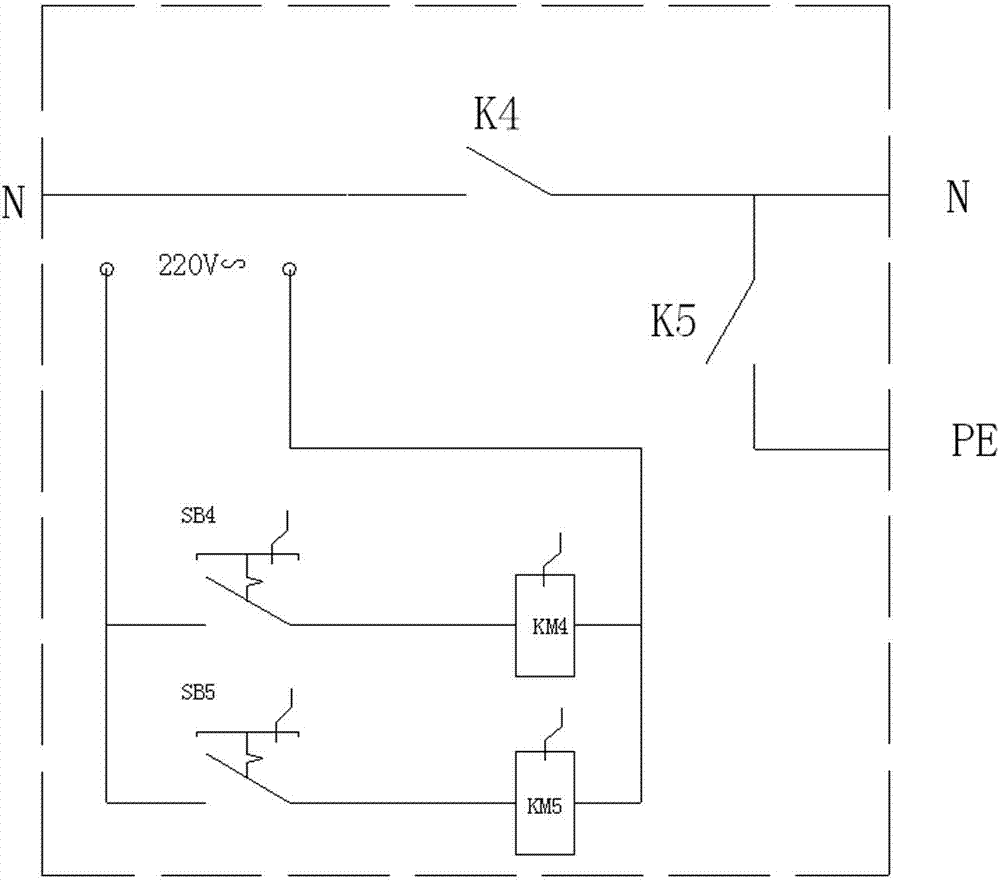

Device for converting analog distribution network system

Owner:STATE GRID CHONGQING ELECTRIC POWER COMPANY SKILLTRAINING CENT

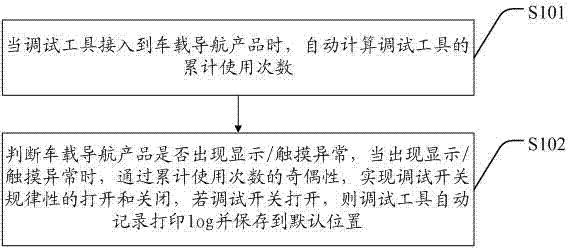

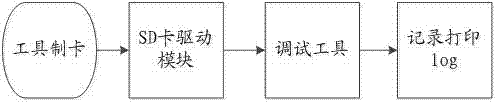

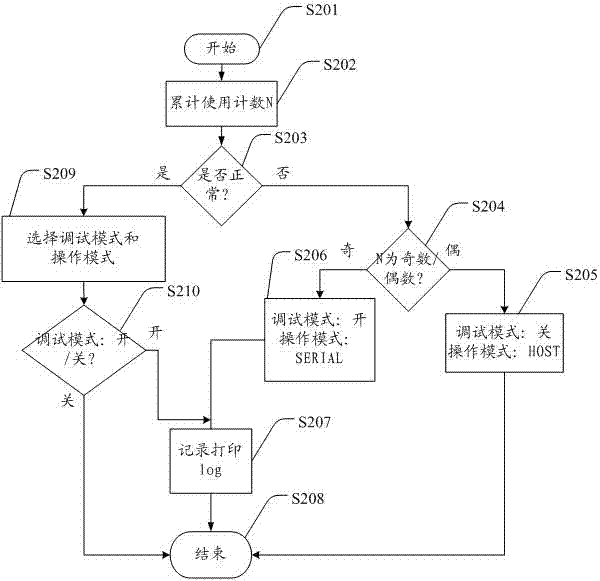

Debugging tool and debugging method based on vehicle-mounted navigation product

ActiveCN104729536ASolve product problemsSave R&D and after-sales costsMeasurement devicesProduct ProblemTroubleshooting

The invention discloses a debugging tool and a debugging method based on a vehicle-mounted navigation product. The method comprises the following steps: A, automatically calculating the cumulative application times of the debugging tool when the debugging tool is accessed to the vehicle-mounted navigation product; and B, judging whether the vehicle-mounted navigation product is abnormal in display / touch or not, facilitating the regular on-off of a debugging switch by virtue of the parity of the cumulative application times if the display / touch is abnormal, automatically recording and printing log and storing the log to a default location by virtue of the debugging tool if the debugging switch is turned on. By adopting the debugging tool and the debugging method, abnormal logs can be efficiently and conveniently captured by the non-technical personnel, and the technical personnel also can be assisted to turn on the debugging switch and change the operation mode, so that the product problem can be solved in time, the research and development cost and the after-sales cost can be saved, trouble-shooting is facilitated, and the research and development efficiency and the efficiency for solving the after-sales problem can be improved.

Owner:广东卡仕达电子科技有限公司

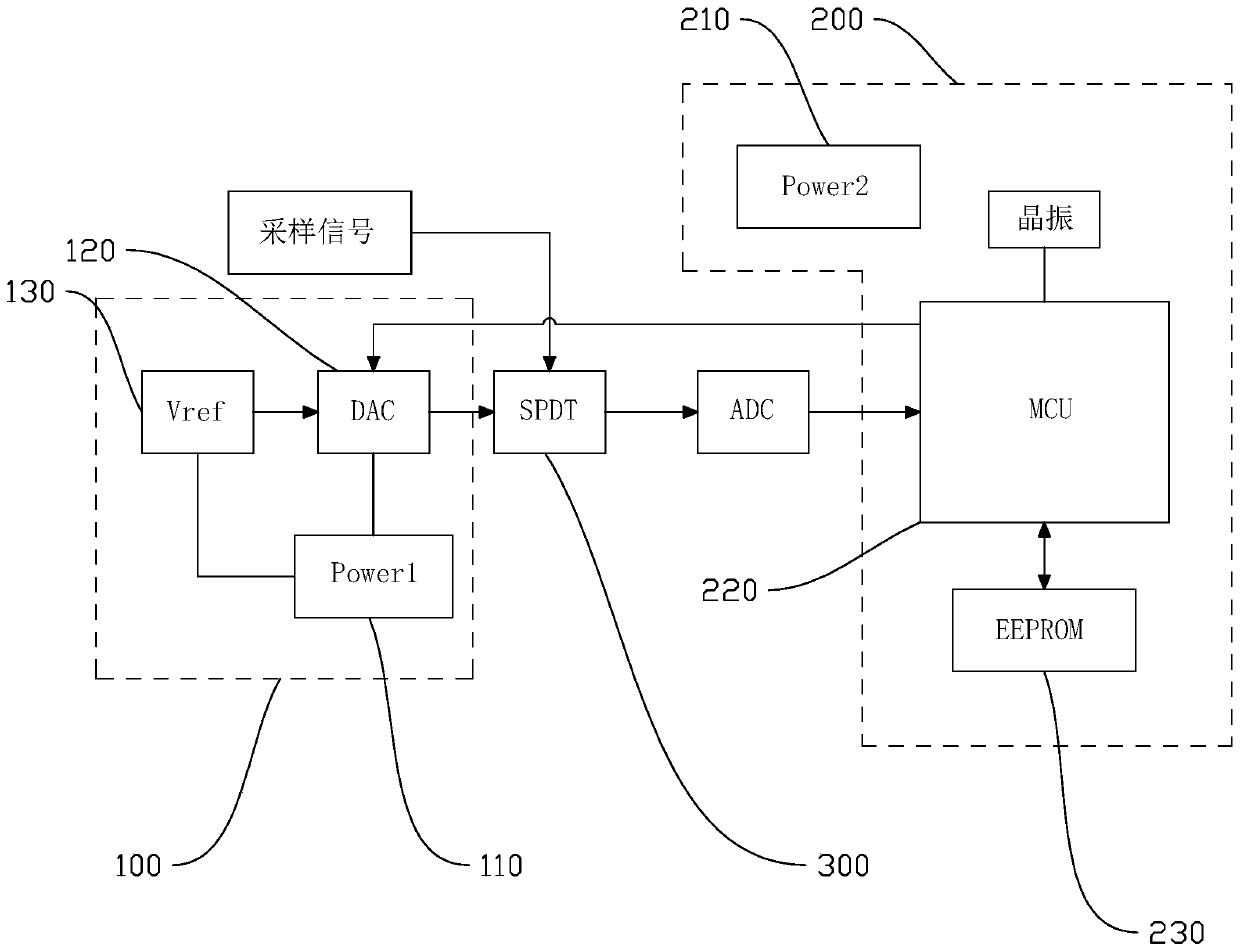

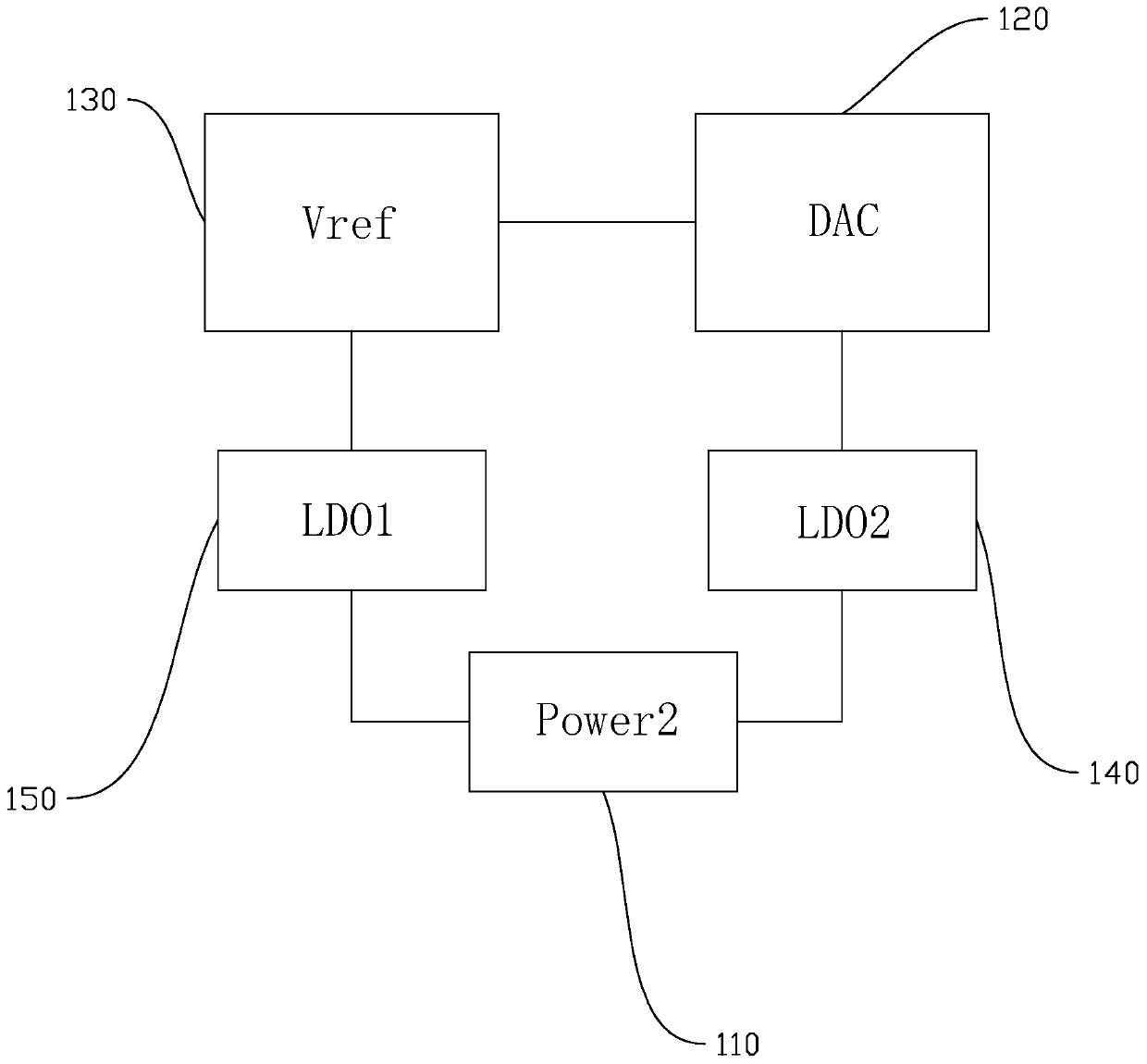

Analog-to-digital converter calibration system and method

PendingCN111010180AAchieve calibrationEasy to find outAnalogue/digital conversion calibration/testingConvertersSoftware engineering

Owner:XTR SOLUTIONS

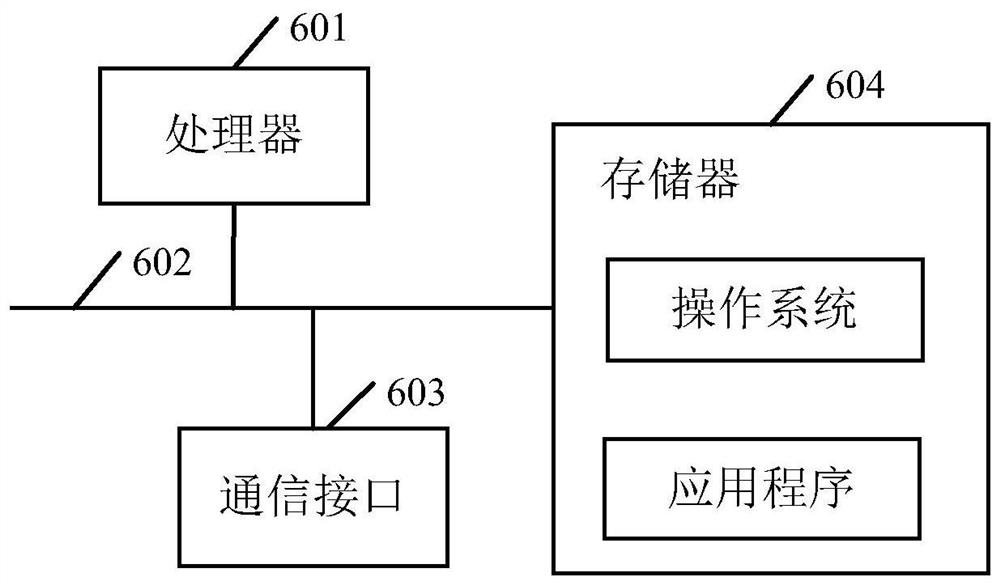

Method for engineering equipment, processor and server

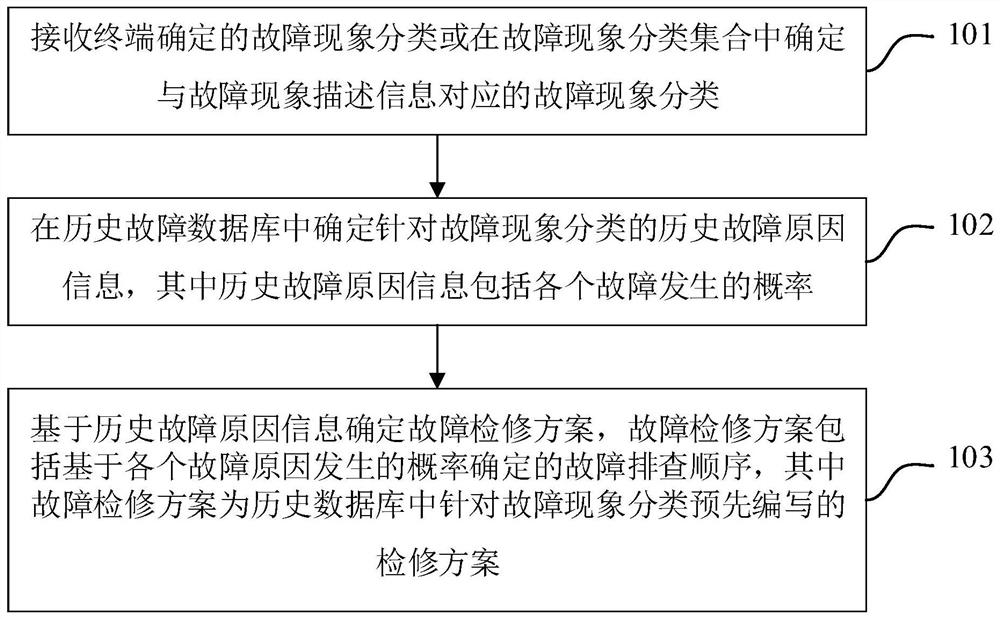

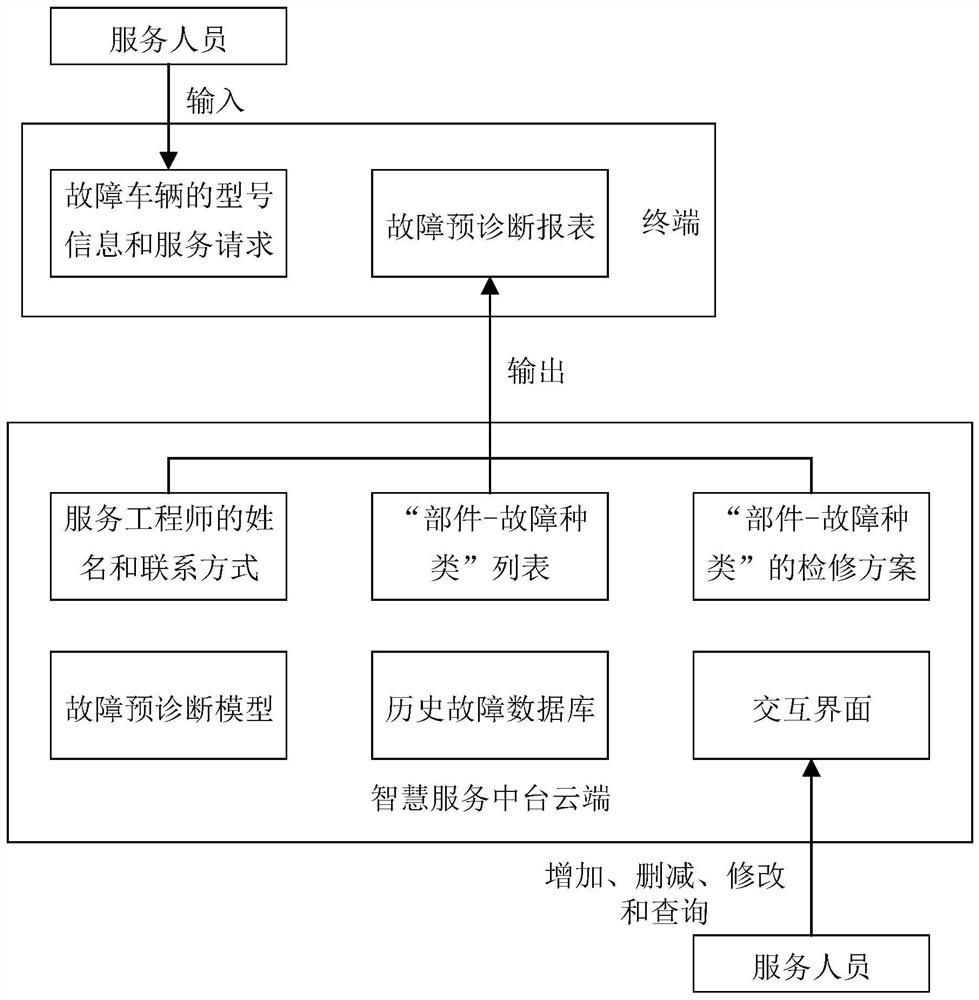

PendingCN114357262AImprove work efficiencyImprove reliabilityOther databases clustering/classificationTroubleshootingOccurrence probability

The invention relates to the technical field of engineering machinery, and discloses a method for engineering equipment, a processor and a server. The method comprises the following steps: receiving a fault phenomenon classification determined by a terminal or determining a fault phenomenon classification corresponding to fault phenomenon description information in a fault phenomenon classification set; historical fault reason information for fault phenomenon classification is determined in a historical fault database, and the historical fault reason information comprises the occurrence probability of each fault reason; and determining a fault maintenance scheme based on the historical fault reason information, the fault maintenance scheme comprising a fault troubleshooting sequence determined based on the probability of occurrence of each fault reason, and the fault maintenance scheme being a maintenance scheme pre-compiled for fault phenomenon classification in a historical fault database. According to the invention, a fault point can be rapidly positioned for service personnel, an optimal troubleshooting step is provided, and the working efficiency of field service personnel and the reliability of fault maintenance are improved.

Owner:ZOOMLION HEAVY IND CO LTD

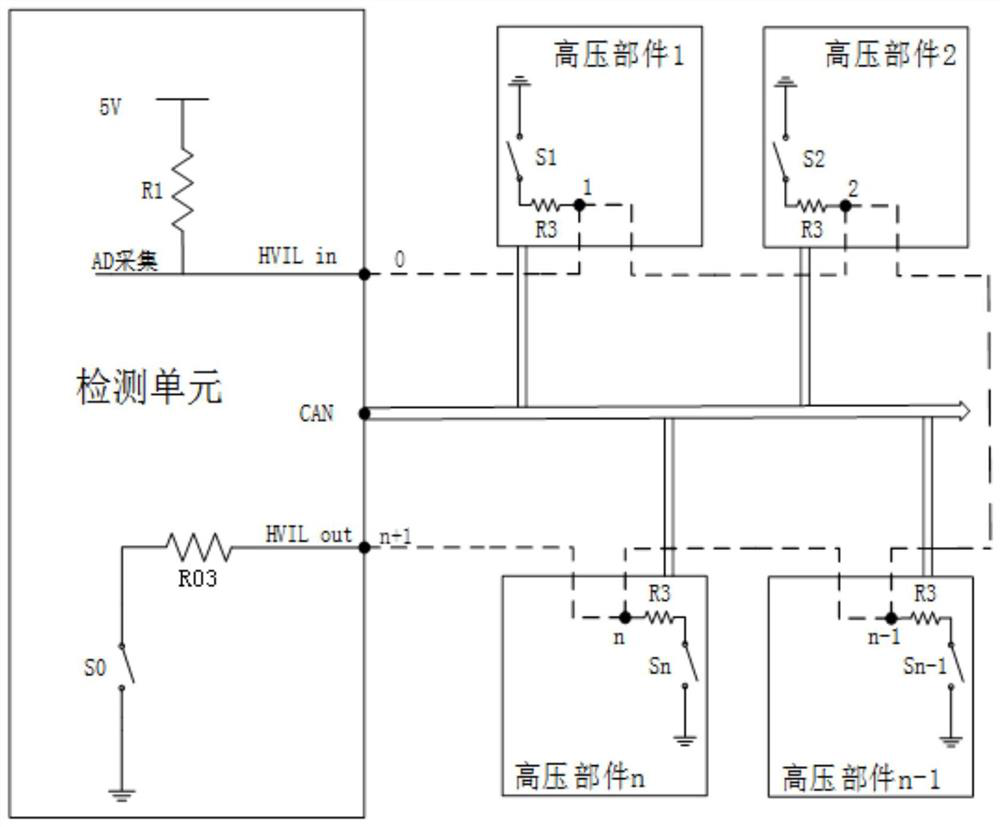

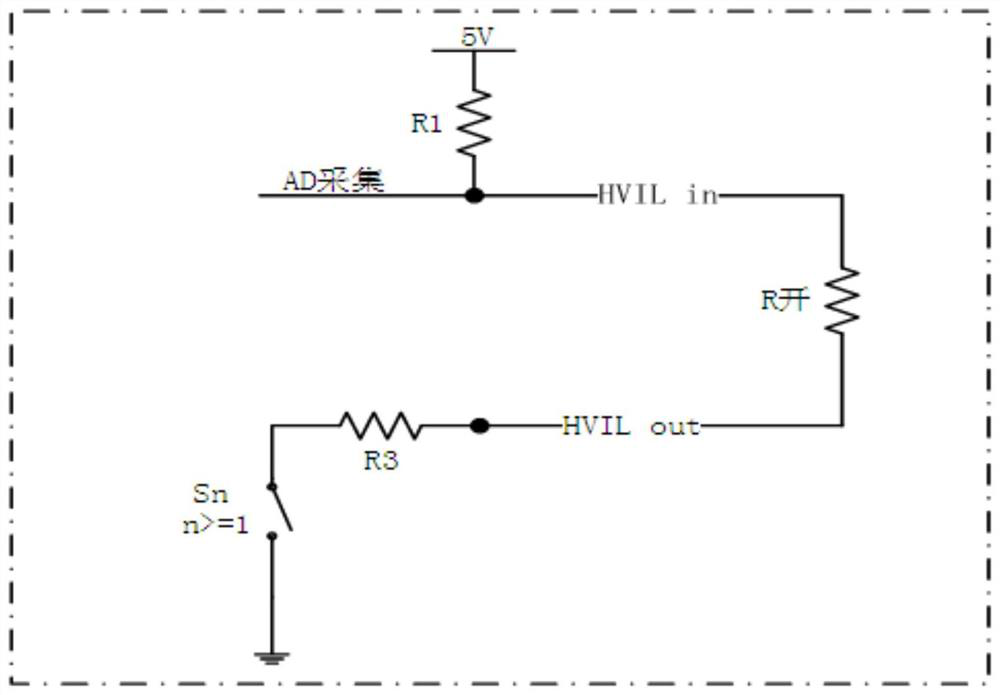

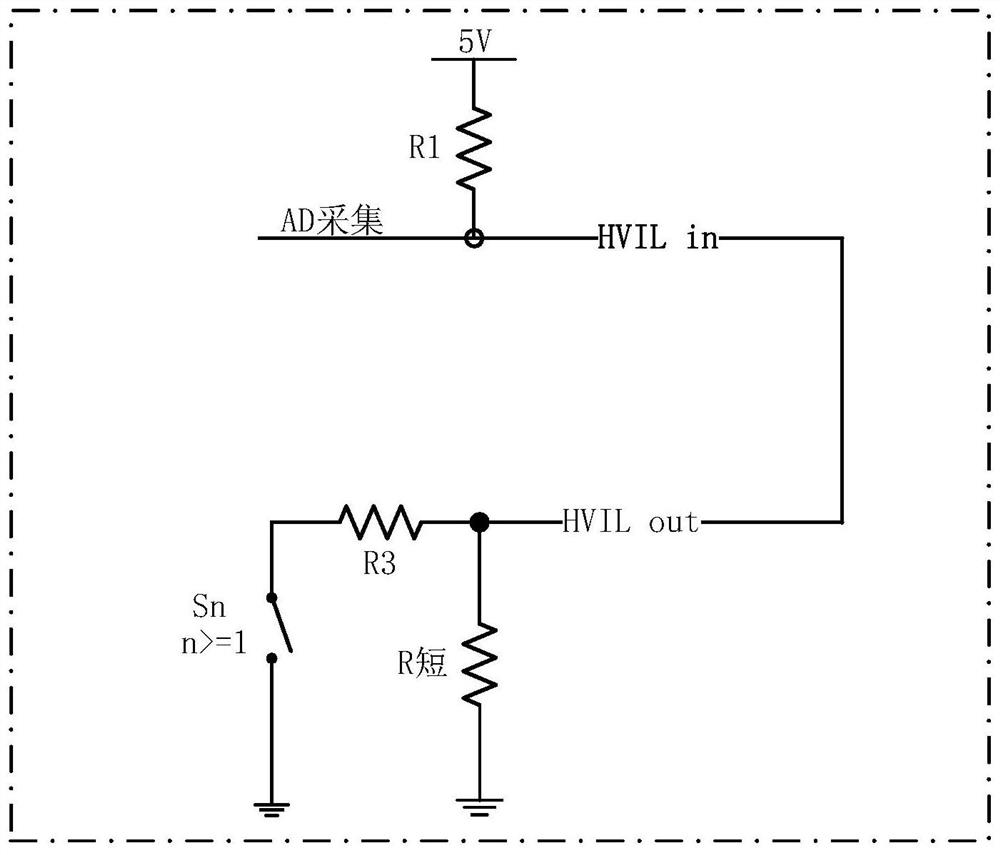

High-voltage interlocking detection circuit and fault detection method

ActiveCN113219376AEffective detection of early interlock failures due to poor contactEarly interlock failure detection for poor contactElectric connection testingContinuity testingTroubleshootingEngineering

According to a high-voltage interlocking detection circuit and a fault detection method disclosed by the invention, an open-circuit fault voltage threshold and a short-circuit fault voltage threshold are preset, and the connection state of the whole high-voltage loop can be detected in real time by controlling the on-off and step-by-step detection of the controllable switch in the control detection switch circuit, the early interlocking fault of poor contact of the high-voltage component can be effectively detected, and the high-voltage component is prevented from working with faults under the condition of poor contact. Due to the independent detection of each control detection switch circuit and the high-voltage component connected with the control detection switch circuit, the fault occurrence point of the high-voltage interlocking loop can be effectively detected, the manual troubleshooting of each section of line and each high-voltage component is avoided, and the troubleshooting efficiency is effectively improved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

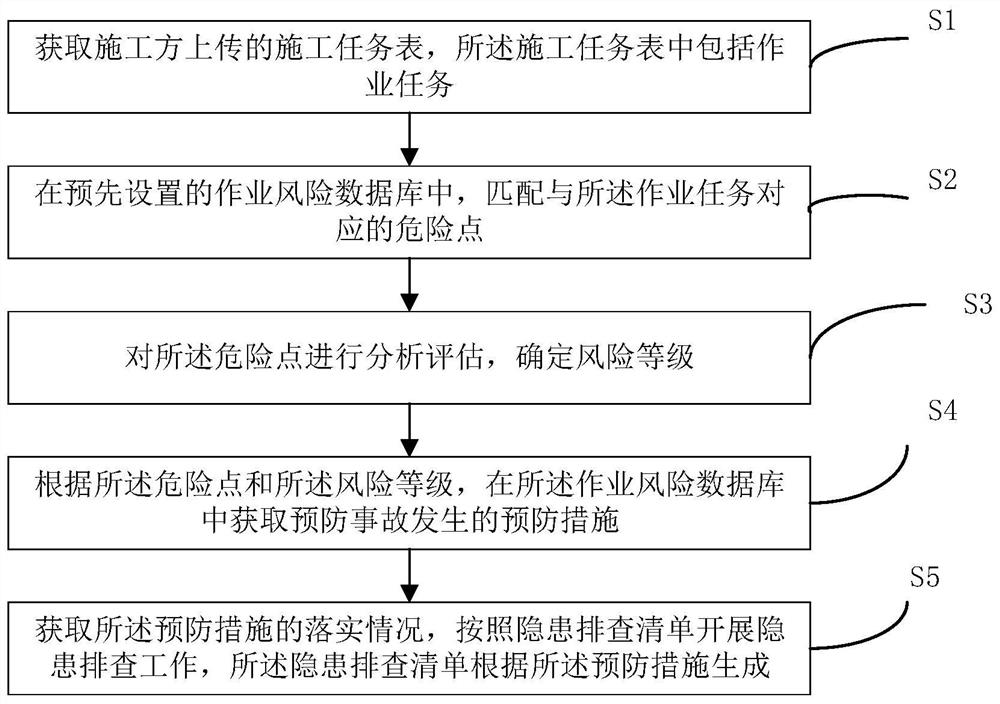

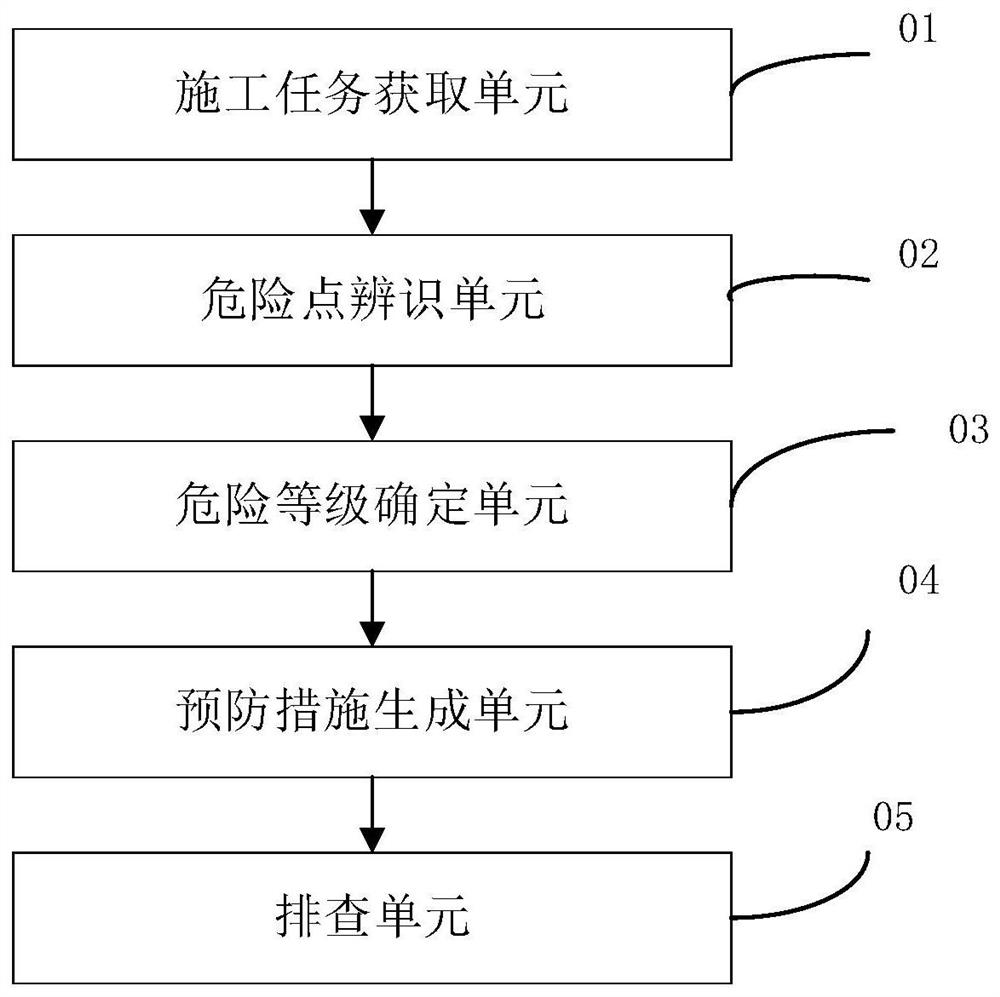

Electric power construction site safety risk management and control method, device and platform

The invention provides an electric power construction site safety risk management and control method comprising the following steps: acquiring a construction task table uploaded by a construction unit, wherein the construction task table comprises operation tasks, matching a dangerous point corresponding to the operation task in a preset operation risk database, analyzing and evaluating the dangerous point, and determining a risk level, acquiring preventive measures for preventing accidents from happening in the operation risk database, and obtaining the implementation condition of the preventive measures, and carrying out hidden danger troubleshooting work according to a hidden danger troubleshooting list. According to the safety risk management and control method for the electric power construction site in the scheme, dangerous points in a construction operation task can be identified through the operation risk database, so that prevention measures for preventing dangerous accidentsare obtained and serve as a first defense line for safety management, in addition, troubleshooting is carried out according to the implementation condition of prevention measures, and the method serves as a second defense line of safety management, thereby enabling the risk of a power construction site to be effectively controlled, and reducing the occurrence of accidents.

Owner:华能洋浦热电有限公司 +1

Electrical fault troubleshooting method

PendingCN111723951AGuarantee normal productionResourcesManufacturing computing systemsElectrical malfunctionPower equipment

Owner:CHINA TOBACCO GUIZHOU IND

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap