Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3 results about "Vaporizer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A vaporizer or vaporiser, colloquially known as a vape, is a device used to vaporize substances for inhalation. Plant substances can be used, commonly cannabis, tobacco, or other herbs or blends of essential oil. However, they can also be filled with a combination propylene glycol, glycerin, and drugs such as nicotine (e.g. extract from tobacco) or tetrahydrocannabinol as a liquid solution.

Vaporiser insert, vaporiser-tank unit for an inhaler, inhaler, and method for production

InactiveUS20190328039A1Easy to assembleIntegrated cost-effectivelyMedical devicesTobacco devicesControl signalInhalation Devices

A vaporiser insert for an inhaler comprises at least one electrical vaporiser for vaporising liquid fed to the vaporiser, and electrical contacts for making electrical contact with the vaporiser insert for supplying with electrical energy and / or for receiving control signals for the vaporiser. The vaporiser insert has a base part with opposingly arranged faces and a jacket side between the faces arranged around at least one flow channel through which vapour can flow, wherein at least one liquid opening for feeding vaporisable liquid from the outside into the vaporiser insert to the vaporiser is arranged on the jacket side of the base part.

Owner:HAUNI MASCHINENBAU AG

Liquid evaporation, concentration and drying integrated treatment method

InactiveCN111544910ALow moisture content in solidsNot easy to boardEvaporator accessoriesEngineeringMechanical engineering

Owner:广州远智能源科技有限公司

Double-effect MVR (mechanical vapor recompression) evaporator and evaporation technology thereof

ActiveCN105251228AEnsure safetyGuaranteed stabilityMultiple-effect evaporationThermodynamicsVapor–liquid separator

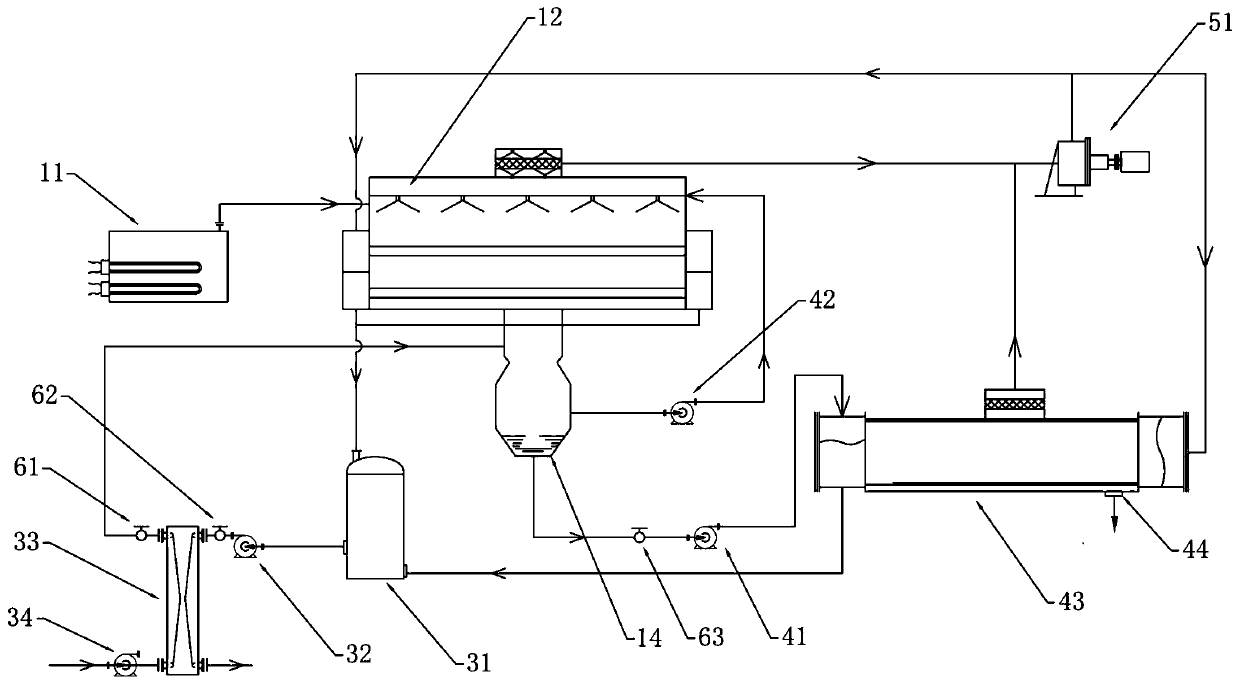

The invention discloses a double-effect MVR (mechanical vapor recompression) evaporator and an evaporation technology thereof. The double-effect MVR evaporator comprises an alcohol extract evaporation system, a water extract evaporation system and a vapor compressor, wherein the alcohol extract evaporation system is sequentially connected with the water extract evaporation system and the vapor compressor through pipelines and comprises a first-effect evaporator and a first-effect gas-liquid separator which are connected sequentially through a pipeline; the water extract evaporation system comprises a second-effect evaporator and a second-effect gas-liquid separator which are sequentially connected through a pipeline; the output end of the vapor compressor is connected with the shell pass of the first-effect evaporator of the alcohol extract evaporation system through a pipeline. The evaporator and the evaporation technology can guarantee the safety and the stability of the system on the whole and have the advantage of capability of realizing modularization and automatic production.

Owner:JIANGSU 707 NATURAL PHARMA

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap