Micro-pore zeolite, preparation method and application thereof

A technology of microporous zeolite and zeolite, applied in chemical instruments and methods, other chemical processes, inorganic chemistry, etc., to achieve good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0022] [Example 1]

[0023] Sodium aluminate (containing 42.0 wt% Al 2 O 3 ) 6.1 grams and 2.0 grams of sodium hydroxide are dissolved in 270 grams of water, then 34.7 grams of hexamethyleneimine are added while stirring, and then 150 grams of silica sol (containing 40% by weight SiO 2 ), 6.5 grams of dimethyldichlorosilane, the material ratio (molar ratio) of the reactant is:

[0024] SiO 2 / Al 2 O 3 = 40

[0025] NaOH / SiO 2 =0.05

[0026] Dimethyldichlorosilane / SiO 2 =0.05

[0027] Hexamethyleneimine / SiO 2 = 0.35

[0028] H 2 O / SiO 2 = 20

[0029] After the reaction mixture is uniformly stirred, it is put into a stainless steel reactor and crystallized at 150°C for 55 hours under stirring. After being taken out, it is filtered, washed and dried. SiO is obtained by chemical analysis 2 / Al 2 O 3 The molar ratio is 42.3.

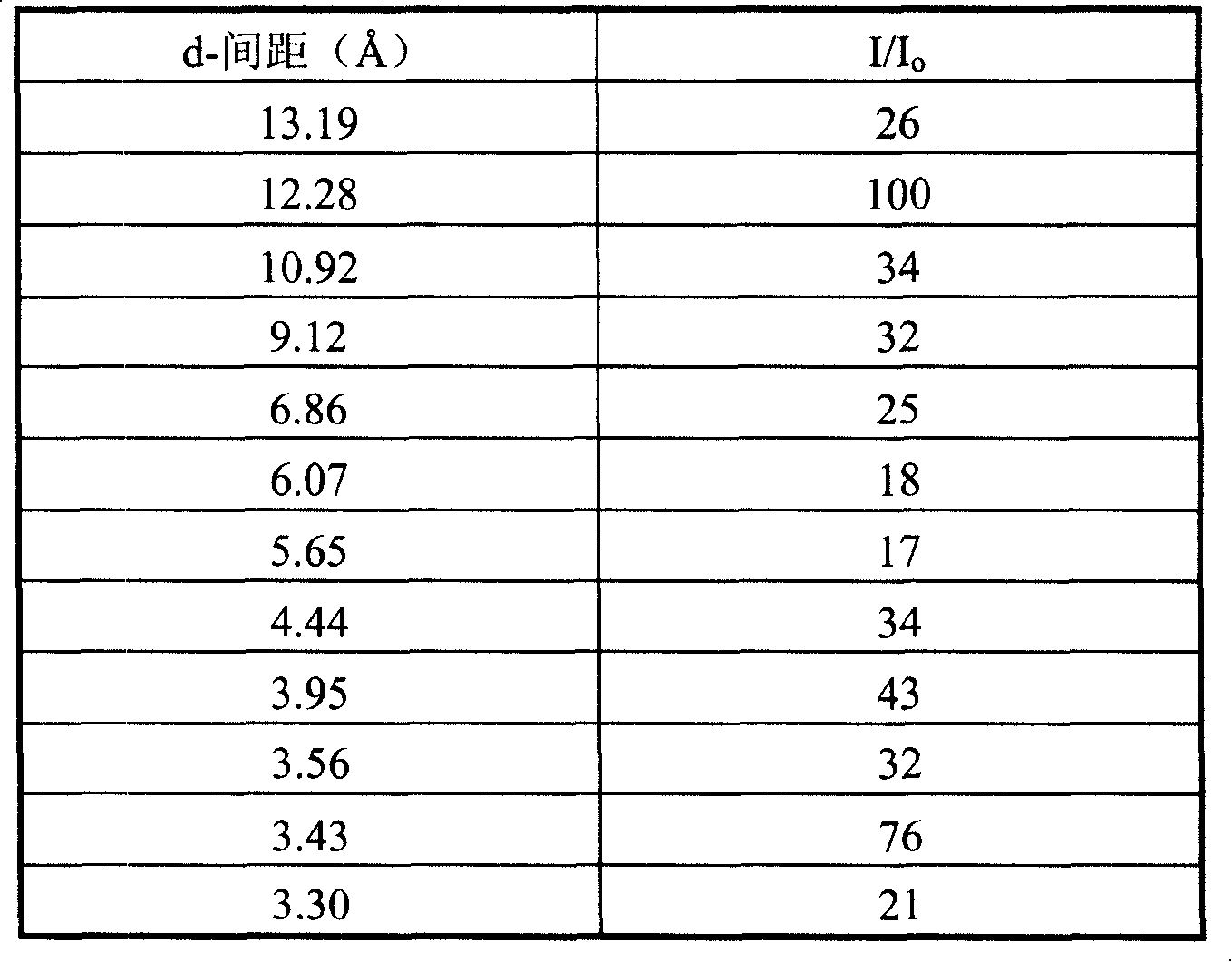

[0030]The dried sample is determined, its Si 29 The NMR solid-state nuclear magnetic spectrum showed a nuclear magnetic resonance peak at -18.4 ppm. The

Example Embodiment

[0033] [Example 2]

[0034] Sodium aluminate (containing 42.0 wt% Al 2 O 3 ) 6.1 grams and 2.0 grams of sodium hydroxide are dissolved in 180 grams of water, then 6.6 grams of trimethylchlorosilane and 43.0 grams of hexahydropyridine are added while stirring, and then 150 grams of silica sol (containing 40% by weight SiO 2 ), the material ratio (molar ratio) of the reactant is:

[0035] SiO 2 / Al 2 O 3 = 40

[0036] NaOH / SiO 2 =0.05

[0037] Trimethylchlorosilane / SiO 2 =0.06

[0038] Hexahydropyridine / SiO 2 = 0.50

[0039] H 2 O / SiO 2 = 15

[0040] After the reaction mixture is uniformly stirred, it is put into a stainless steel reactor and crystallized at 152°C for 50 hours under stirring. After being taken out, it is filtered, washed and dried. SiO is obtained by chemical analysis 2 / Al 2 O 3 The molar ratio is 42.1.

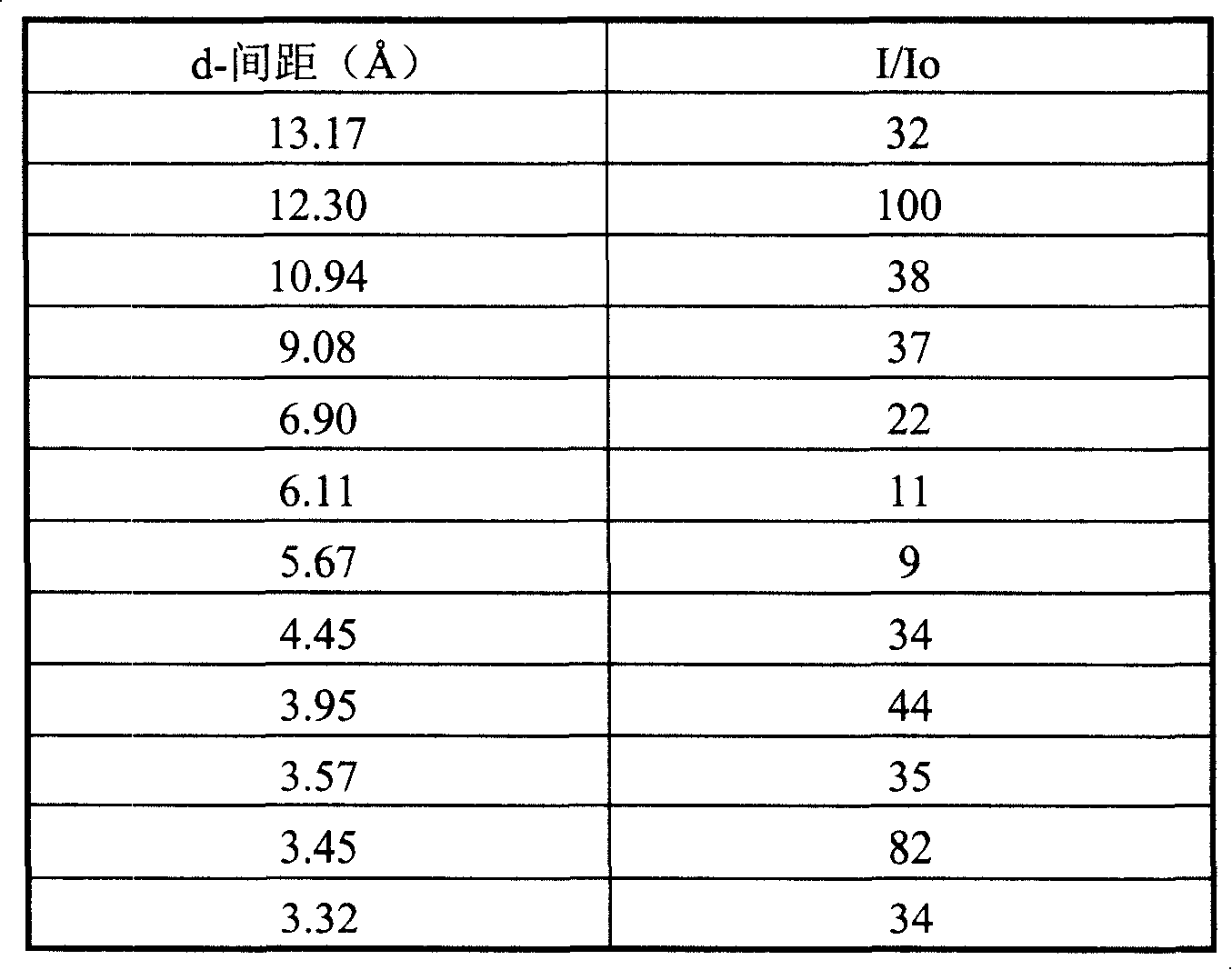

[0041] The dried sample is determined, its Si 29 The NMR solid-state nuclear magnetic spectrum showed a nuclear magnetic resonance peak at 15.2 ppm. The

Example Embodiment

[0044] [Example 3]

[0045] Dissolve 5.1 g of alumina and 2.0 g of sodium hydroxide in 540 g of water, then add 42.5 g of hexamethyleneimine under stirring, then add 60 g of solid silica and 3.2 g of hexamethyldisilazane , The material ratio (molar ratio) of the reactant is:

[0046] SiO 2 / Al 2 O 3 = 20

[0047] NaOH / SiO 2 =0.05

[0048] Hexamethyldisilazane / SiO 2 = 0.04

[0049] Hexamethyleneimine / SiO 2 =0.5

[0050] H 2 O / SiO 2 = 30

[0051] After the reaction mixture is uniformly stirred, it is put into a stainless steel reactor and crystallized at 163°C for 50 hours under stirring. After being taken out, it is filtered, washed and dried. SiO is obtained by chemical analysis 2 / Al 2 O 3 The molar ratio is 17.7.

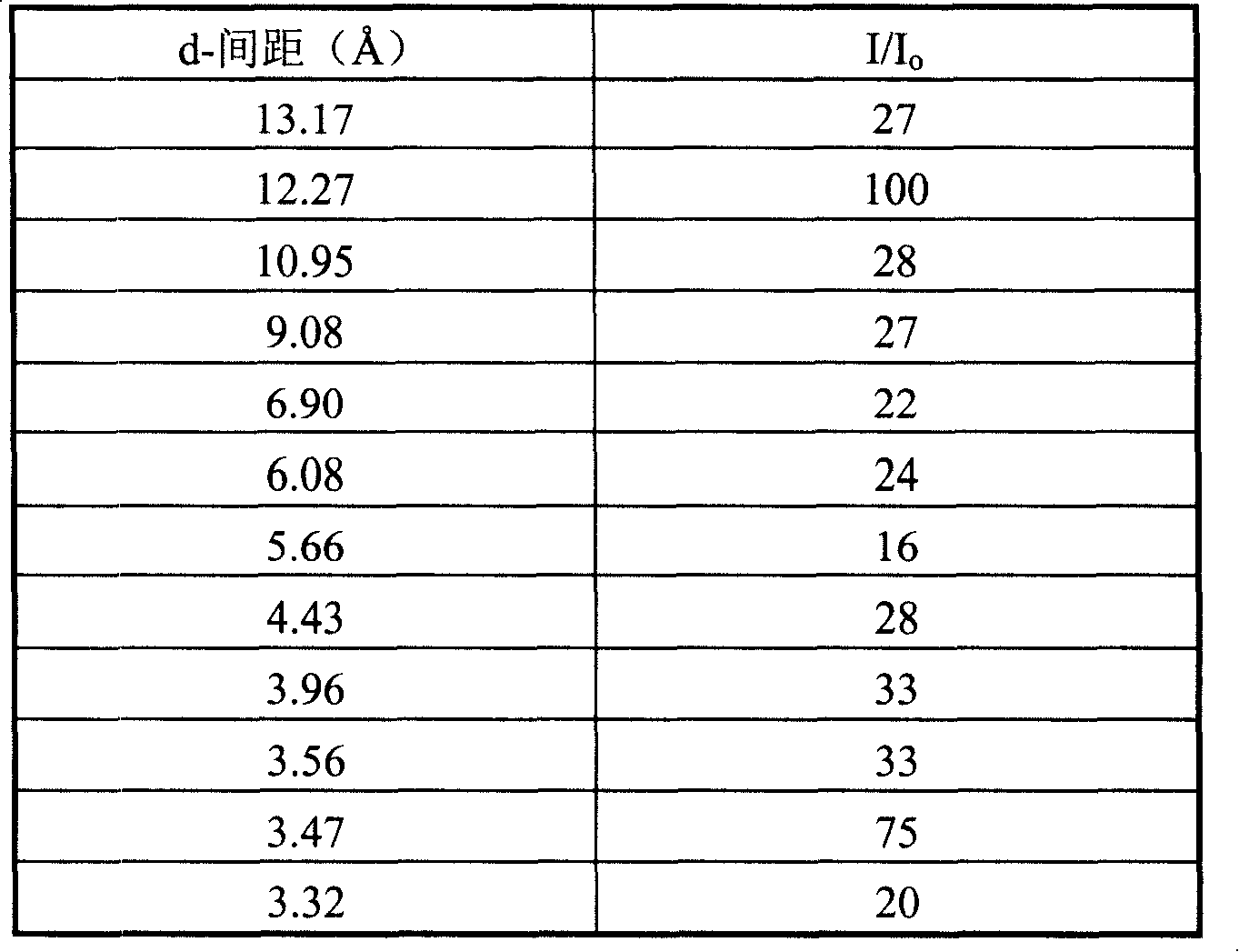

[0052] The dried sample is determined, its Si 29 The NMR solid-state nuclear magnetic spectrum showed a nuclear magnetic resonance peak at 15.8 ppm. The X-ray diffraction data are shown in Table 3.

[0053] table 3

[0054]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap