Micro spherical Fischer-Tropsch synthesis catalyst and preparation method thereof

A Fischer-Tropsch synthesis and catalyst technology, applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, catalysts for physical/chemical processes, etc. , to achieve the effect of promoting dispersion, improving the activity of the catalyst, and improving the technical effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

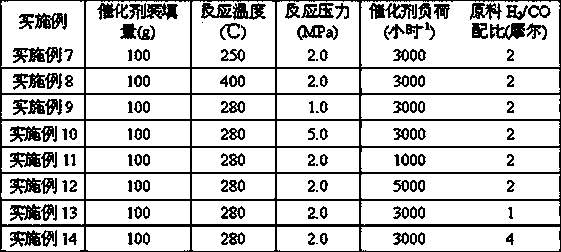

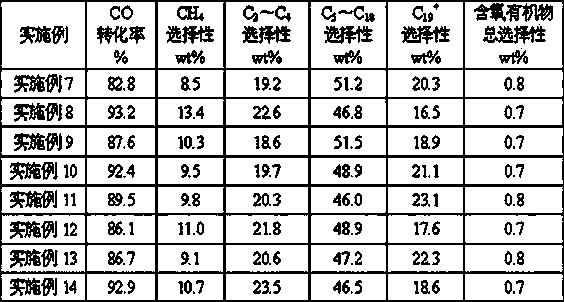

Examples

Example Embodiment

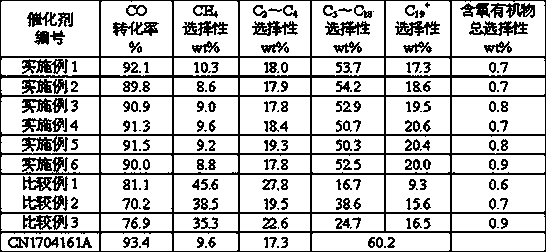

[0036] [Example 1]

[0037] Dissolve 424.2 g of ferric nitrate with 500 g of water to obtain material (I), 3.52 g of potassium hydroxide and 10 g of water for heating to dissolve to obtain material (II), 5.25 g of chromium trioxide plus 10 g of water, stir and dissolve to obtain material (Ⅲ) , Add 184.1 grams of manganese nitrate to material (I) to obtain material (IV).

[0038] Under stirring, add 625 grams of silica sol material with a weight concentration of 40% to material (IV), and then slowly add material (II) and material (III); adjust the acidity of the slurry with ammonia water to make the mixed slurry pH=6.0, after fully stirring, the slurry is obtained. The slurry is formed into microspheres in a spray dryer according to the usual method. Finally, the inner diameter is 89 mm and the length is 1700 mm (φ89×1700 mm). Roasting in a rotary roasting furnace at 500°C for 2.0 hours, the resulting composition is:

[0039] 50% Fe 100 K 5.0 Mn 50.0 Cr 5.0 O x +50%SiO 2 .

[0040] Cata

Example

[0057] 【Examples 2~6】

[0058] The catalysts with different compositions were prepared by basically the same method as in Example 1, and the numbers and compositions of the obtained catalysts were as follows:

[0059] Example 1 50% Fe 100 K 5.0 Mn 50.0 Cr 5.0 O x +50%SiO 2

Example Embodiment

[0060] Example 2 60% Fe 100 Li 3.0 Mn 10.0 Cr 6.5 O x +40%Al 2 O 3

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap