Fuel economizing device

A fuel and shell technology, applied in the combustion method, liquid fuel supply/distribution, etc., can solve the problems of not being fuel-saving, not found, etc., to achieve the effect of fine and uniform oil droplets, increase the number of molecules, and save energy and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

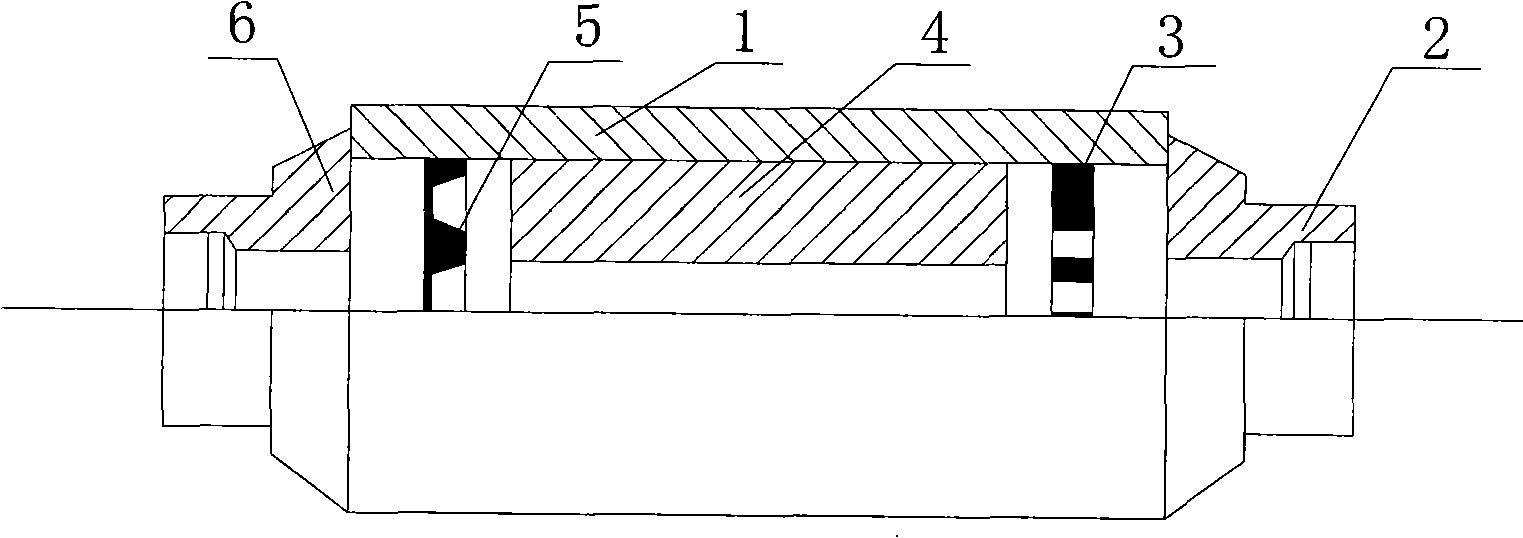

Image

Examples

Example Embodiment

[0020] Example 1: The fuel oil-saving device of the present invention is used in an enterprise's fuel-fired boiler, wherein the precious metal plate includes elements and weight percentages: platinum 0.66%, ruthenium 0.041%, and the balance is copper; the precious metal catalyst plate The elements and weight percentages included are 0.17% rhodium, 0.09% palladium, and the balance is copper. After testing, the fuel saving efficiency reaches 8.8%.

Example Embodiment

[0021] Example 2: The fuel-saving device of the present invention is used in a large diesel engine, wherein the noble metal plate includes elements and weight percentages: 0.6% platinum, 0.09% ruthenium, and the balance is copper; the noble metal catalyst plate The elements and weight percentages included are 0.37% rhodium, 0.11% palladium, and the balance is copper. After testing, the fuel-saving efficiency reaches 7.55%.

Example Embodiment

[0022] Embodiment 3: The fuel and fuel saving device of the present invention is used in a hotel boiler, wherein the precious metal plate includes elements and weight percentages: platinum 0.6%, ruthenium 0.09%, and the balance is copper; the precious metal catalyst plate includes The elements and weight percentages are 0.5% rhodium, 0.19% palladium, and the balance is copper. After testing, the fuel-saving efficiency reached 14.86%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap