Feeding mechanism for numerical control double surface lapping machine

A double-sided grinding and feeding mechanism technology, applied in the grinding field, can solve problems such as inconvenient operation, out-of-tolerance workpiece size, and inaccurate measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

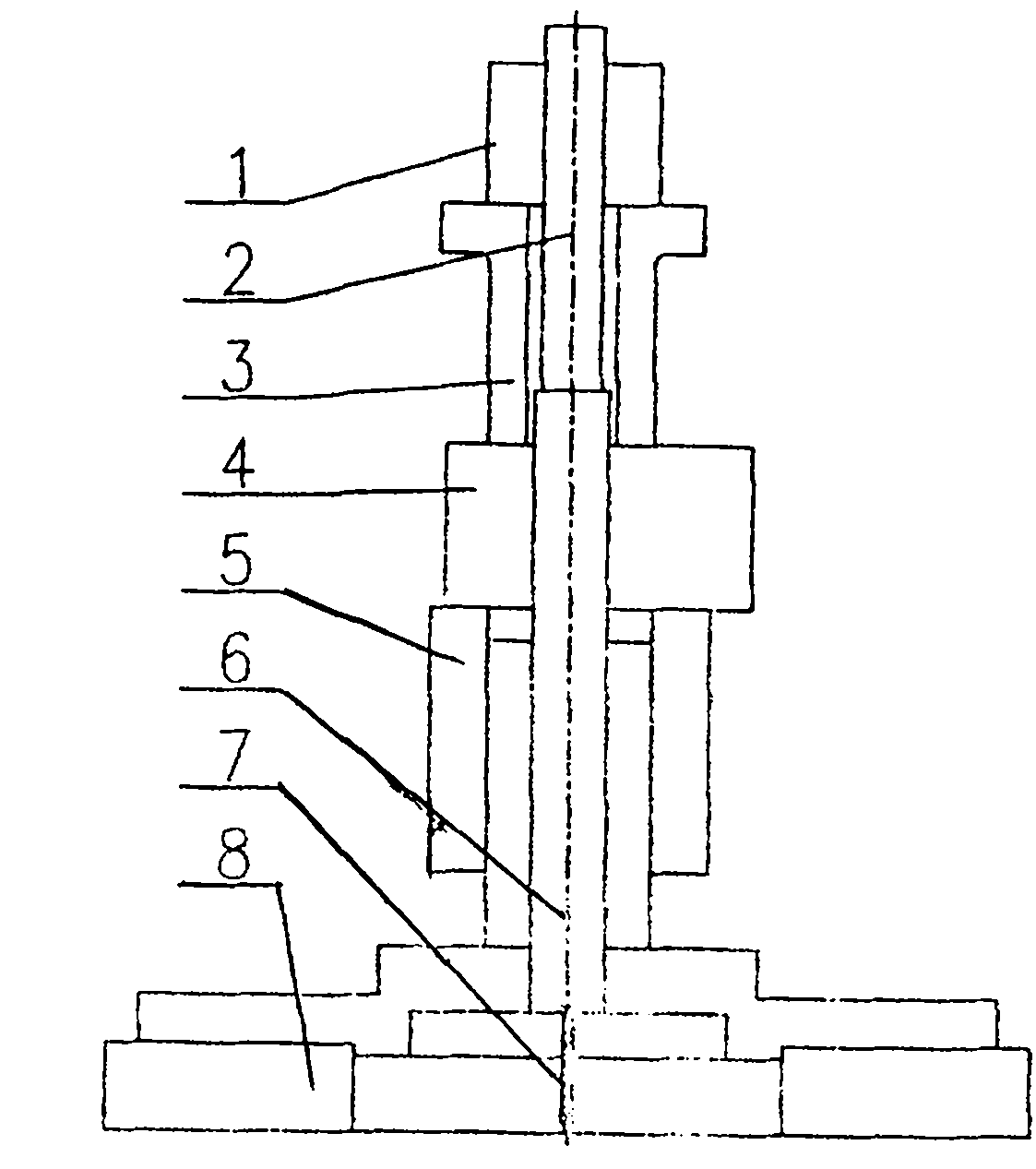

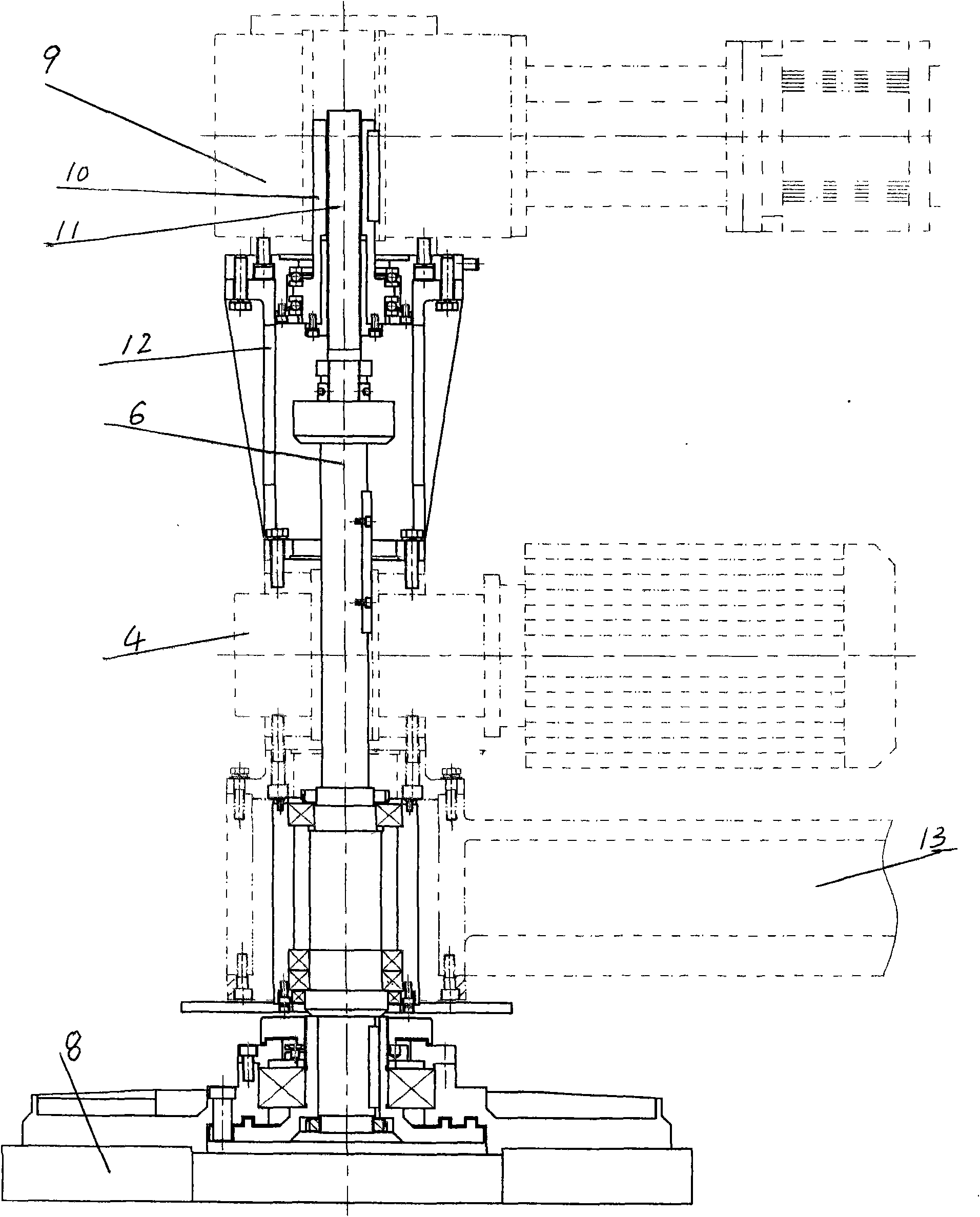

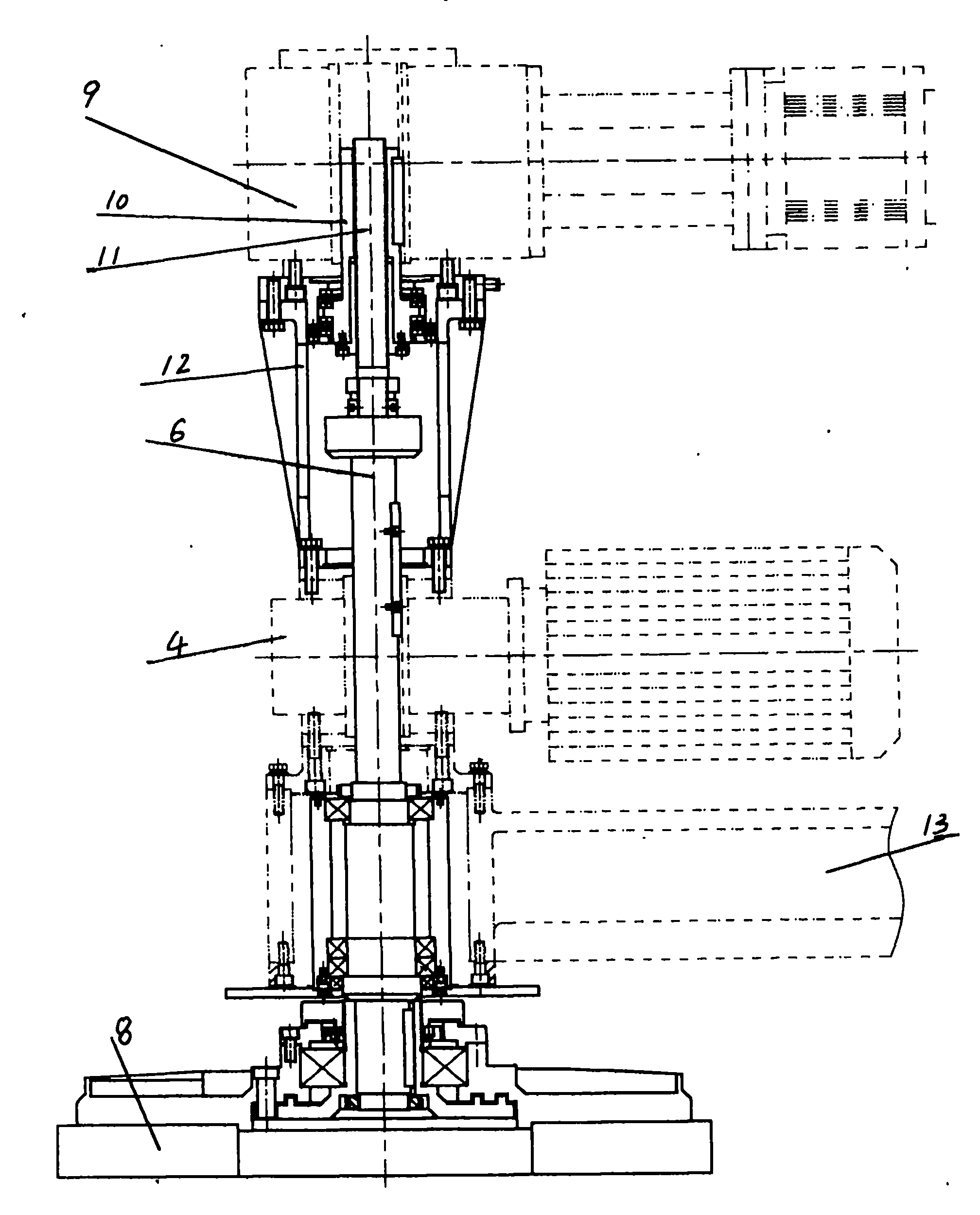

[0006] The embodiment is described in detail in conjunction with the above accompanying drawings. In the prior art, the cylinder 1 is combined on the cylinder support 3, the cylinder piston rod 2 is connected with the upper grinding disc 8 through the shaft 6, and the reduction motor 4 is installed under the cylinder support 3. Guide sleeve 5 and measuring head 7, (see figure 1 ), when working, the piston rod 2 in the cylinder drives the upper grinding disc to move through the shaft 6. In the present invention, the servo motor 9 is combined on the motor support 12, the motor support is fixed on the reduction motor 4 with screws, the reduction motor is fixed on the rocker arm 13 with screws, and the other end of the rocker arm 13 is sleeved on the bed On the column, you can shake the rocker arm back and forth by hand to center the upper and lower grinding discs. The ball screw cover 10 is equipped with a ball screw 1, which is driven by the servo motor to rotate, so that the ball

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap