Auto-cascade heat pump with middle throttling element and adjusting method thereof

A throttling element, self-cascading technology, applied in refrigeration components, fluid circulation arrangements, lighting and heating equipment, etc., can solve the problems of poor overall performance, large working temperature difference, unstable performance, etc. Large temperature difference and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

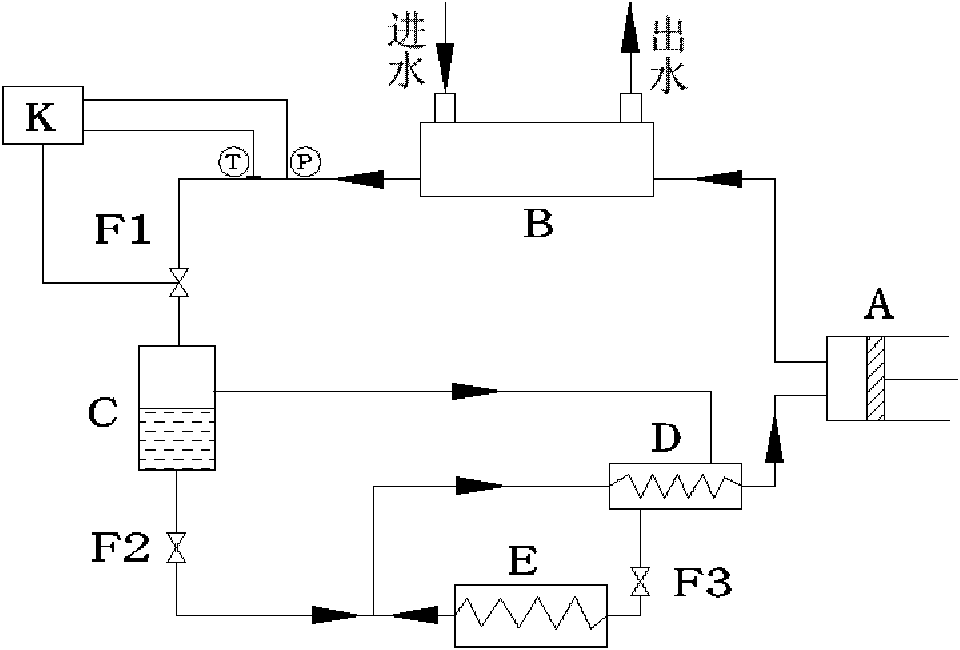

[0017] Example: see figure 1 , using the non-azeotropic refrigerant R134a / R123 as the system circulating working medium, the working medium is compressed into a high-temperature and high-pressure gas after being compressed by the refrigeration compressor A, and is partially condensed in the condenser B to form a gas-liquid two-phase with a small dryness Refrigerant or liquid-phase refrigerant with a small subcooling degree, and then throttling through the middle throttling element F1 to obtain a relatively high-quality refrigerant and enter the gas-liquid separator C for gas-liquid separation, which is rich in R134a The refrigerant flow is condensed in the condensing evaporator D and then throttled by the low-temperature stage throttle valve F3 to obtain a lower evaporation temperature. The low-boiling point component refrigerant flow is mixed and enters the low-temperature side of the condenser evaporator D to evaporate and absorb heat, and then directly enters the suction por

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap