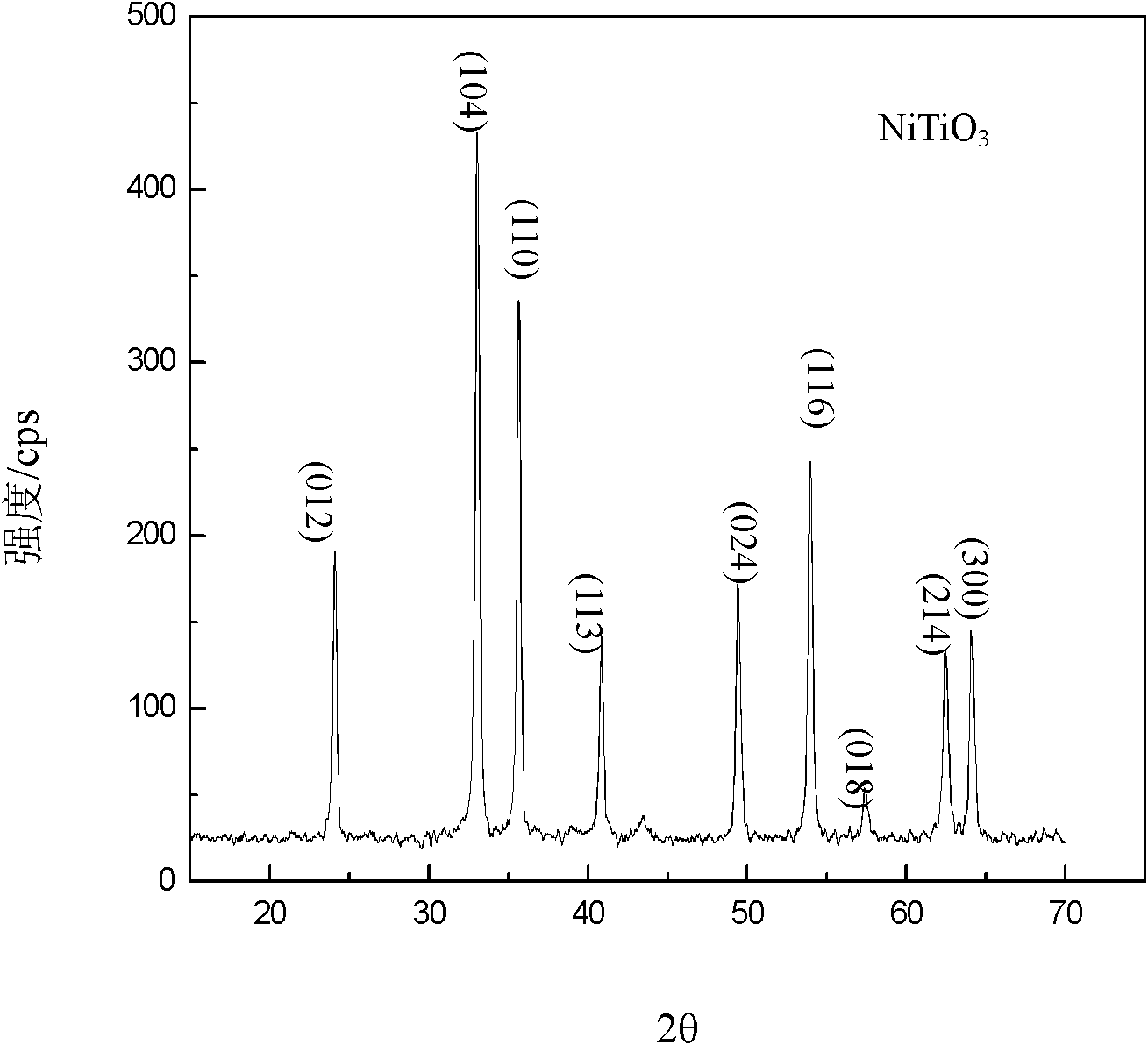

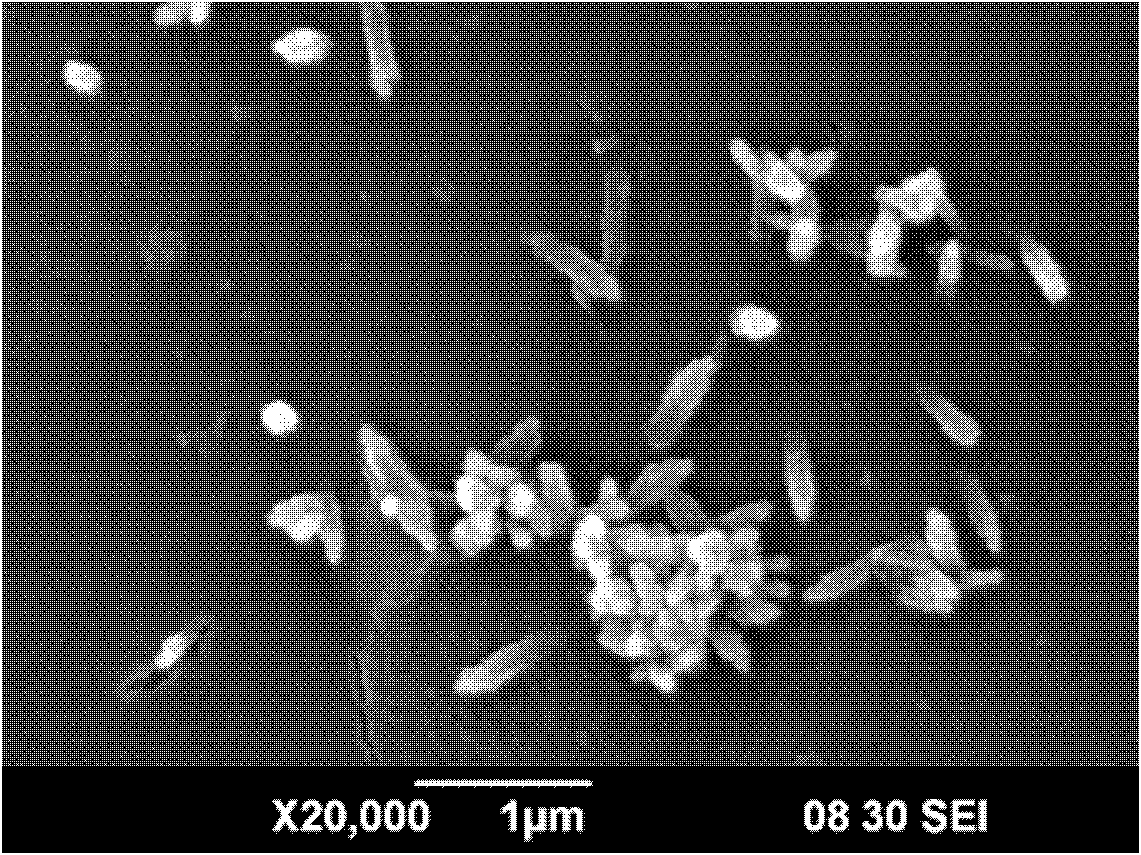

Preparation method of bar-shaped NiTiO3 nano-crystalline

A nanocrystalline and rod-shaped technology is applied in the field of UV-microwave combined preparation, which can solve the problem of impurities in powder, and achieve the effects of short reaction period, convenient operation and small grain size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: Add analytically pure nickel nitrate hexahydrate in dehydrated alcohol, and constantly stir, be mixed with Ni 2+ The transparent solution with a concentration of 0.5mol / L is denoted as A; analytically pure tetrabutyl titanate is added to the A solution, so that Ni 2+ with Ti 4+ The molar ratio of oxalic acid to all cations is 0.5:1, and the mixed solution is obtained by stirring continuously, and then oxalic acid is added to the mixed solution, so that the molar ratio of oxalic acid to all cations is 0.5:1, and finally water with 4 times the volume of absolute ethanol is added, and stirred After uniformity, the solution formed after standing still is recorded as B; after the above solution B is irradiated in a UV-microwave instrument for 25 hours, the solution has precipitation, filter the precipitation and wash it with acetone, put it in a drying oven, and dry it at 80°C for 12 hours. That is to get the final product - rod-shaped NiTiO without impurities

Embodiment 2

[0015] Embodiment 2: Add analytically pure nickel nitrate hexahydrate in dehydrated alcohol, and constantly stir, be mixed with Ni 2+ The transparent solution with a concentration of 0.6mol / L is denoted as A; analytically pure tetrabutyl titanate is added to the A solution, so that Ni 2+ with Ti 4+ The molar ratio of oxalic acid and all cations is 1:1, and the mixed solution is obtained by stirring continuously, then add oxalic acid to the mixed solution, so that the molar ratio of oxalic acid and all cations is 1:1, and finally add water 4 times the volume of absolute ethanol, stir After uniformity, the solution formed by standing still is recorded as B; after the above solution B is irradiated in a UV-microwave instrument for 12 hours, the solution has precipitates, filter the precipitates and wash them with acetone, put them in a drying oven, and dry them at 100°C for 10 hours. That is to get the final product - rod-shaped NiTiO without impurities 3 Nanocrystalline.

Embodiment 3

[0016] Embodiment 3: Add analytically pure nickel nitrate hexahydrate in dehydrated alcohol, and constantly stir, be mixed with Ni 2+ The transparent solution with a concentration of 0.8mol / L is denoted as A; analytically pure tetrabutyl titanate is added to the A solution, so that Ni 2+ with Ti 4+ The molar ratio of oxalic acid and all cations is 1:1, and the mixed solution is obtained by stirring constantly, then add oxalic acid to the mixed solution, so that the molar ratio of oxalic acid and all cations is 1.5:1, and finally add water 6 times the volume of absolute ethanol, stir After uniformity, the solution formed after standing still is recorded as B; after the above solution B is irradiated in a UV-microwave instrument for 36 hours, the solution has precipitates, filter the precipitates and wash them with acetone, put them in a drying oven, and dry them at 90°C for 11 hours. That is to get the final product - rod-shaped NiTiO without impurities 3 Nanocrystalline.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap