Dehydrogenase electrode, and preparation method and application thereof

A dehydrogenase and electrode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor reversibility of electrochemical reactions, complicated preparation process, poor electronic conductivity, etc., and achieve high electrochemical reversibility and wide source of raw materials , The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] Example 1. Preparation of polyaniline

[0024] Dissolve 186mg aniline monomer and 456mg potassium peroxodisulfate in 10mL 0.5M hydrochloric acid solution, react for 5 hours in an ice bath at 0~5℃, filter the precipitate, wash with hydrochloric acid and double distilled water respectively, and vacuum dry to obtain green poly Aniline (number average molecular weight 75400).

Example Embodiment

[0025] Example 2. Preparation of polyaniline

[0026] Add 294mg of aniline monomer and 348mg of manganese dioxide to 20mL of 1M hydrochloric acid solution, react in an ice bath at 0~10℃ for 10 hours, filter the precipitate, wash with hydrochloric acid and double distilled water, and vacuum dry to obtain green polyaniline ( The number average molecular weight is 32100).

Example Embodiment

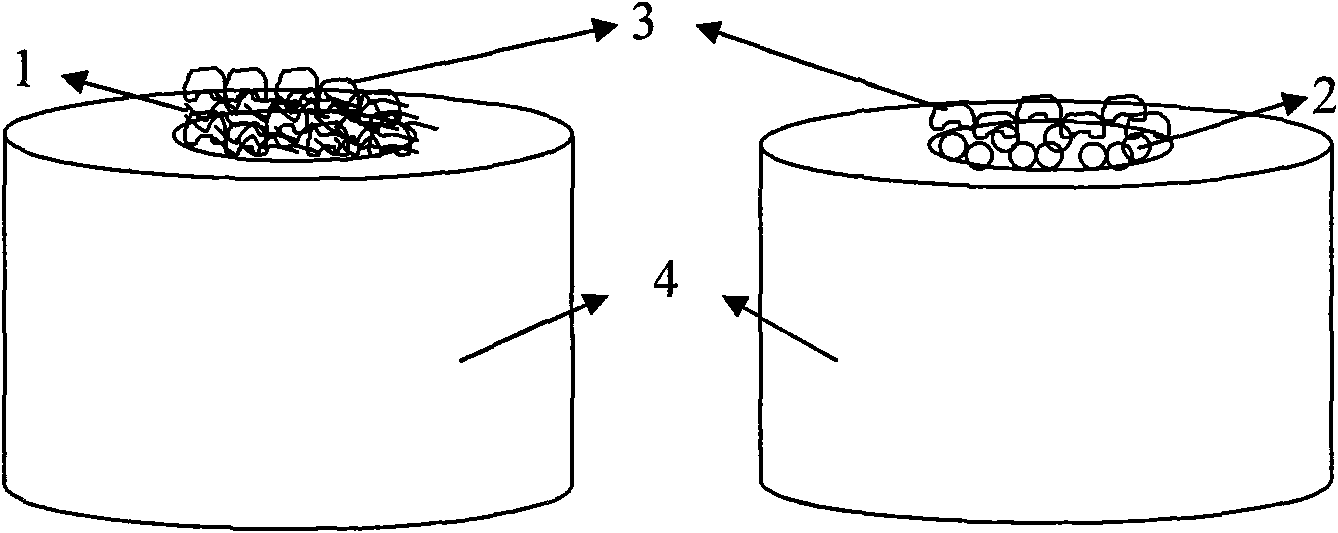

[0027] Example 3. Polyaniline / carbon nanotube composite electrode

[0028] 1.5 mg of polyaniline (number average molecular weight 75400) prepared in Example 1 and 3 mg of carbon nanotubes (Shenzhen Nanoport Co., Ltd., diameter 2 , The ultrasonic frequency is 40kHz) for 1 hour, form a composite suspension of the two, take 6μL and apply it on a 0.07 cm2 glassy carbon substrate electrode, and dry at room temperature for 30 minutes to obtain a polyaniline / carbon nanotube composite electrode .

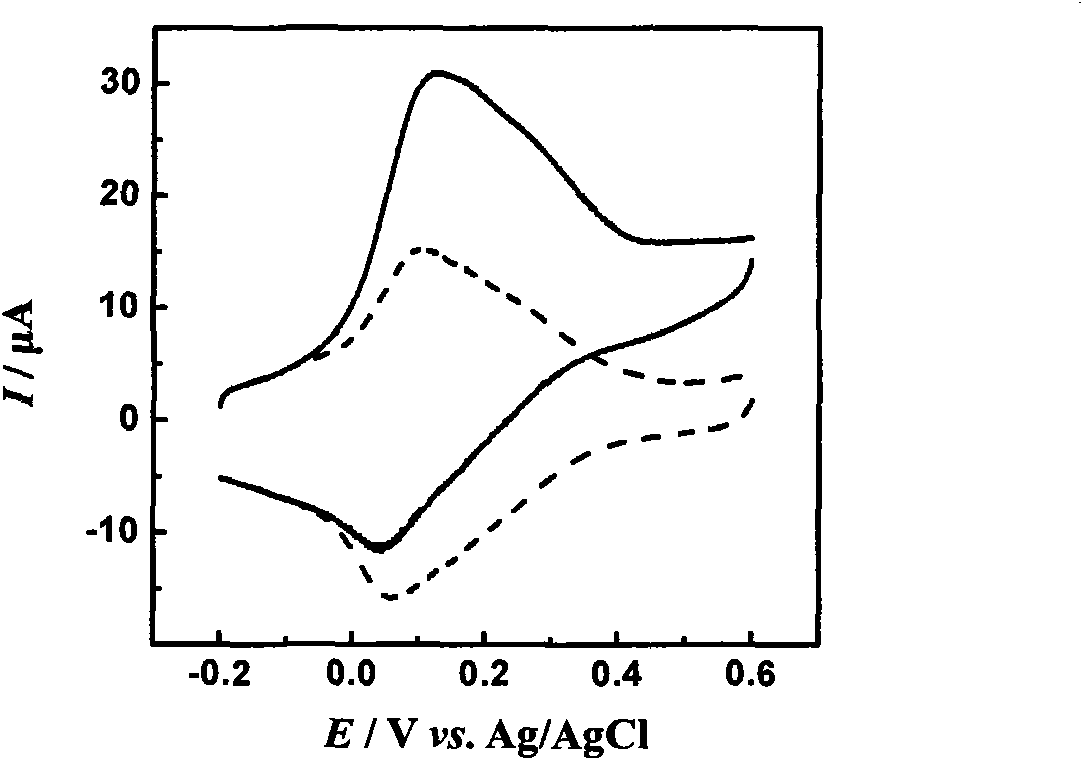

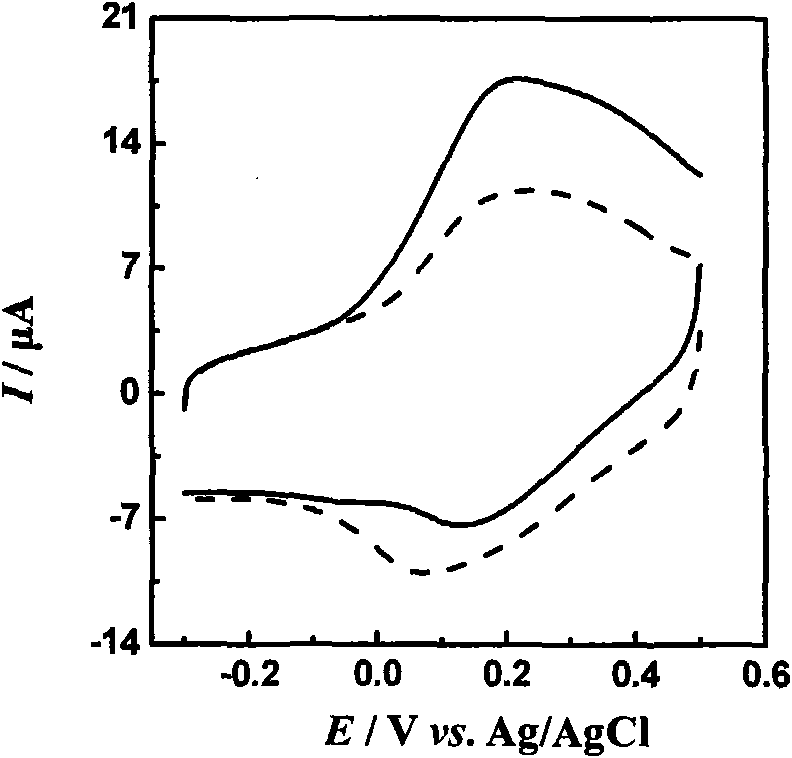

[0029] At the same time, the catalytic effect of the electrode on nicotinamide adenine dinucleotide (NADH, reduced type) was tested. The solution used in the test was a phosphate buffer solution pH=7. The results are shown in figure 2 . figure 2 The dotted line and the solid line are the cyclic voltammetry curves of the polyaniline / carbon nanotube composite electrode without and containing 4mM nicotinamide adenine dinucleotide (NADH, reduced type), and the potential scanning speed is 20mVs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap