High-modulus asphalt macadam (HMAM) base course structure and laying method thereof

A technology of pavement base and asphalt macadam, which is applied in the direction of roads, roads, road repairs, etc., can solve the problems of single semi-rigid base structure, easy to generate reflection cracks, poor fatigue durability, etc., and achieve improved fatigue and deformation resistance. Effects of saving resources and improving fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] Example 1

[0027] A high modulus asphalt macadam (HMAM) pavement base layer structure, using 1 ton of No. 10 asphalt as the binder, 22.2 tons of continuous densely graded crushed stone as the aggregate (see Table 1), and heating the aggregate to 175°C It is heated to 160 to form a mixture, and the mixture is discharged at 170°C; when laying, the surface of the underlying layer is first cleaned; then the mixed mixture is spread on the underlying layer and rolled into a shape; During the paving and rolling process; the paving temperature is 165°C, the initial pressing temperature is 155°C, the final pressing temperature is 100°C, and the forming thickness is 6-10cm; after waiting for the end of the age, the traffic is opened, and the porosity is 6%.

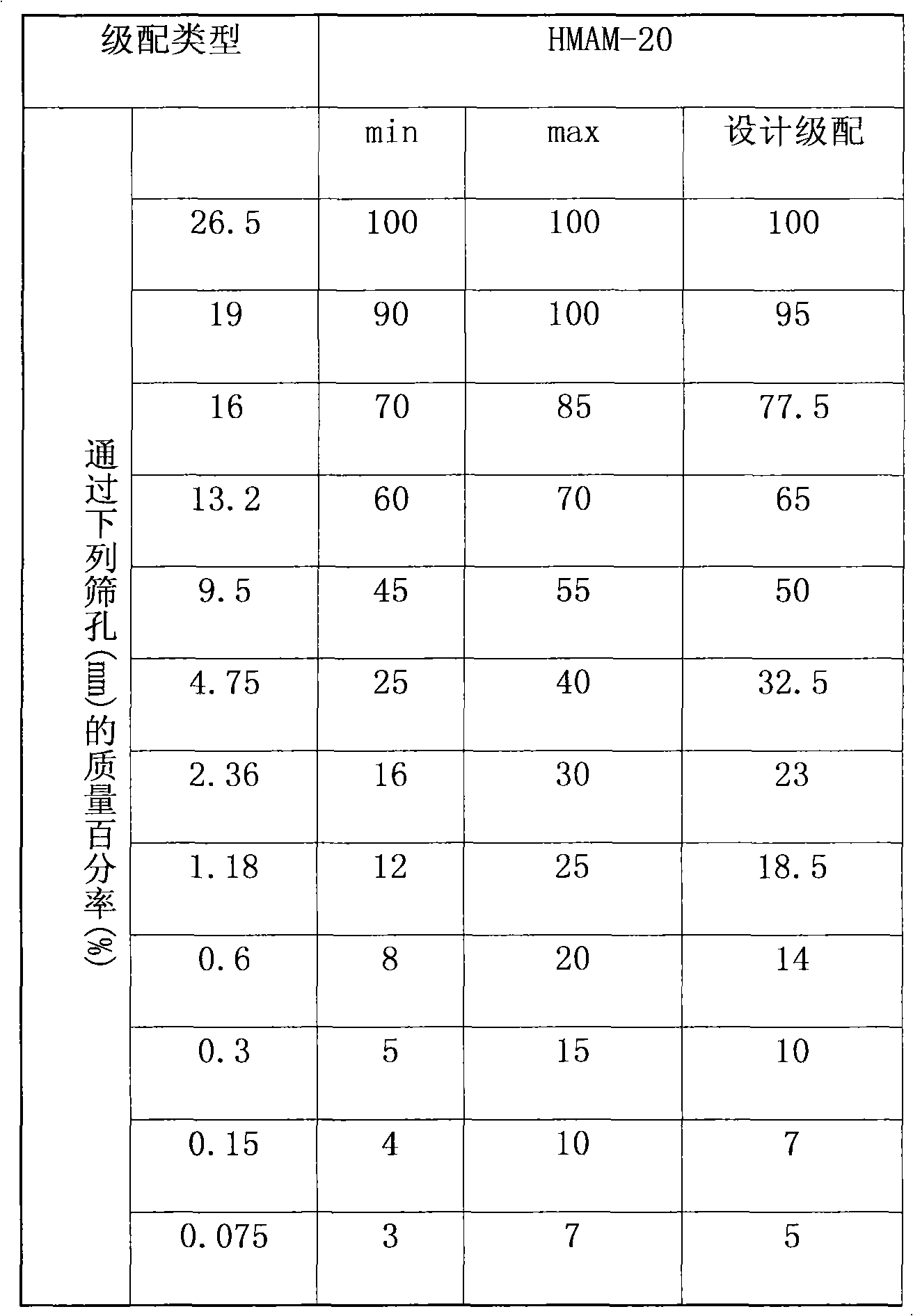

[0028] Table 1 Grading table of HMAM-20 (the maximum nominal particle size of aggregate is 19mm)

[0029]

Example Embodiment

[0030] Example 2

[0031] A high modulus asphalt macadam (HMAM) pavement base layer structure, using 1 ton of No. 30 asphalt as the binder, 16.7 tons of continuous densely graded crushed stone as the aggregate (see Table 2), and heating the aggregate to 180℃ It is mixed with the binder heated to 170°C to form a mixture, and the mixture is discharged at 175°C; when laying, the surface of the lower layer is first cleaned; then the mixed mixture is spread on the lower layer and rolled to form, During the paving and rolling process, the paving temperature is ≥170℃; the initial pressing temperature is ≥160℃, the final pressing temperature is ≥110℃, and the forming thickness is 8-12cm. After waiting for the end of the age, the traffic will be opened, and the porosity is 10%.

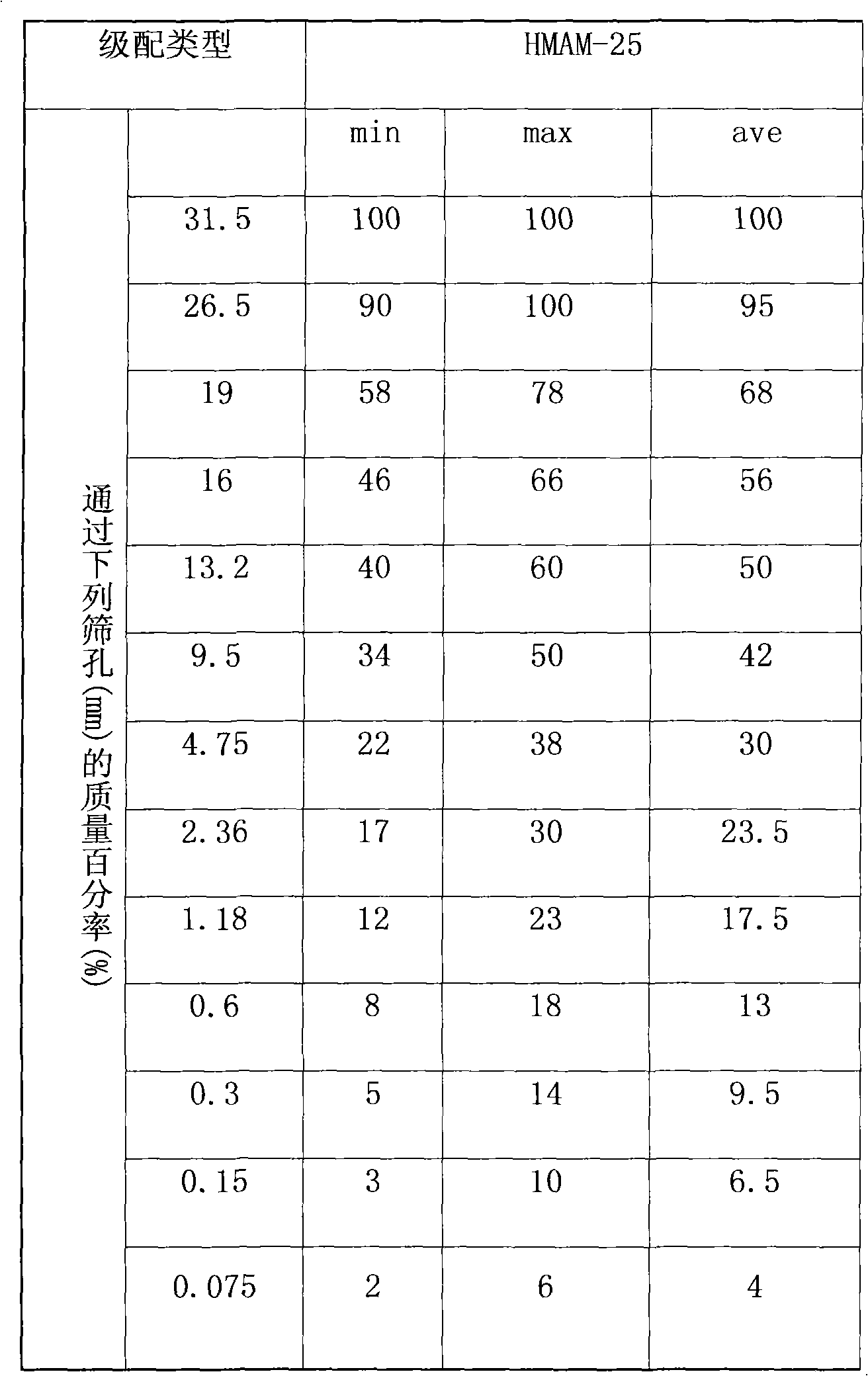

[0032] Table 2 Grading table of HMAM-25 (the maximum nominal particle size of aggregate is 26.5mm)

[0033]

Example Embodiment

[0034] Example 3

[0035] A kind of high modulus asphalt macadam (HMAM) pavement base layer structure, using 1 ton of No. 20 asphalt as the binder, and 20.7 tons of continuous densely graded crushed stone as the aggregate (see Table 3, the maximum nominal particle size of the aggregate is 31.5 mm), the aggregate is heated to 185℃ and the binder heated to 175℃ to form a mixture, and the 180℃ mixture is discharged; when laying, first clean the surface of the underlying layer; then spread the mixed mixture Spread on the underlying layer and roll into forming; during the paving and rolling process, the paving temperature is greater than or equal to 175°C, the initial pressing temperature is greater than or equal to 165°C, the final pressing temperature is greater than or equal to 120°C, and the forming thickness is greater than or equal to 9-15cm; waiting for the end of the age Open to traffic, the void ratio is 8%.

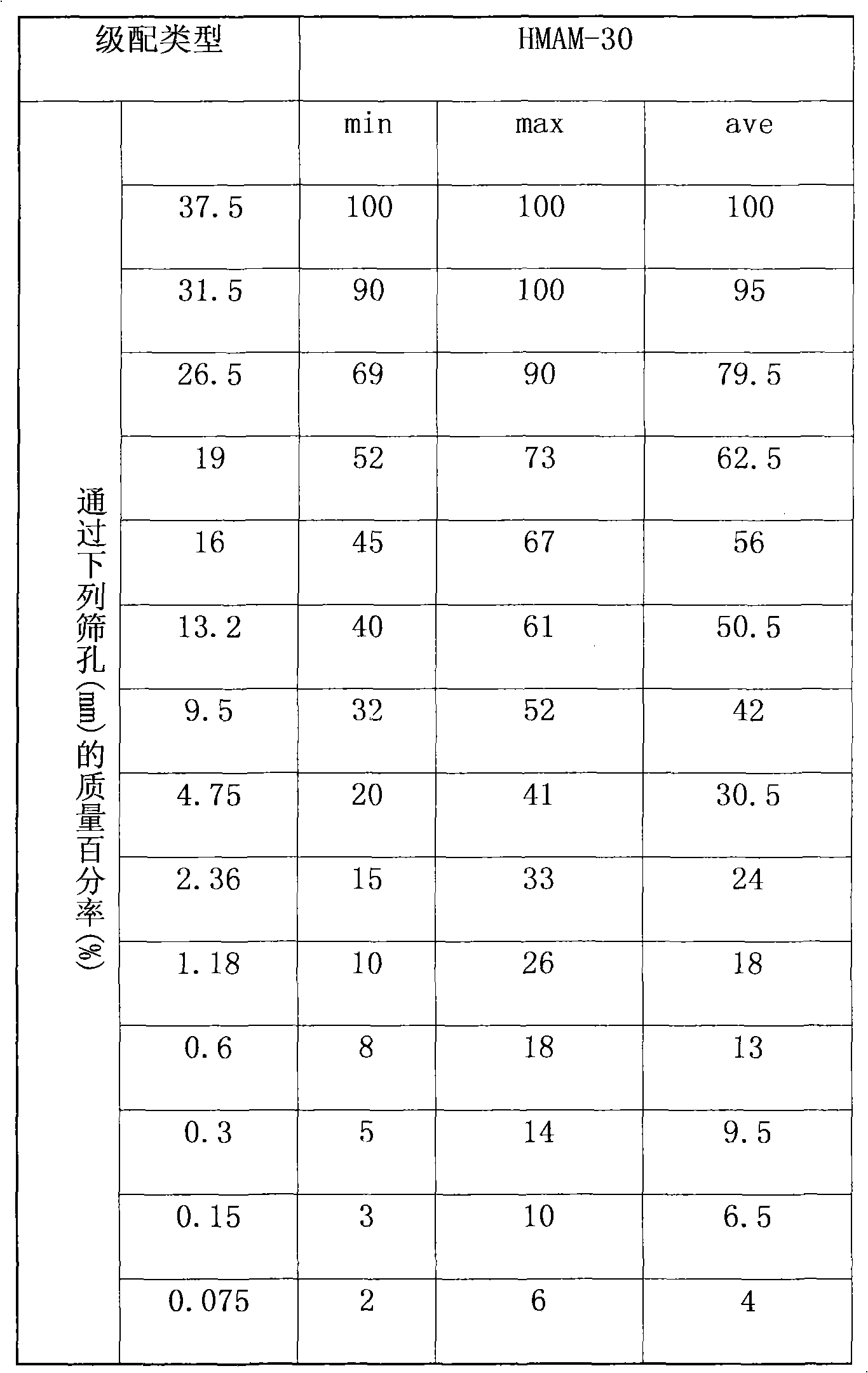

[0036] Table 3 Grading table of HMAM-30 (the maximum nominal particle

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum nominal particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap