Slurry density sensor

A density sensor and sensor technology, applied in the field of sensors, can solve problems such as poor fluidity, achieve the effects of improving sensitivity and accuracy, increasing flow speed, and reducing diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

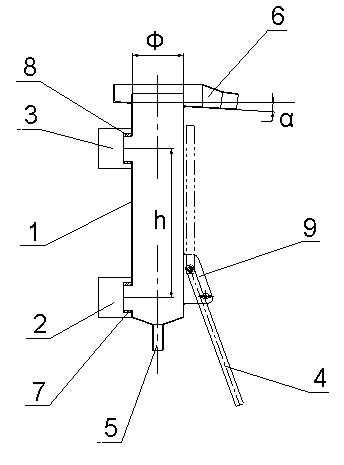

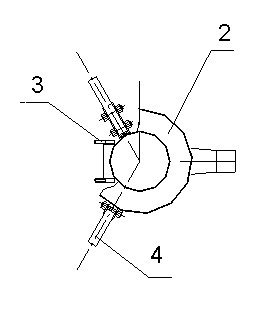

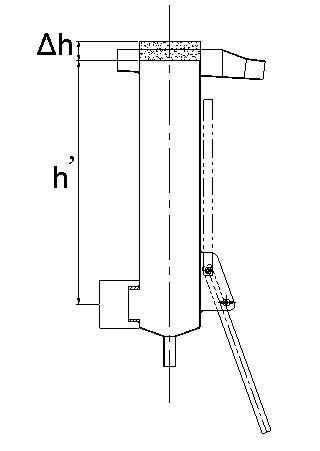

[0024] Such as figure 1 , figure 2 , a kind of slurry density sensor, it comprises standard measuring barrel, sensor A2, sensor B3 and tripod 4, and the lower end of standard measuring barrel 1 is provided with cement slurry inlet 5, and upper end is provided with slurry outlet 6, and side wall is provided with distance The threaded mounting port A7 and the threaded mounting port B8 are h, the threaded mounting port B8 is located above the threaded mounting port A7 and the threaded mounting port A7 and the threaded mounting port B8 are on the same axis, and the sensor A2 and the sensor B3 are respectively installed on the threaded mounting port A7 and the threaded mounting port B8 and fixed with screws, the side wall of the standard measuring barrel 1 is provided with a tripod fixing frame 9, the tripod 4 i

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap