Range hood oil cup structure

A technology for absorbing oil fume and oil, which is applied in the field of the structure of oil fumes and oil cups, can solve problems such as oil dripping on the oil net, and achieve the effect of keeping clean.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

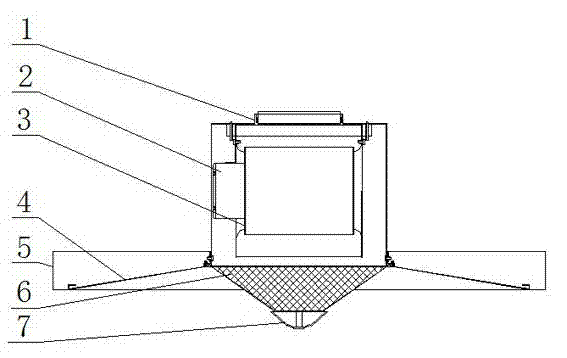

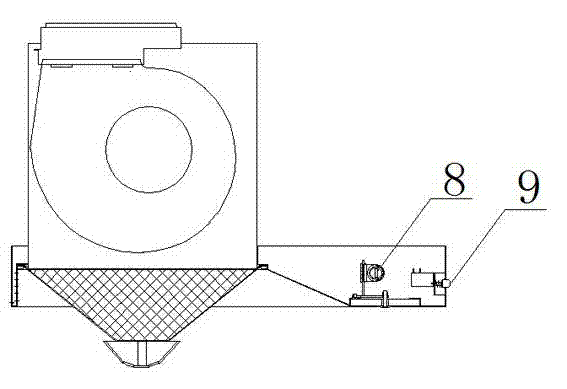

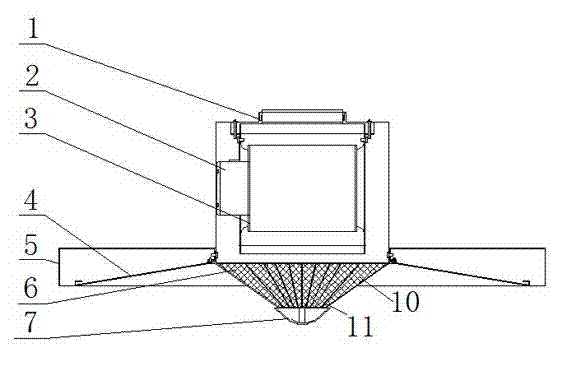

[0012] See image 3 , Figure 4 , Figure 5 , the present invention includes an air outlet seat 1, a motor 2, an upper casing 5, and a lower casing 4. The lower end of the air outlet seat 1 is equipped with a motor 2, corresponding to the bottom of the volute 3 of the motor 2, and the joint part of the upper casing 5 and the lower casing 4 is installed There is an oil filter screen 6, the fluorescent tube 8 is arranged in the upper shell 5, the side wall of the upper shell 5 is provided with a control button 9, and an oil cup 7 is arranged at the bottom of the oil filter screen 6. The oil screen 6 is bent inward into a plurality of arcs, and a hollow oil groove 11 is arranged between the adjacent arc surfaces 10. The oil groove 11 is bent to the outside of the oil filter screen 6, so that oil droplets are accumulated in the volute 3. After flowing onto the oil filter screen 6, due to the surface tension of the liquid and its improved structure, on the surface of the arc oil fil

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap