Particulate combustion catalyst

A technology of burning catalysts and catalysts, which is applied in the directions of catalyst activation/preparation, physical/chemical process catalysts, and separation of dispersed particles, which can solve the problems of cost increase and achieve excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5、 comparative example 1~4

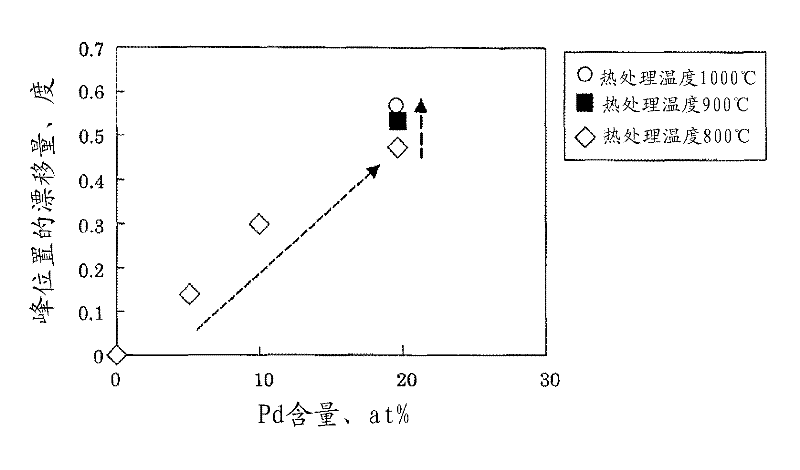

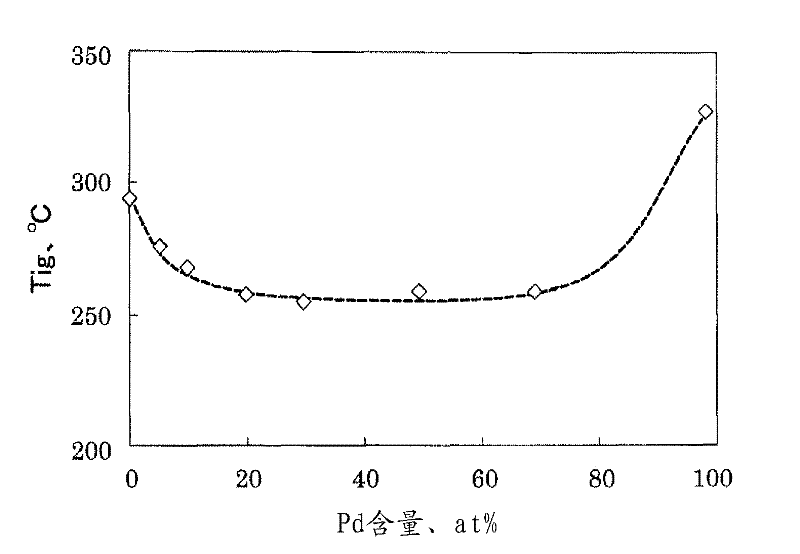

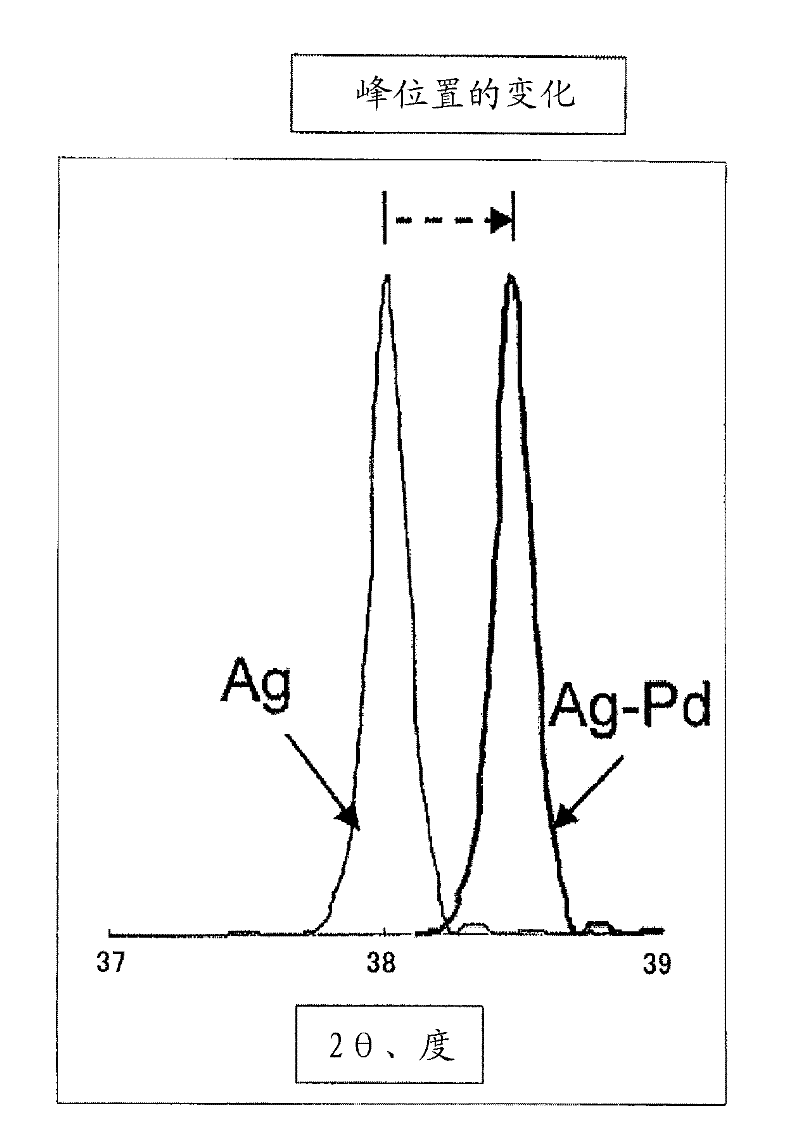

[0040] A silver nitrate aqueous solution (Comparative Example 1), a silver nitrate aqueous solution and a palladium nitrate aqueous solution having an Ag atom:Pd atom=95:5 mixed solution (Comparative Example 2) at 5 mass % in terms of metal elements relative to the mass of the support ), Ag atom of aqueous silver nitrate solution and palladium nitrate aqueous solution: the mixed solution of Pd atom=90:10 (comparative example 3), the Ag atom of silver nitrate aqueous solution and palladium nitrate aqueous solution: the mixed solution of Pd atom=80:20 (implementation Example 1), silver nitrate aqueous solution and palladium nitrate aqueous solution Ag atom: Pd atom=70: 30 mixed solution (embodiment 2), silver nitrate aqueous solution and palladium nitrate aqueous solution Ag atom: Pd atom = 50: 50 mixed solution (Example 3), Ag atom of silver nitrate aqueous solution and palladium nitrate aqueous solution: the mixed solution of Pd atom=30:70 (embodiment 4), palladium nitrate aqueous

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap