Selective complexing agent loaded graphitized carbon black and its application in palladium extraction

A graphitized carbon black, graphitized carbon black technology, applied in other chemical processes, improvement of process efficiency, chemical instruments and methods, etc., can solve problems such as low extraction recovery, low enrichment multiple, slow phase separation, etc. Achieve high extraction recovery rate, overcome easy emulsification, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

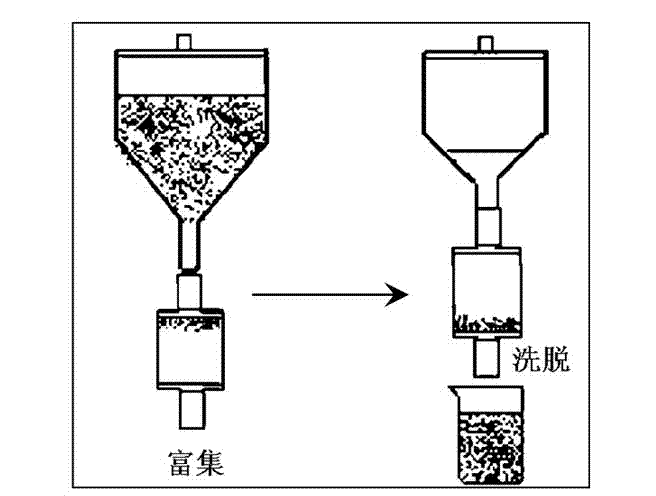

[0028] Example 1: The solid phase extraction cartridge used is: 10 mm×10 mm, packed with filler (graphitized carbon black with selective complexing agent) 1.2 g; the extraction liquid is the hydrochloric acid, sodium chlorate leaching solution of waste circuit boards, and palladium The concentration was 5.21 mg / L, and the pH was adjusted to 2.1; the solution was passed through the column at a flow rate of 20 mL / min, and the column volume was 0.8 L. After the enrichment, the column was eluted with 5.0 mL of 1% thiourea in the opposite direction. Enriched palladium. Under this condition, the enrichment factor can reach 160 times, and the recovery rate of palladium can reach 97.2%. Palladium in the eluate is smelted and recovered by conventional methods.

Example Embodiment

[0029] Example 2: The solid phase extraction cartridge used is: 10 mm×10 mm, packed with filler (graphitized carbon black with complexing agent) 1.2 g; the solution to be extracted is the cyanide tailings leaching solution, the palladium concentration is 1.2 mg / L, and the pH is adjusted The column volume is 4.5 L. After the enrichment is completed, 5 mL of 1.5% thiourea is used to elute the enriched palladium on the cartridge in the opposite direction. Under these conditions, the enrichment factor can reach 900 times, and the recovery rate of palladium can reach 96.3%. Palladium in the eluate is smelted and recovered by conventional methods.

Example Embodiment

[0030] Example 3: The solid phase extraction cartridge used is: 10 mm×10 mm, packed with 1.2 g packing (graphitized carbon black with complexing agent); the extraction solution is palladium ore leachate, containing 15.4 mg / L of palladium, and the pH is adjusted to 2.3; The solution was passed through the column at a flow rate of 15 mL / min, and the column volume was 1.1 L. After the enrichment, 5 mL of 0.8% thiourea was used to elute the enriched palladium on the small column. Under this condition, the enrichment factor can reach 220 times, and the recovery rate of palladium can reach 95.8%. Palladium in the eluate is smelted and recovered by conventional methods.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap