Pilot valve air tightness testing device

A test device and tightness technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum, pipes/pipe joints/fittings, mechanical equipment, etc., which can solve the problems of low detection automation, high labor cost, and slow test speed, etc. problems, to achieve a high degree of detection automation, save labor costs, and ensure the effect of test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

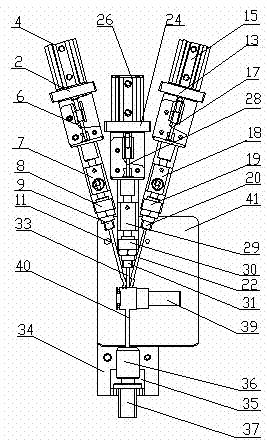

[0021] like figure 1 Shown, the present invention comprises E pipe high-pressure air intake mechanism, S pipe sealing mechanism, C pipe high-pressure air intake mechanism, D pipe sealing mechanism and stainless steel reflector; The air intake mechanism and the D pipe closing mechanism are respectively connected to the E pipe, S pipe, C pipe and D pipe of the pilot valve. The stainless steel tube reflector 41 is installed directly below the pilot valve 39. The reflector 41 is immersed in water through the mechanical structure, and the purpose of setting the stainless tube reflector 41 is to facilitate the operator to observe the air leakage of the lower part of the pilot valve, which improves the reliability of the test results.

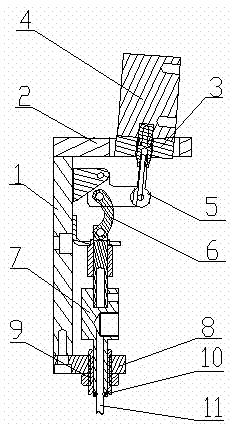

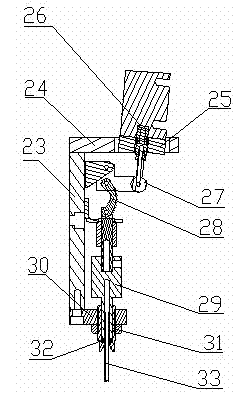

[0022] like figure 1 , figure 2 As shown, the E-pipe high-pressure intake mechanism includes: E-pipe support 1, first cylinder support 2, fir

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap