Battery module nickel sheet test subassembly

A battery module, nickel sheet technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of complex and cumbersome semi-automatic testing operations, prone to calibration errors, slow testing speed, etc., to avoid errors and avoid injuries. , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

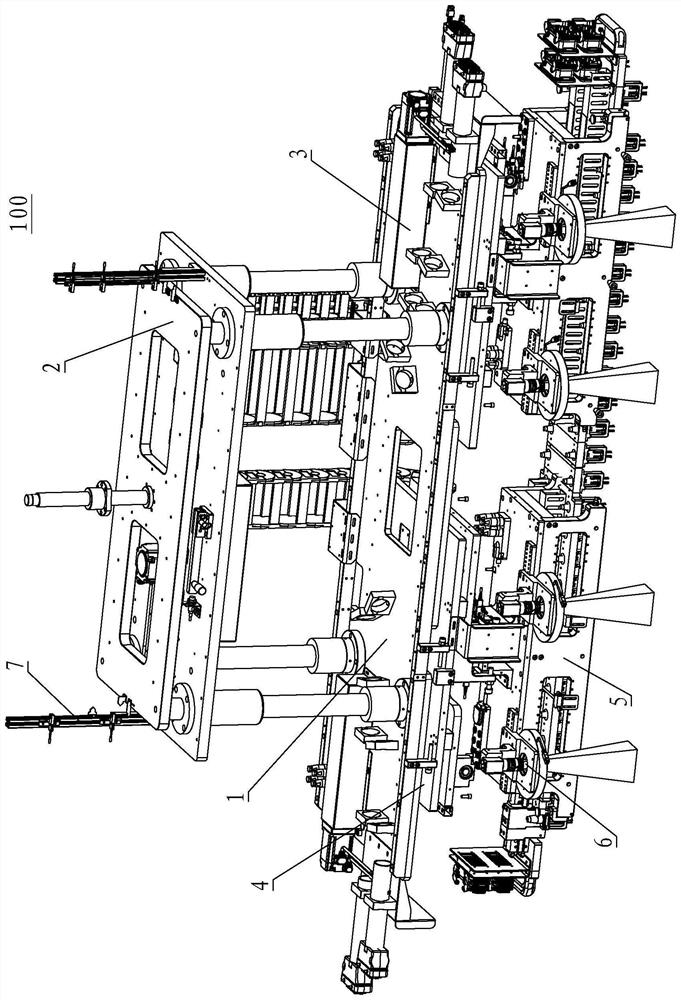

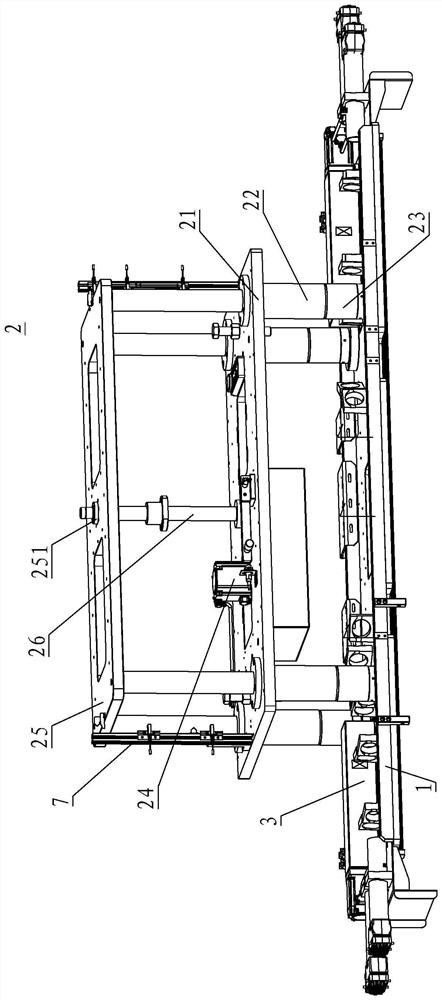

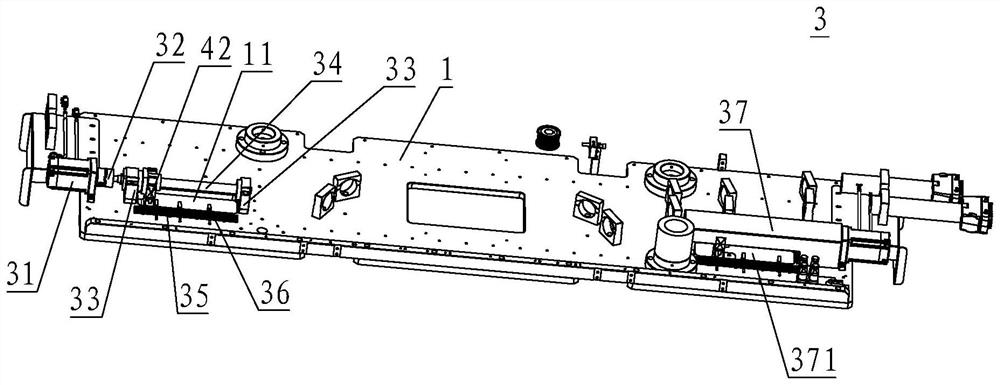

[0067] The embodiment of the present invention provides a battery module nickel sheet testing unit 100, which solves the problems in the prior art that manual testing is slow, prone to calibration errors, high-voltage safety hazards, semi-automatic testing operations are complicated and cumbersome, and misoperations are prone to cause danger. , and the technical problem that only one battery module can be tested at a time has achieved the technical effect of greatly improving the quality, safety and efficiency of the battery module nickel sheet test.

[0068] The technical solution in the embodiment of the present invention is to solve the above problem, and the general idea is as follows: by setting the vertical transmission mechanism 2, the horizontal transmission mechanism 3, the rotation mechanism 4 and the camera module 6, the test module 5 is automatically aligned with the Nickel strips are positioned and calibrated to avoid errors caused by manual testing, so as to improve

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap