High voltage ceramic capacitance couple sensor with low partial discharge magnitude

A partial discharge, high-voltage ceramic technology, applied in the direction of testing dielectric strength, can solve problems such as space cramps, and achieve the effect of low partial discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

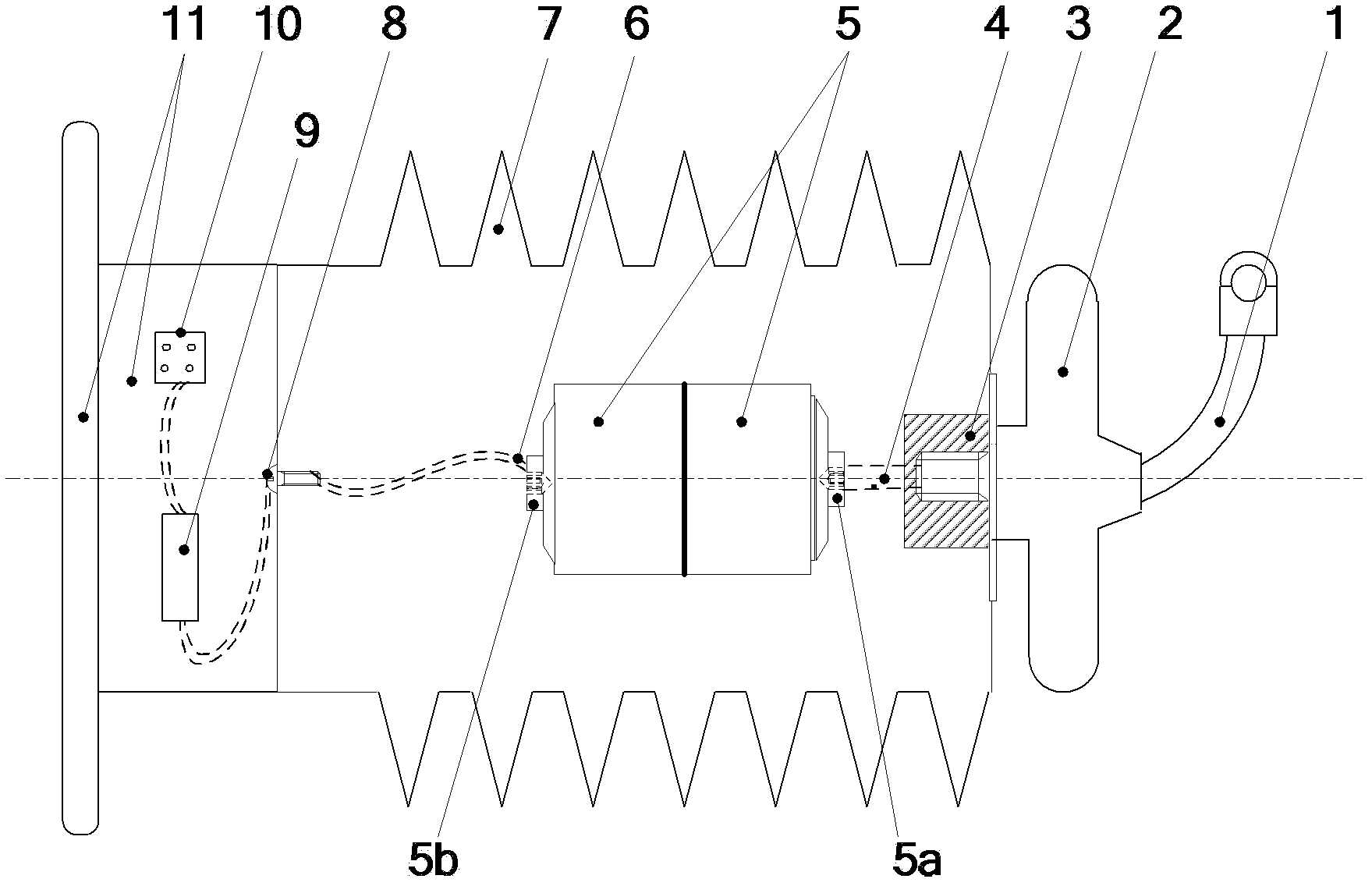

[0028] Such as figure 1 The shown high-voltage ceramic capacitive coupling sensor with low partial discharge includes a metal base 11, a ceramic capacitor core 5, an upper electrode 3, a metal electrode 2 and an external lead 1, the metal base 11 is a copper base, and the metal electrode 2 is Copper electrodes, the external lead wire 1 is used to firmly connect with the generator outlet busbar, so that the sensor and the generator busbar are connected together. The ceramic capacitor core 5 has two upper and lower copper electrodes, which are respectively the upper copper electrode 5a and the lower copper electrode 5b A metal rod 4 is installed between the upper copper electrode 5a of the ceramic capacitor core body 5 and the upper electrode 3, the metal rod 4 is preferably a copper rod, and the lower copper electrode 5b of the ceramic capacitor core body 5 is connected with the lead bolt 8 by a metal strip 6, The metal strip 6 is a copper strip, the lead bolts 8, the metal strip

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap