Method for treating wastewater generated during production of 12-hydroxy stearic acid

A technology for the production of hydroxystearic acid and waste water, which is applied in natural water body treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., and can solve the problem that enterprises cannot bear, the treatment effect is not ideal, and the value of material is obtained Issues such as reasonable and effective utilization are not met, so as to achieve a high degree of overall automation, enhance product competitiveness, and achieve sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

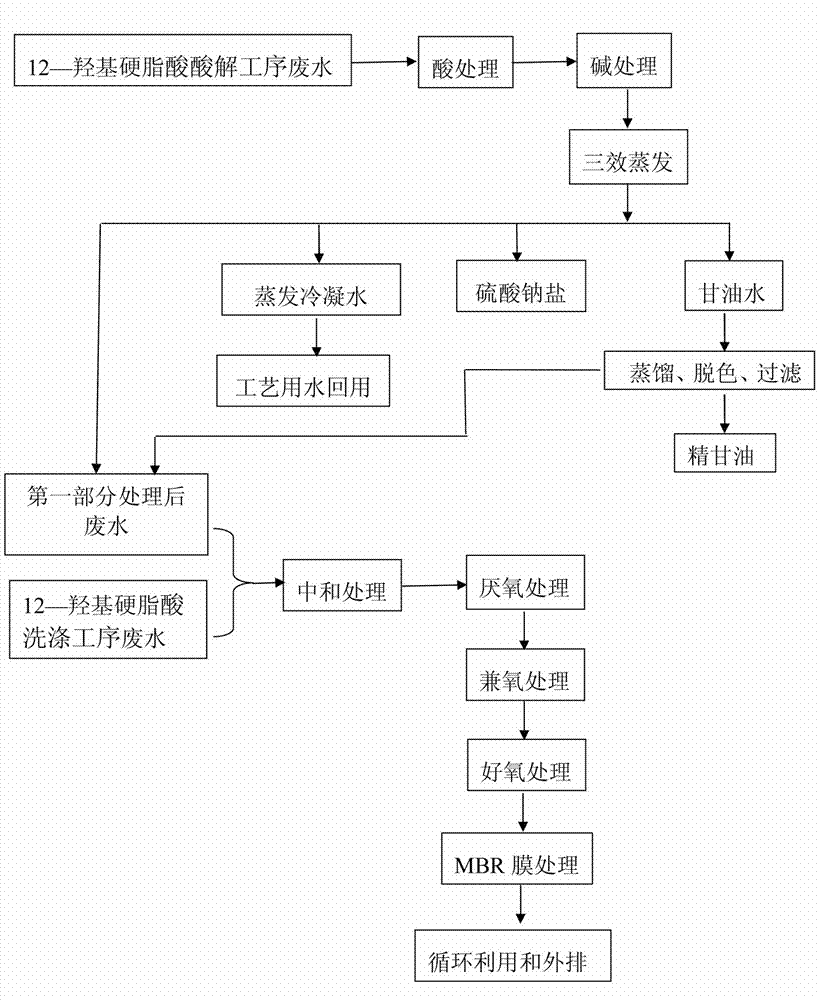

[0036] Attached below figure 1 The production wastewater treatment method of 12-hydroxystearic acid provided by the present invention will be described in detail below.

[0037] As attached figure 1 As shown, a 12-hydroxystearic acid production wastewater treatment method, the specific treatment process includes the following two parts:

[0038] The first part is the recycling treatment of wastewater from the acid hydrolysis process. The specific operation steps include:

[0039] A. Acid treatment of wastewater from the acid hydrolysis process: 1) Use a submerged pump to transport the acid-containing water in the pool to the acid treatment tank; 2) Heat to keep the temperature of the material liquid at 50°C, and remove it in a static state Suspended impurities on the upper part of the water surface; 3) Stir the material liquid with compressed air, add 48% liquid caustic under stirring, adjust the pH value of the material liquid to 4; 4) Add the purifying agent ferric chloride, and react

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap