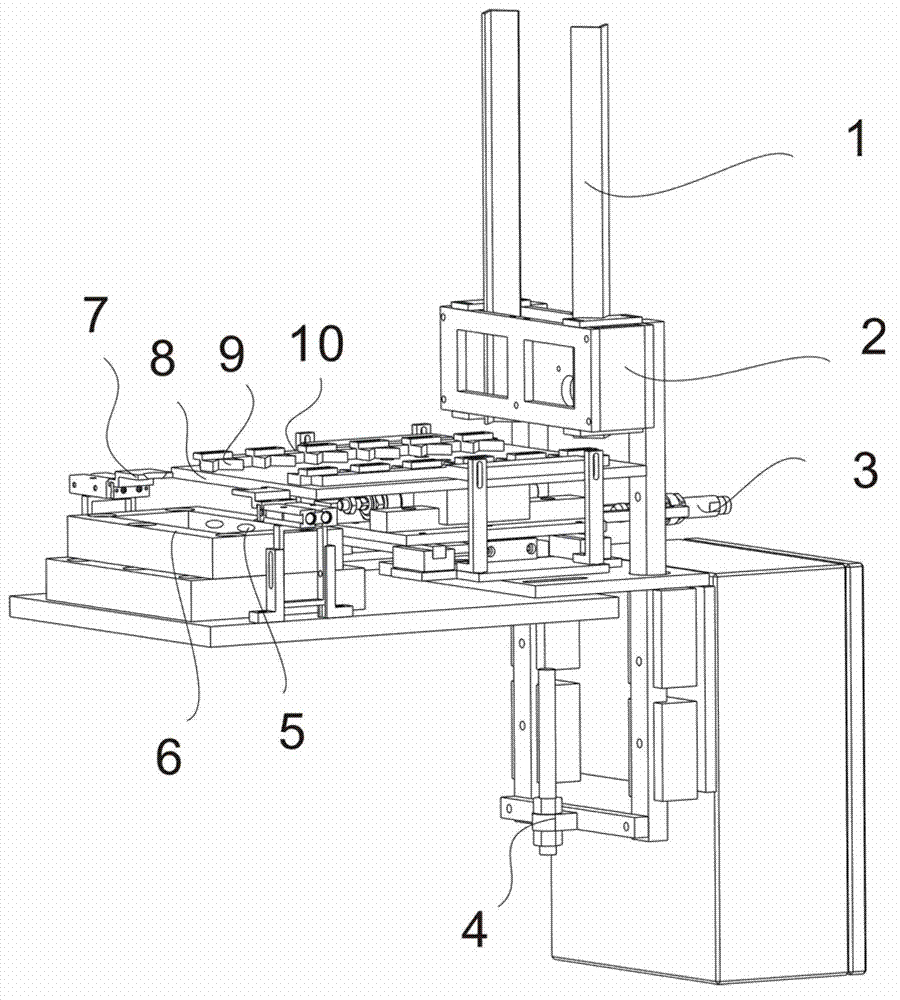

Automatic flat grinding machine for manufacturing tableware

A flat grinder and tableware technology, which is applied in the direction of machine tools, grinders, and manufacturing tools suitable for grinding workpiece planes, can solve the problems of reduced grinding accuracy, inability to move two-dimensionally, and low work efficiency, so as to improve work efficiency, The effect of avoiding production accidents and improving grinding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0014] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail with reference to the accompanying drawings and the best embodiments.

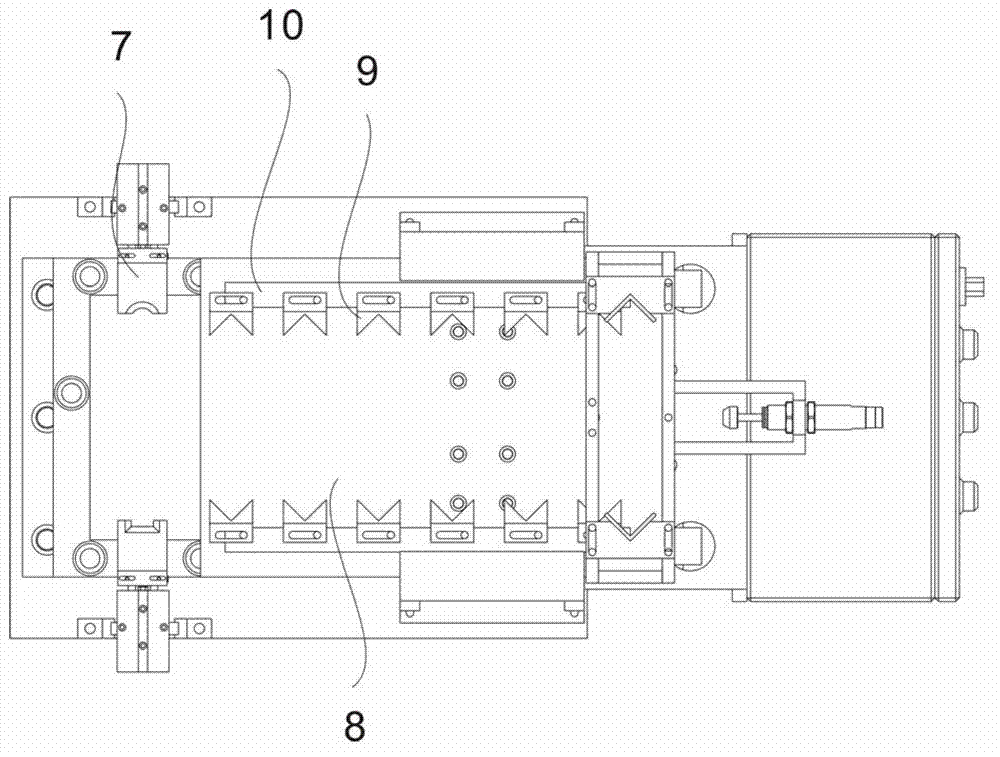

[0015] Such as figure 1 As shown, the present invention includes a base 8, a two-dimensional movable seat 9 provided on the base, and two sets of upper and lower grinding wheel grinding mechanisms that are driven up and down by an opening and closing cylinder 7 arranged on the upper side of the two-dimensional movable seat. The upper and lower grinding wheel grinding mechanism includes an upper grinding wheel 4, a lower grinding wheel 2 driven by a motor 6, and upper and lower soap dispensers fixed on the rotating seat of the grinding wheel. The angle formed by the upper and lower soap dispensers is It is 90-150 degrees. The upper and lower soap dispensers include a soap dispenser support 3, and a soap dispenser 1 which is arranged on

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap