Refreshing method of aluminum profile combined porthole extrusion die

A technology of aluminum profiles and a new method, which is applied in the field of refurbishment of aluminum profile extrusion shunting combination dies, can solve problems such as excessive wear, short service life of extrusion dies, waste of labor and transportation electric energy, and reduce production costs. The process is simple and the effect of saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

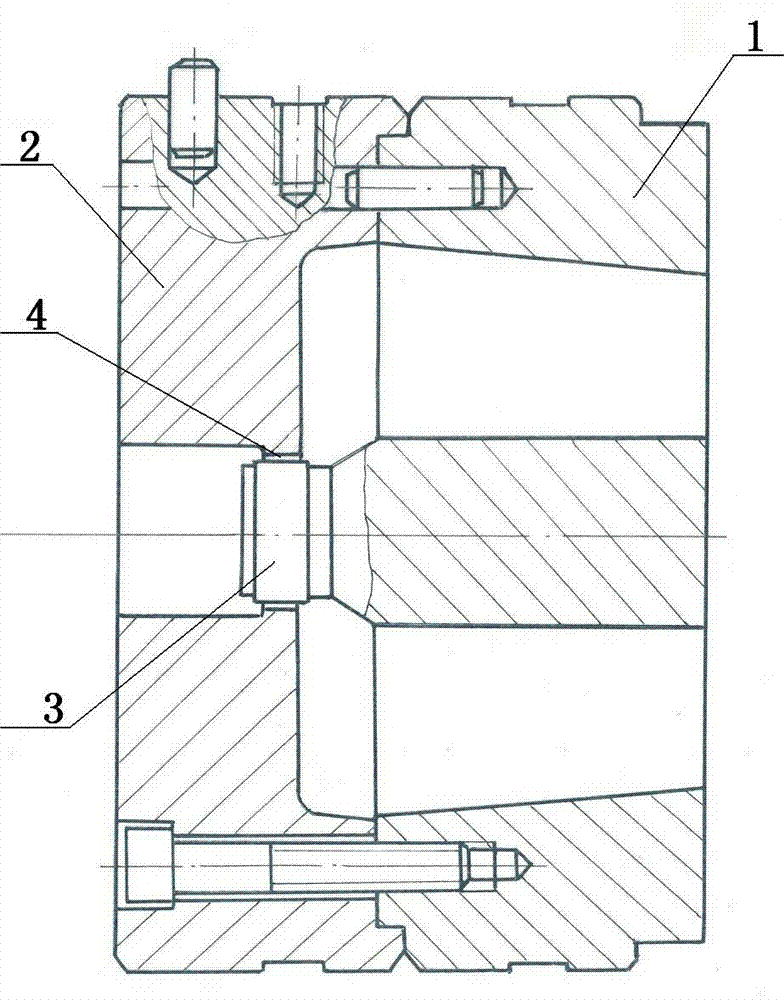

[0019] Reference attached Figure 1~5 , Aluminum profile extrusion splitter combined die is assembled by precise assembly of upper die and lower die. The upper mold has an upper mold body 1, the upper mold body 1 is provided with an upper mold tongue 3 in the middle, the lower mold has a lower mold body 2, and the lower mold body 2 is provided with a lower mold inner cavity 4 in the middle.

[0020] The restoration method of the aluminum profile extrusion splitter combined die is as follows:

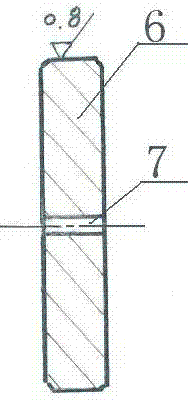

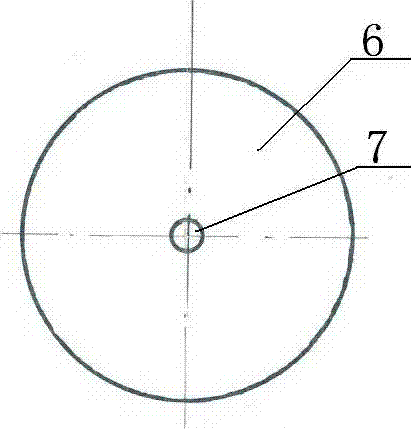

[0021] Use an EDM machine to press the inner cavity 4 of the failed lower mold to release 15-20mm on the single side of the maximum diagonal of the cavity, and process it into a round hole or a special-shaped hole with a depth of 20-30mm to make the lower mold Hole 5, the lower mold hole is counterbored, the surface roughness Ra 0.8μm, the same kind of high-strength heat-resistant alloy or better than the same kind of steel is made of the same shape as the lower mold hole hole shape insert 6, i

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap