Method for controlling particle size of compressed-leached material of zinc sulfide concentrate

A zinc sulfide concentrate, pressure leaching technology, applied in the direction of improving process efficiency, etc., can solve the problems affecting the completeness of the concentrate reaction, damage to the agitator of the adjustment tank, and unfavorable resource utilization, so as to improve resource utilization, The effect of avoiding wrapping and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] Example 1

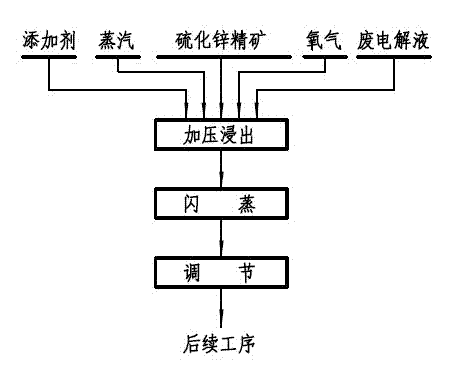

[0024] A method for controlling the particle size of zinc sulfide concentrate pressurized leaching material, the method is implemented in the following equipment: the equipment includes a reactor, a flash tank connected to the reactor, and an adjustment tank connected to the flash tank; Including the following steps:

[0025] (1) The pulp is fed into the reactor; the reaction conditions in the reactor are as follows: reaction time is 1-2h, stirring speed is 75-90r / min; temperature is 150℃; pulp acidity is 30g / L; oxygen pressure is 1200 kPa (G) The addition rate of the additive is 1.5 kg / t; the additive is composed of calcium lignosulfonate and hardwood tannin extract at a mass ratio of 1:1;

[0026] (2) The pulp discharged after the reaction in the reactor is sent to the flash tank for preliminary cooling. The pulp temperature during the discharge is 150°C; the pressure is 1200 kPa(g); the pulp temperature after the preliminary cooling is 120°C; The pressure

Example Embodiment

[0029] Example 2

[0030] An additive used in the method described in the embodiment, the additive is composed of calcium lignosulfonate and hardwood tannin extract at a mass ratio of 1:1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap