Clamp-free transformer winding and binding method thereof

A transformer winding and transformer technology, applied in the direction of transformer/inductor coil/winding/connection, coil manufacturing, etc., can solve the problem of not being able to press the coil with upper and lower clamps, so as to enhance the ability to resist short circuit and prevent displacement and deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

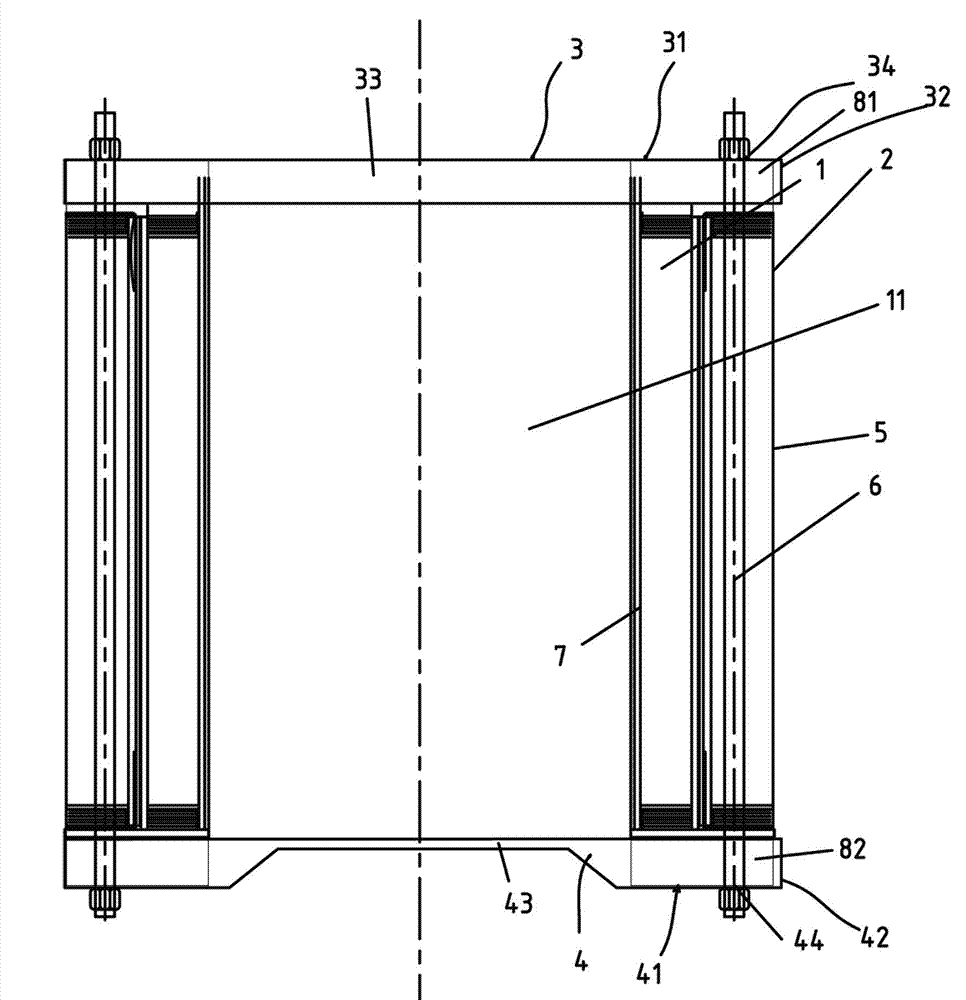

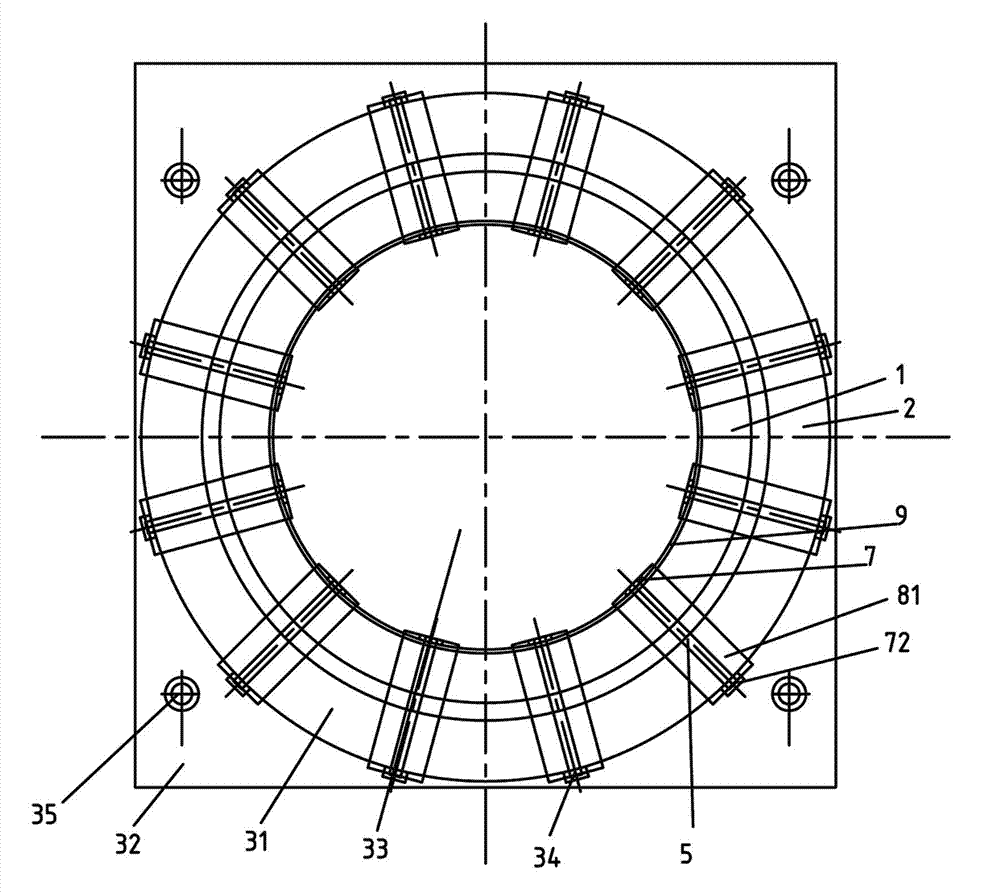

[0024] Refer to attached figure 1 ,Such as figure 2 As shown, a transformer winding without clips includes a coil with a hollow hole 11, a pressure plate 3 arranged on the upper part of the coil, and a supporting plate 4 arranged on the lower part of the coil. The pressing plate 3 and the supporting plate 4 are respectively set There are a first upper hole 33 and a first lower hole 43 corresponding to the hollow hole 11 of the coil, and the transformer winding also includes a plurality of cable ties 5 passing through the pressure plate 3 and the supporting plate 4 to tighten the coil. 5 are separately arranged along the circumferential direction of the coil.

[0025] The pressing plate 3 has a first upper portion 31 covering the coil and a second upper portion 32 extending out of the coil, the supporting plate 4 has a first lower portion 41 covering the coil and a second lower portion 42 extending out of the coil, the second lower portion 42 of the pressing plate 3 The s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap