Automatic printing method and system for bus stop sign boards

A bus stop sign and automatic printing technology, applied in the direction of digital output to printing unit, special data processing application, instrument, etc., can solve the problems of low efficiency, labor cost, high error rate and other problems of bus stop sign production, and achieve a unified production station cards, improve efficiency, and reduce the effect of error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention provides an implementation method and system for automatic printing of bus stop signs. In order to make the purpose, technical solutions and effects of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

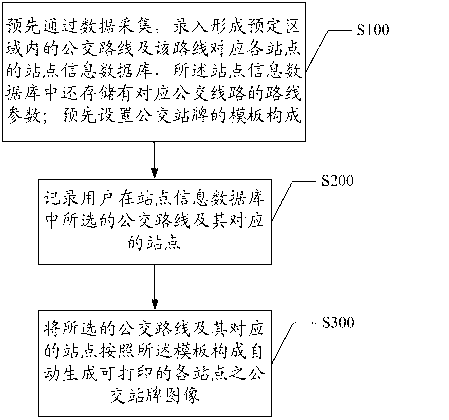

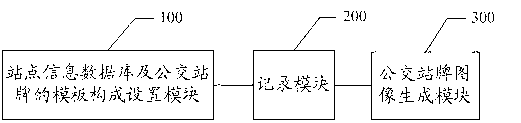

[0029] Such as figure 1 A method for realizing the automatic printing of a bus stop plate includes the following steps:

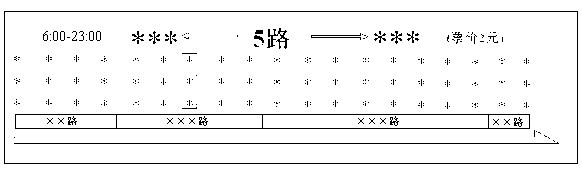

[0030] S100, through data collection in advance, enter and form the bus route in the predetermined area and the station information database corresponding to each station of the route, and the route parameters corresponding to the bus route are also stored in the station information database; the template composition of the bus stop board is preset .

[0031] The specific process is as follows: firstly, the station inform

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap