Efficient white light emission glass containing silver nanoparticles, and preparation method thereof

A silver nanoparticle, white light technology, applied in the field of solid luminescent materials and their preparation, can solve the problems of poor color rendering, coating and the like, and achieve the effects of low cost, simple glass components, and color difference resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Prepare materials according to the following molar ratios:

[0029] SiO 2 50%Al 2 o 3 20%

[0030] CaCO 3 20% Li 2 CO 3 10%

[0031] Eu 2 o 3 0.2% Ag 2 O 1%;

[0032] (2) After fully grinding the components prepared in step (1) until they are evenly mixed, melt at 1600°C for 1 hour under air atmosphere conditions, and finally undergo conventional molding and anneal at 680°C for 6 hours to obtain high-efficiency white light emission Glass containing silver nanoparticles, consisting of components in the following molar ratios:

[0033] SiO 2 50%Al 2 o 3 20%

[0034] CaO 20% Li 2 O 10%

[0035] Eu 2 o 3 0.2% Ag 2 O 1%.

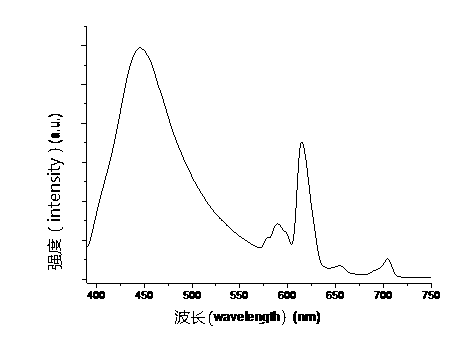

[0036] The glass is colorless and transparent glass, which emits bright white light under the excitation of 379nm ultraviolet light, and has good color rendering, such as figure 1 shown.

Embodiment 2

[0038] (1) Prepare materials according to the following molar ratios:

[0039] SiO 2 55%Al 2 o 3 20%

[0040] CaCO 3 20% Li 2 CO 3 5%

[0041] Eu 2 o 3 0.2% Ag 2 O 0.1%;

[0042] (2) After fully grinding the components prepared in step (1) until they are evenly mixed, melt at 1580°C for 2 hours under air atmosphere conditions, and finally undergo conventional molding and anneal at 700°C for 2 hours to obtain high-efficiency white light emission Glass containing silver nanoparticles, consisting of components in the following molar ratios:

[0043] SiO 2 55%Al 2 o 3 20%

[0044] CaO 20% Li 2 O 5%

[0045] Eu 2 o 3 0.2% Ag 2 O 0.1%.

Embodiment 3

[0047] (1) Prepare materials according to the following molar ratios:

[0048] SiO 2 60%Al 2 o 3 20%

[0049] CaCO 3 20% Li 2 CO 3 0%

[0050] Eu 2 o3 0.2% Ag 2 O 4%,

[0051] Among them, 0≤x≤10, 0.1≤y≤4;

[0052] (2) After fully grinding the components prepared in step (1) until they are evenly mixed, melt at 1550°C for 3 hours under air atmosphere conditions, and finally undergo conventional molding and anneal at 550°C for 8 hours to obtain high-efficiency white light emission Glass containing silver nanoparticles, consisting of components in the following molar ratios:

[0053] SiO 2 60%Al 2 o 3 20%

[0054] CaO 20% Li 2 O 0%

[0055] Eu 2 o 3 0.2% Ag 2 O 4%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap