Steel plate butt welding positioning device and counterpoint method

A welding positioning and positioning device technology, applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problem of fine-tuning the gap between two steel plates and the fine adjustment of coplanarity, warping and deformation of steel plates, and non-destructive testing of welds. Qualified and other issues, to achieve the effect of convenient construction, improve precision and save construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

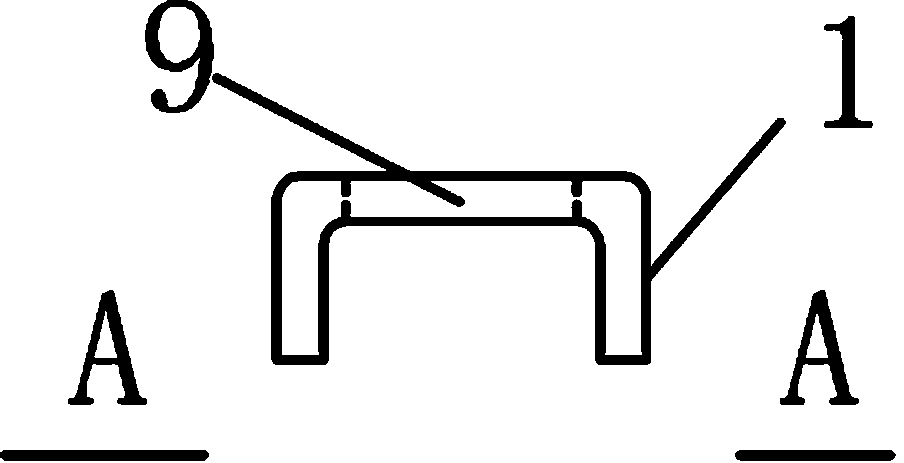

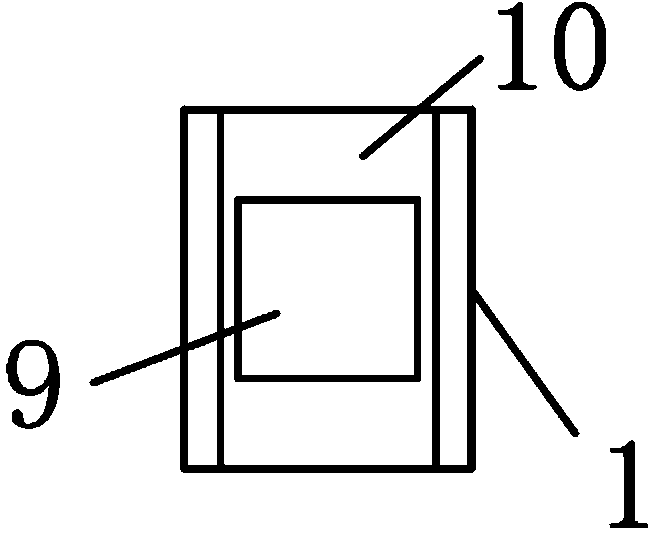

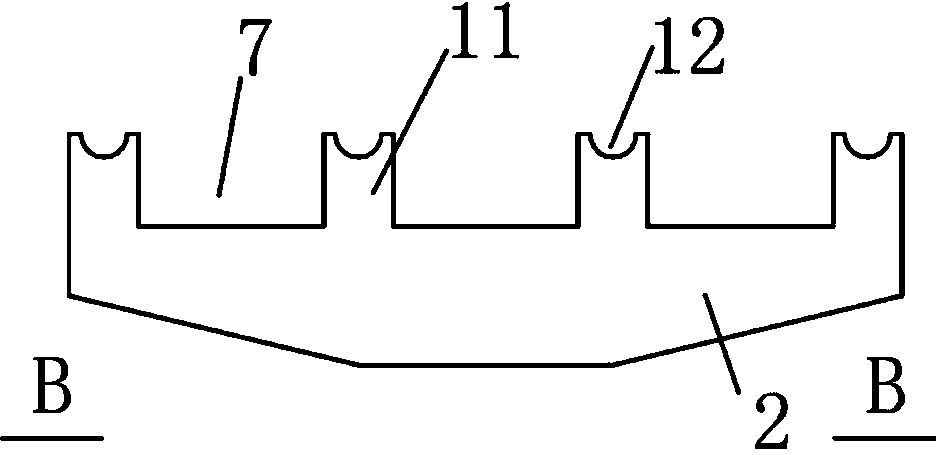

[0029] The structure of the present invention is as figure 1 -12: A steel plate butt welding positioning device. The positioning device includes a C-shaped bending plate 1, a connecting plate 2. The connecting plate 2 is provided with a groove 7 for fixing the C-shaped bending plate 1, and the C-shaped bending plate 1 is fixed In the groove 7, a connecting plate 2 and two C-shaped bending plates 1 are welded together to form a connecting piece; the positioning device also includes a shear key 3, which is welded to the steel plate that needs to be butt connected, The anti-shear key 3 is provided with a circular hole 8, and the bolt 4 is inserted into the circular hole 8 of the anti-shear key 3.

[0030] A bent plate hole 9 is provided on the bottom surface 10 of the C-shaped bent plate 1 opposite to the opening. The bent plate hole 9 is larger than the shape of the shear key 3, and the shear key 3 can pass through the bent plate hole 9.

[0031] The method for positioning the butt weld

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap