Color steel plate plastic coating equipment with transverse high-voltage static bar

A horizontal high-voltage, electrostatic bar technology, applied to the surface coating device, coating and other directions, can solve the problem of powder accumulation, interference, etc., to achieve the effect of uniform coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

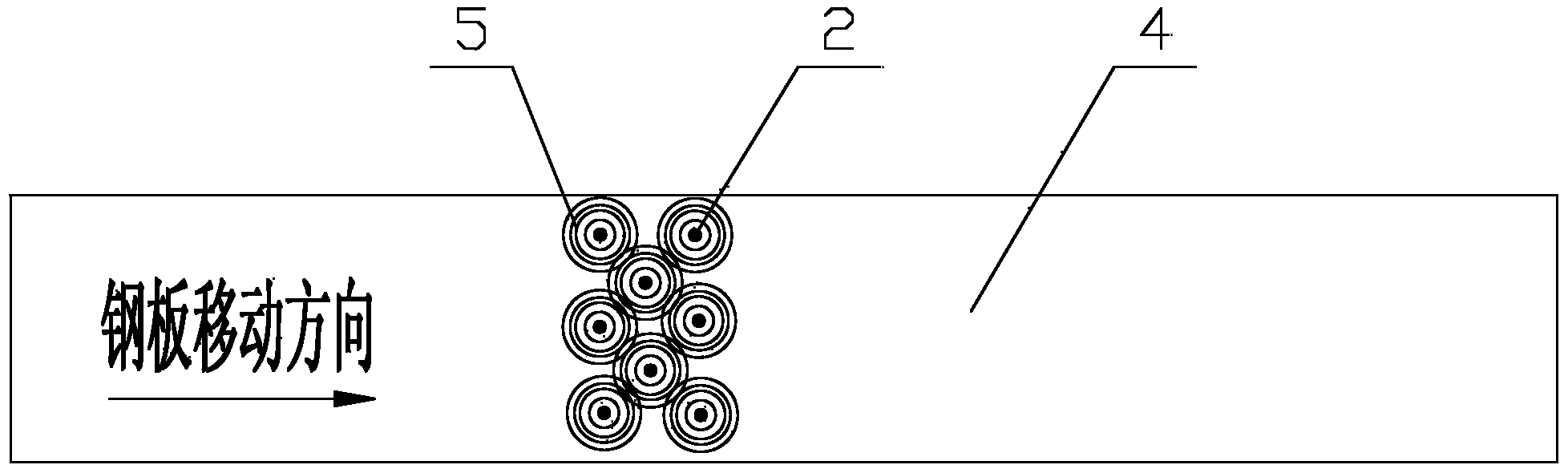

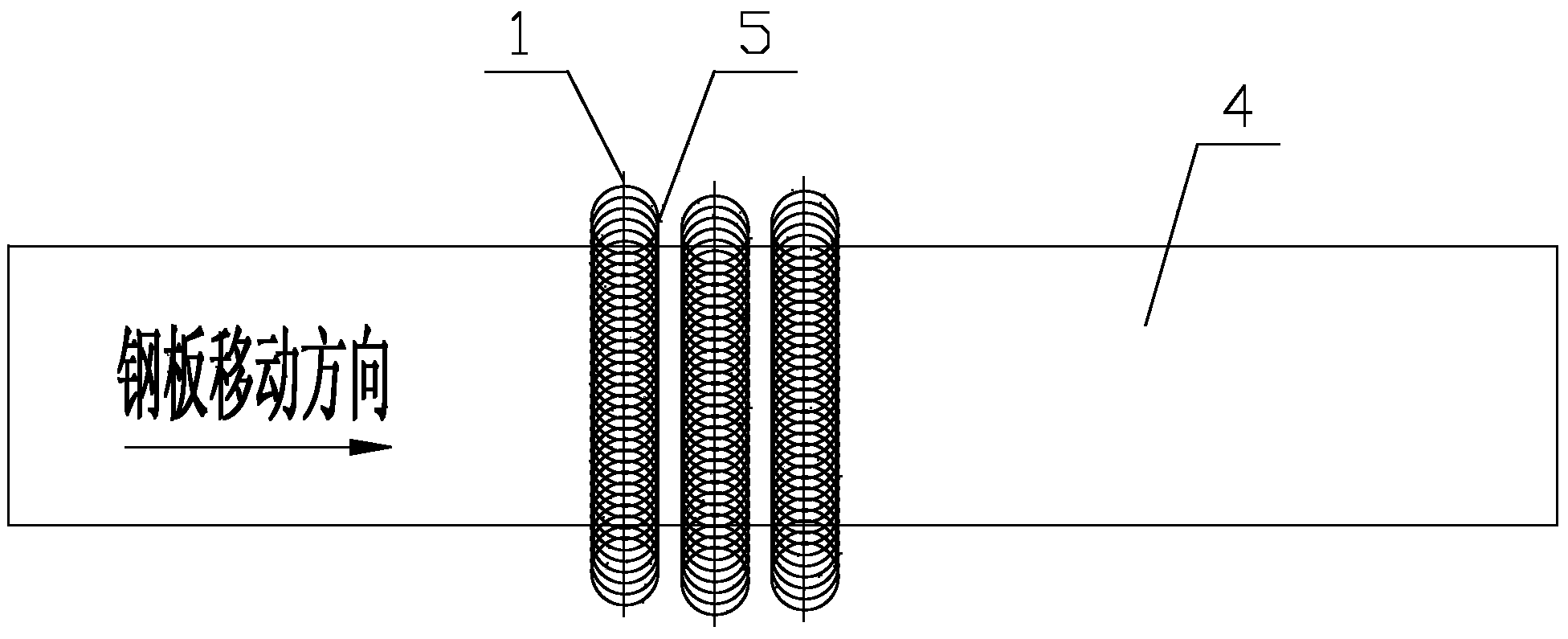

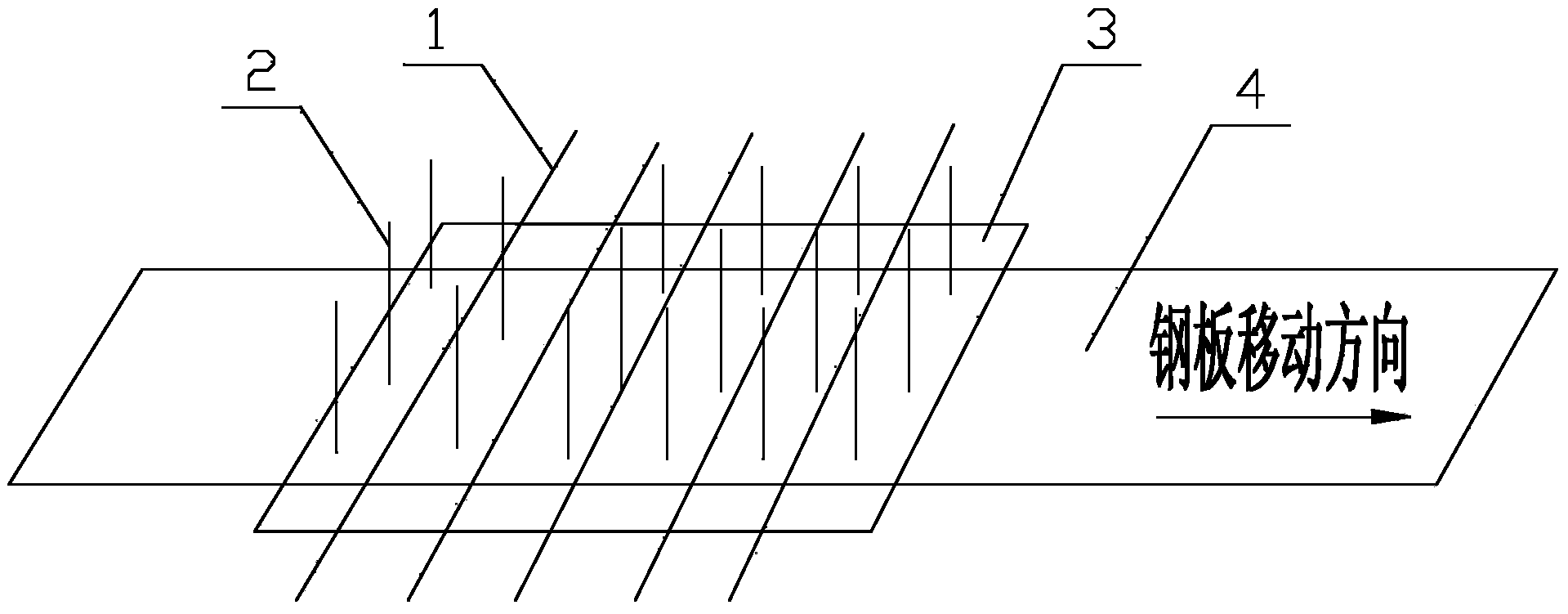

[0023] Horizontal high-voltage electrostatic bar color steel plate plastic coating equipment, such as Figure 1 to Figure 4 As shown, it includes an electrostatic bar 1 and a spray gun 2 , the spray gun 2 is located above the steel plate 4 , and the electrostatic bar 1 is parallel to the plane where the steel plate 4 is located. The direction of the current in the electrostatic bar 1 is perpendicular to the moving direction of the steel plate 4 . The electrostatic bar 1 is arranged above the steel plate 4 .

[0024] A screen 3 is arranged between the spray gun 2 and the steel plate 4 . After the spray gun 2 sprays for a long time, powder accumulation will inevitably occur on the spray gun 2. The screen 3 can prevent the powder accumulation on the spray gun 2 from falling directly on the steel plate 4, thereby affecting the spraying effect of the steel plate 4. Similarly, the electrostatic bar 1 is also arranged above the screen 3 .

[0025] The mesh size of the sieve 3 is 5-50

Embodiment 2

[0030] The difference between this embodiment and embodiment 1 is that the static bar 1 is arranged between the screen 3 and the steel plate 4 . The electrostatic bar 1 is arranged obliquely, and the direction of the current in the electrostatic bar 1 forms an included angle with the moving direction of the steel plate 4 . That is, the direction of the current in the electrostatic bar 1 is different from the moving direction of the steel plate 4. There are four electrostatic bars 1, and the four electrostatic bars 1 are arranged in parallel on the same plane. The powder sprayed from the spray gun 2 passes through the screen 3 and enters the static electricity The electrostatic area of the rod 1, so that the powder is charged, and when the powder contacts the steel plate, electrostatic adsorption occurs, thereby completing electrostatic spraying.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap