Elastic clamp applied to flat tongs for clamping special-shaped parts

A flat-nose pliers and irregular technology, which is applied in the field of mechanical processing clamping tools, can solve the problems of low positioning accuracy, low processing efficiency, and low precision of processed parts, so as to improve processing accuracy, improve processing efficiency, and improve positioning accuracy and repeatability of clamping accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

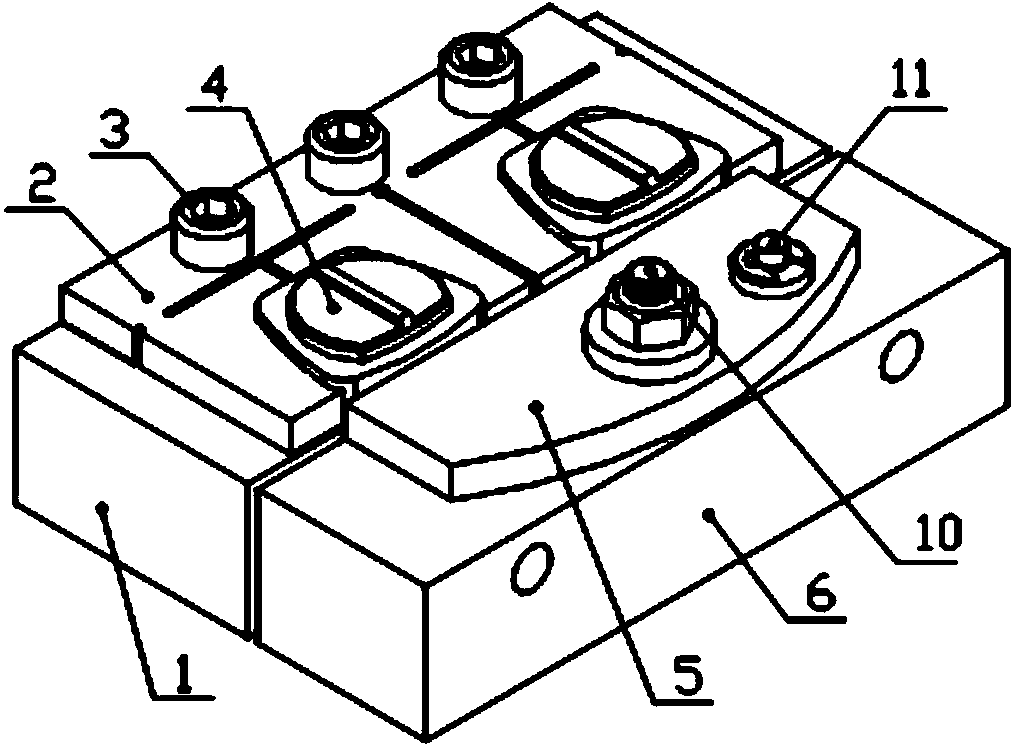

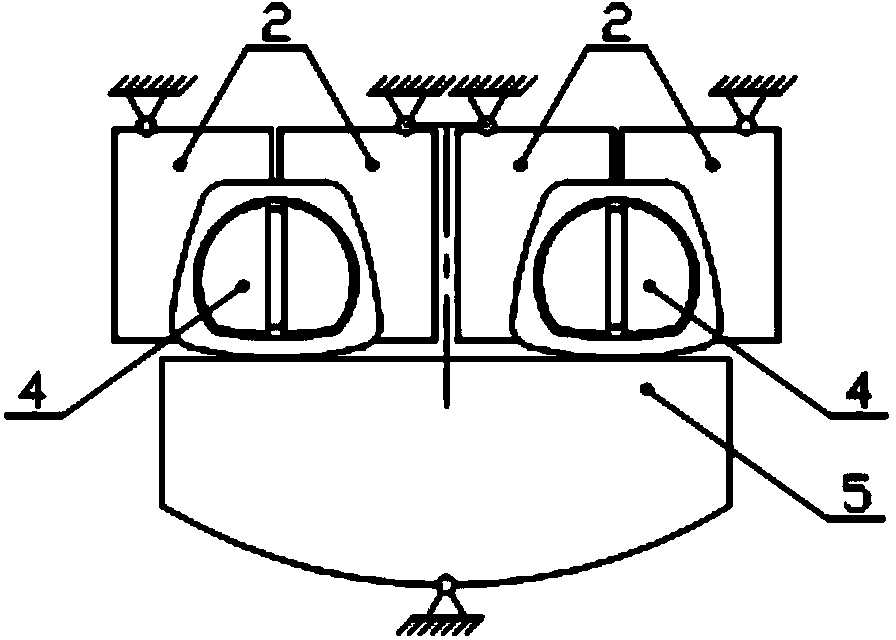

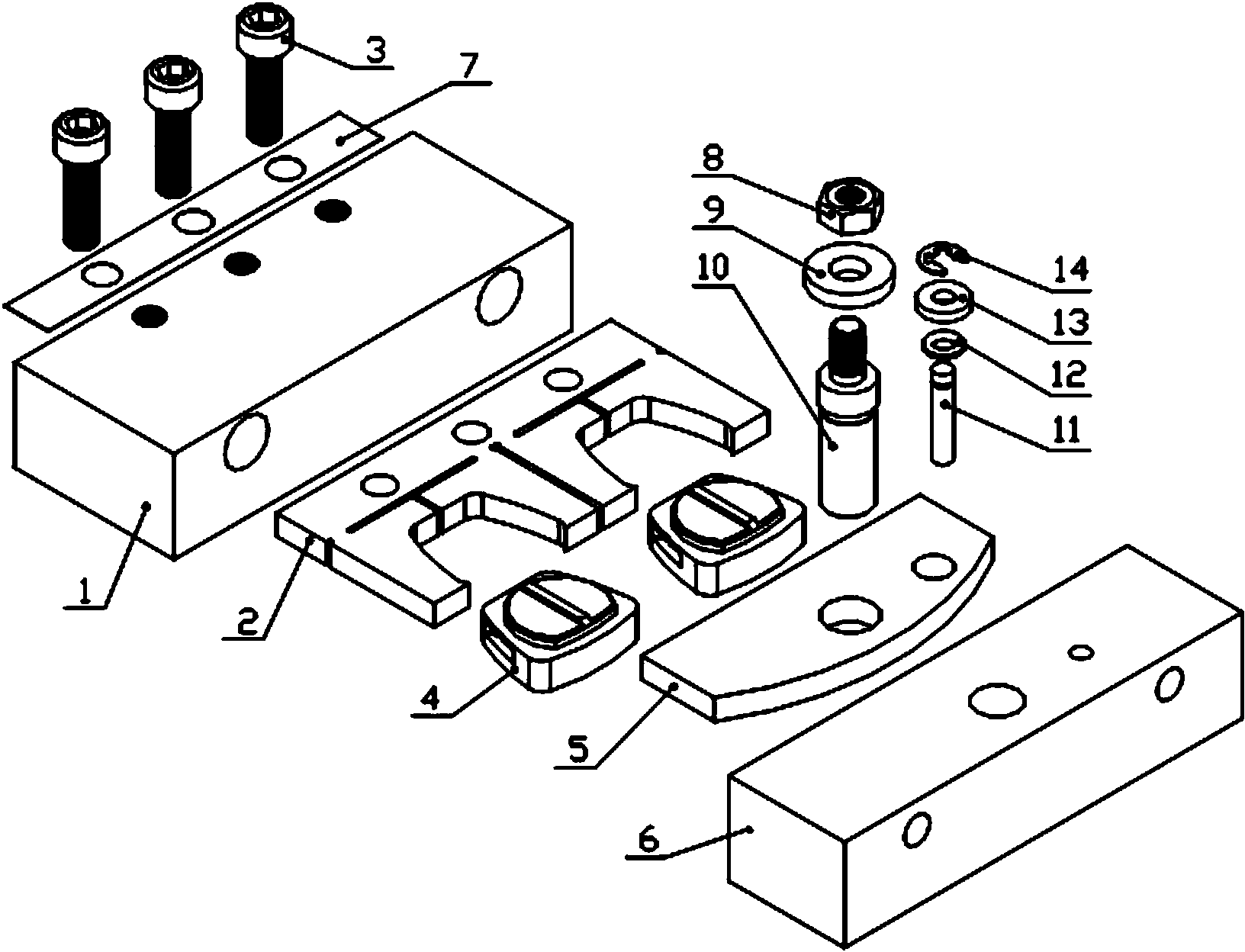

[0021] Such as figure 1 with figure 2 Shown is a schematic diagram of the structure and principle of the present invention, see the axonometric exploded view image 3 , See the two-dimensional structure Figure 4 , Figure 5 with Image 6 . In this embodiment, the structure of the elastic clamp used for clamping irregular-shaped parts on the flat-nose pliers is: the elastic jaw 2 is an integrated elastic structural board using a flexible hinge, and the plate is provided with a shape for placing the clamped part 4 The cavity and the double swing rod structure with flexible hinge; the elastic jaw 2 is fixed on the elastic jaw base 1 by the hexagon socket screw 3, and a copper washer 7 is placed between the elastic jaw 2 and the elastic jaw base 1; swing The jaw 5 is mounted on the swing jaw base 6 through the swing shaft 10, the swing jaw 5 can swing around the swing shaft 10, and the limit shaft 11 and the O-ring 12 realize the limit and reset during swing; the swing shaft 10 The

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap