Feeder for heating bar stock of mini-tiller

A technology of feeding device and tiller, which is applied in the direction of conveyor objects, transportation and packaging, etc. It can solve the problems of unstable manual feeding frequency and uneven heating, and achieve the effect of simple structure, uniform heating and stable frequency amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

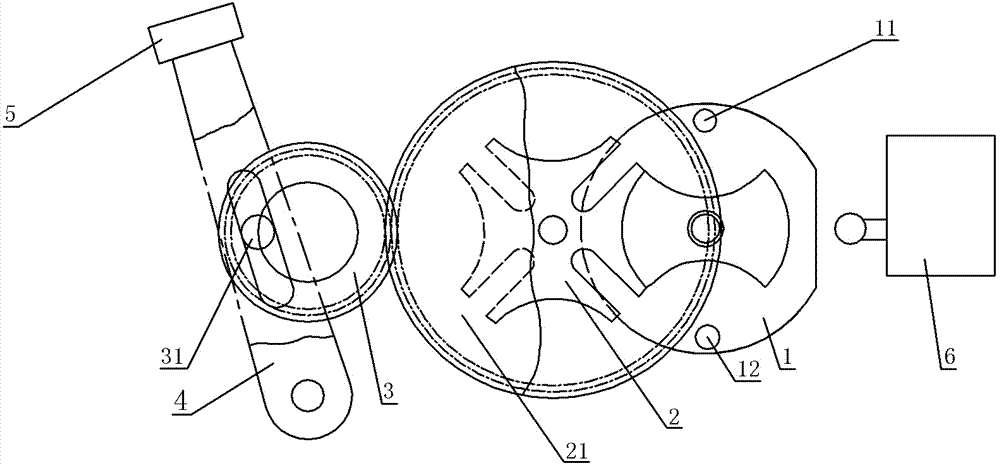

[0009] according to figure 1 As shown, the feeding device for bar heating of the tiller in the embodiment of the present invention includes a frame, and also includes a drive plate 1 that is rotatably connected with the frame, a four-index sheave 2 that is rotatably connected with the frame, and four The indexing sheave 2 coaxially fixes the first gear 21, the guide rod 4 hinged with one end of the frame, the second gear 3 meshed with the first gear 21, and the work clamp 5 threaded with the end of the guide rod 4 away from the frame , the driving disc 1 includes a circular plate and a notched disc with two mutually symmetrical locking arcs, the circular plate includes an arc segment and a straight line segment, and the circular plate is provided with a four-index sheave 2 near the edge. The first pin 11 and the second pin 12, which are mutually symmetrical about the center of the circular plate, the four-index sheave 2 matches the notch disc, the upper edge of the second gear 3

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap