Skid-mounting full integration LNG and LCNG remote monitor unattended filling station

A fully integrated and skid-mounted technology, which is applied in the direction of equipment loaded into pressure vessels, container discharge methods, container filling methods, etc., can solve the problems of incomplete skid-mounted integration, high maintenance and operating costs, and demand for management personnel Multiple problems, to achieve the effect of software reliability, system optimization, and data resource sharing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

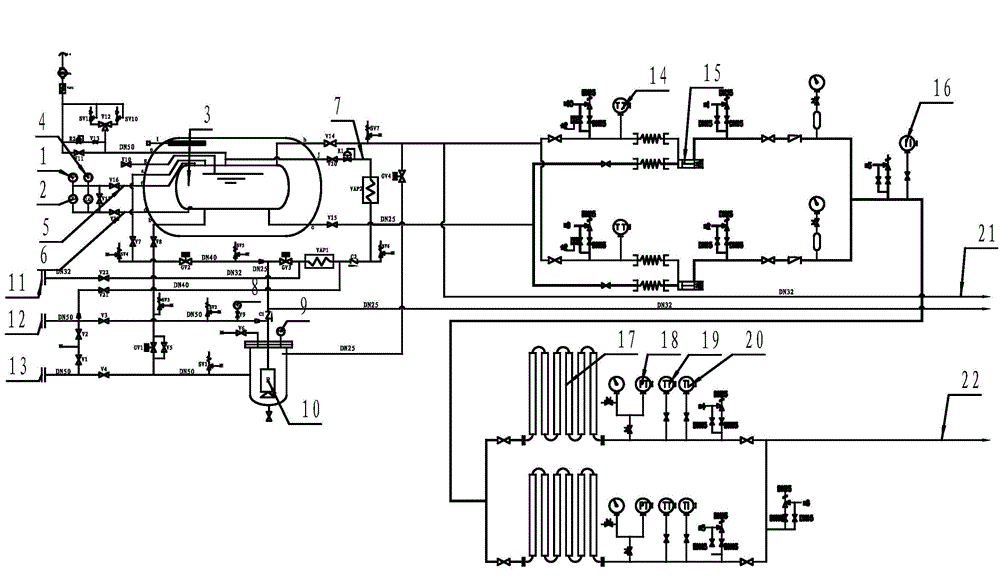

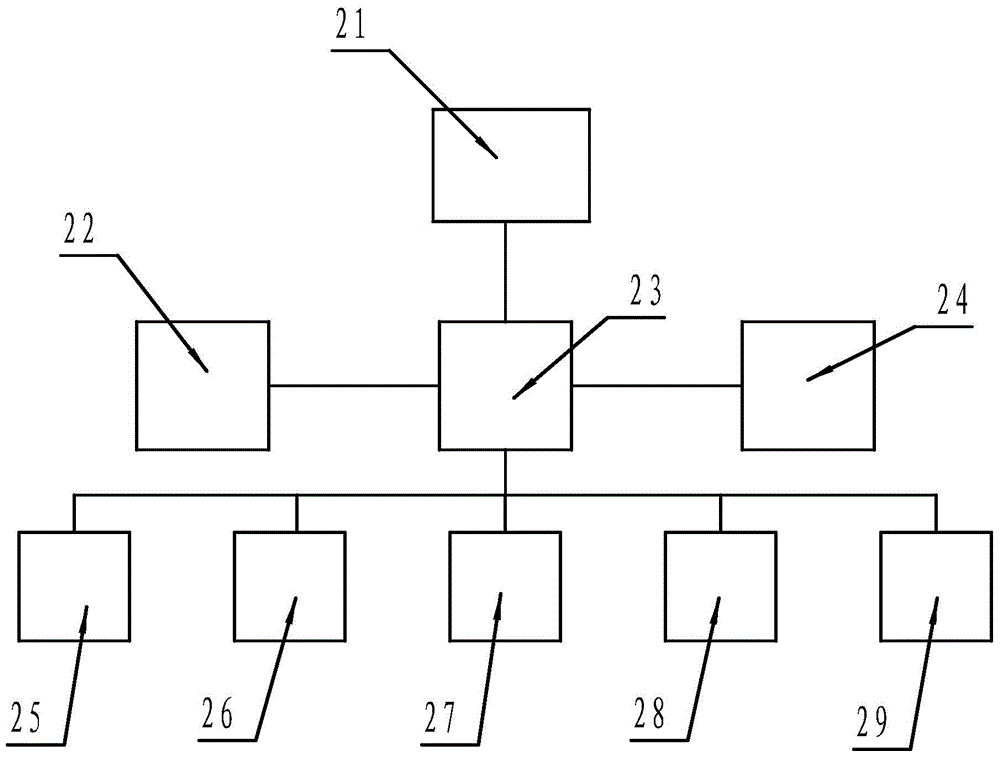

[0027] Embodiment 1, a skid-mounted fully integrated LNG and LCNG remote monitoring unattended refueling station, including LNG storage tank 3, pump skid, booster skid, and filling equipment installed on the skid body, is characterized by: The skid body is equipped with explosion-proof frequency conversion speed regulators connected with LNG submersible pump 10 and LCNG plunger pump 15 respectively, with explosion-proof electrical cabinets respectively connected with various electrical equipment, equipped with input terminals connected with sensors and control terminals The on-site substation of each valve using the PLC controller,

[0028] The on-site sub-station using PLC controller includes: LNG storage unit, LNG and LCNG drive unit, LNG and LCNG process control unit, LNG and LCNG metering and filling unit, and equipment connected with host computer communication.

[0029] The LNG storage unit is connected to the pressure transmitter 1, the liquid level transmitter 2, the pres

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap